Engineering strain and application thereof to production of long-chain 3-hydroxy fatty acid

A technology of hydroxy fatty acid esters and engineering bacteria, which is applied in the field of genetic engineering and microbial fermentation, can solve the problems of complex process, high production cost, large production investment, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1. Construction of engineering bacteria

[0042] 1. Construction of recombinant plasmid pALgSC (a suicide plasmid for knocking out phaC1-phaZ-phaC2 in Pseudomonas Insectophila LAC25)

[0043] 1. Synthesize the double-stranded DNA molecule shown in sequence 4 of the sequence list, in which the 10th to 510th nucleotides are the upstream homologous fragment (named H1 fragment), and the 517 to 1366th nucleotides are Gentiana sulfate Resistance gene (also known as Gm r Genes, in which positions 523-1356 are open reading frames), and nucleotides 1372 to 1835 are downstream homologous fragments (named H2 fragments).

[0044] 2. Double-cut the double-stranded DNA molecule of step 1 with restriction enzymes HindIII and NheI, and recover the digested product.

[0045] 3. Double digest pK18mobsacB plasmid with restriction enzymes HindIII and NheI to recover the vector backbone (about 5.5kb).

[0046] 4. Connect the digested product of step 2 and the vector backbone of step 7 to obt...

Embodiment 2

[0073] Example 2. Production of medium and long-chain 3-hydroxy fatty acids using recombinant engineering strain LAC31 (pSPH09)

[0074] 1. Use recombinant engineering bacteria LAC31 (pSPH09) to produce 3-hydroxydecanoic acid

[0075] 1. Inoculate the recombinant engineered strain LAC31 (pSPH09) into 20mL LB medium (containing 50μg / mL kanamycin sulfate), incubate at 30°C and 200rpm for 12 hours to obtain a first-level seed solution.

[0076] 2. Inoculate the first-level seed solution obtained in step 1 into 4YLB medium containing 12g / L n-decanoic acid at 5% inoculum to obtain the initial system. In the initial system, the concentration of the recombinant engineered bacteria LAC31 (pSPH09) is OD600nm =0.45 (In actual applications, 0.3-0.6 can be used).

[0077] 3. Incubate the initial system obtained in step 2 at 30°C and 200 rpm for 48 hours to obtain a termination system.

