Anisotropic electric conduction material preparation method

A conductive material, anisotropic technology, applied in the field of anisotropic conductive material preparation, can solve problems such as complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention relates to a kind of preparation method of anisotropic conductive material, and this method comprises the following steps:

[0028] Step 1) preparation of particle composite system

[0029] Add 5 to 200 parts of ferromagnetic conductive fillers with an average size of 0.1 to 100 μm in 100 parts of thermosetting or thermoplastic organic monomers, stir and disperse at 20 to 250 °C for 0.5 to 10 hours; After the system is evenly dispersed, add 1 to 15 parts of curing agent or crosslinking agent and continue stirring for 30 seconds.

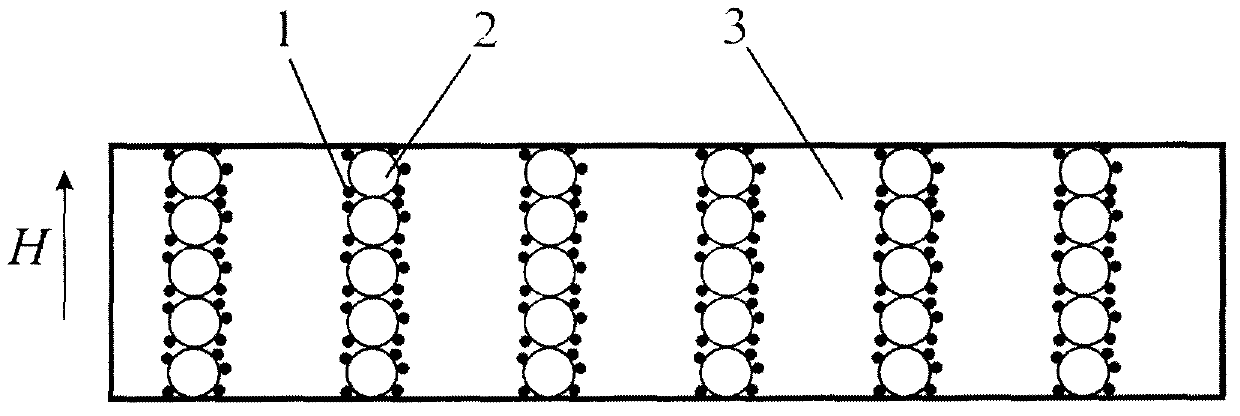

[0030] Step 2) Orientation of Magnetic Particles in Magnetic Field

[0031] The dispersion composite system is injected into the mould, and then a magnetic field is applied at the mould, the magnetic field strength is 0.01-2.0T, and the orientation time is 1-60min.

[0032] Step 3) Curing

[0033] Place the oriented and formed sample in an oven for curing, the temperature of the oven is 20-200°C, and the temperature is...

Embodiment 1

[0038] Add 10 parts of carbon black / Fe with an average particle size of 0.1 μm to 100 parts of unsaturated polyester monomer 2 o 3 For ferromagnetic conductive filler, stir and disperse in a water bath at 20°C for 5 hours; after the system is uniformly dispersed, add 5 parts of cross-linking agent styrene, and continue stirring for 30 seconds.

[0039] The dispersion composite system is injected into the mold, and then a magnetic field is applied at the mold, the magnetic field is generated by an electromagnetic coil, the magnetic field strength is 0.1T, and the orientation time is 5min.

[0040] Put the oriented sample into an oven for curing, the temperature of the oven is 20°C, and the temperature is kept for 480h.

[0041] The prepared sample has dense structure, low porosity and smooth surface. Metallographic observation is carried out to the prepared sample of example 1, find the carbon black / Fe in the polymer matrix 2 o 3The ferromagnetic conductive fillers are dist...

Embodiment 2

[0043] Add 5 parts of carbon fiber / Fe ferromagnetic conductive filler with an average diameter of 0.1μm to 100 parts of epoxy resin monomer, stir and disperse in a water bath at 60°C for 0.5h; after the system is uniformly dispersed, add 15 parts of curing agent Polyamide, continue stirring for 30s.

[0044] The dispersion composite system is injected into the mold, and then a magnetic field is applied at the mold. The magnetic field is generated by an electromagnet, the magnetic field strength is 0.8T, and the orientation time is 10 minutes.

[0045] Put the oriented sample into an oven for curing, the temperature of the oven is 80°C, and keep it warm for 20h.

[0046] The prepared sample has dense structure, low porosity and smooth surface. The metallographic observation of the sample prepared in Example 2 shows that the carbon fiber / Fe ferromagnetic conductive filler in the polymer matrix is distributed in chain-like clusters along the direction of the external magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com