Production method of flavored wine

A production method and technology for seasoning wine, applied in the field of seasoning wine production, can solve problems such as poor cellar foundation, improper cellar maintenance, different technological measures, etc., achieve low cost, enhance aging taste, and be beneficial to environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

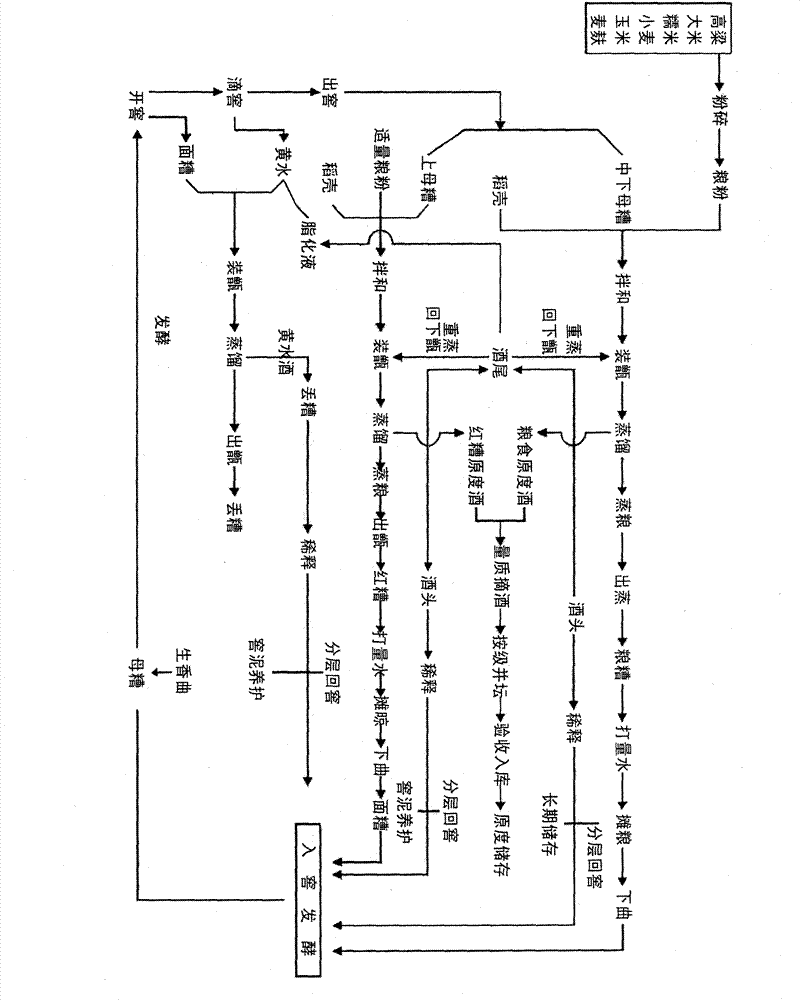

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with accompanying drawing, the brewing technological process of flavored wine of the present invention comprises the following steps:

[0028] A, 36 parts by weight of raw material grain sorghum, 20 parts of rice, 20 parts of glutinous rice, 14 parts of wheat, 8 parts of corn, 2 parts of wheat bran are pulverized and made into grain powder;

[0029] B. Mix grain powder with middle and lower grains and rice husks, put them in a retort, distill them, and then distill the original grain wine, pick the wine according to the quantity and quality, combine the altars according to the grade, check and put it into the warehouse, and store it in the original degree; among them, each The weight percentage of components is: 20% of grain powder, 79% of middle and lower mother grains and 1% of rice husk;

[0030] C. The remaining materials after the distillation in step B are steamed, grain grains are taken out, water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com