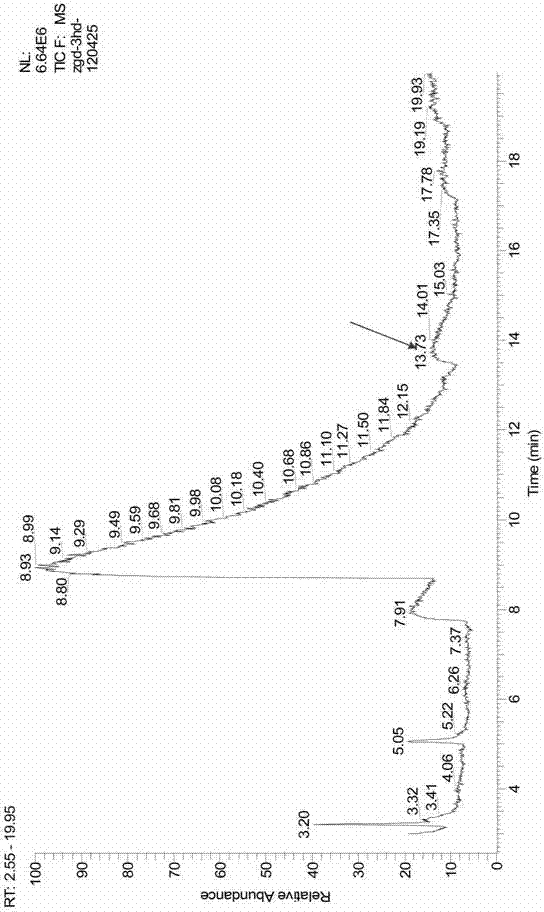

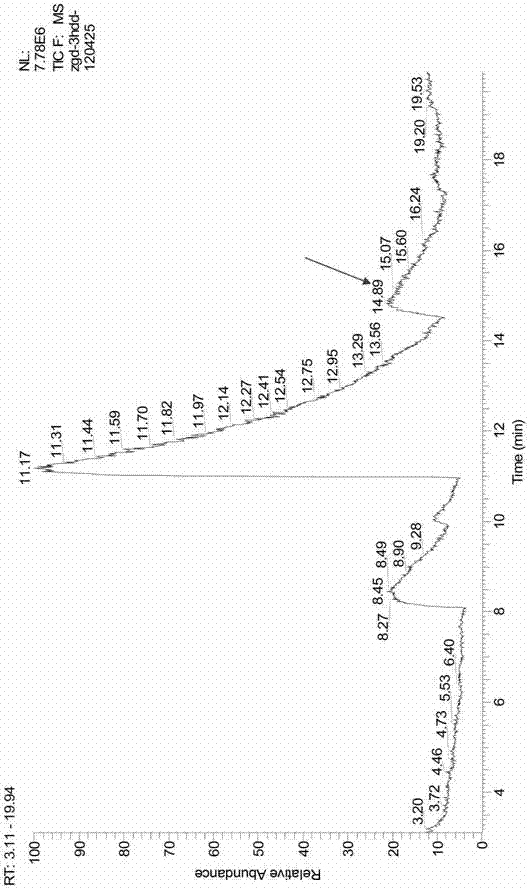

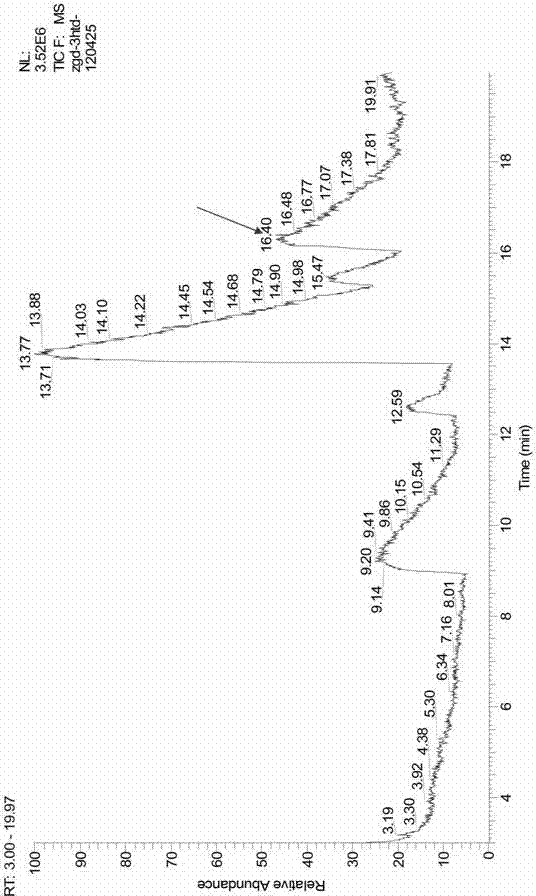

[0078] 4. Detect the dry weight of bacterial cells in the termination system and the content of 3-hydroxy fatty ...

Embodiment 3

[0095] Example 3. Production of medium and long-chain 3-hydroxy fatty acids using recombinant engineering strain LAC31 (pZGD01)

[0096] Recombinant engineered strain LAC31 (pZGD01) was used instead of recombinant engineered strain LAC31 (pSPH09). Others are the same as in Example 2.

[0097] With n-decanoic acid as the carbon source, the dry cell weight of the recombinant engineered strain LAC31 (pZGD01) after fermentation is 1.08±0.01g / L, the 3-HA concentration in the fermentation supernatant is 1.75±0.06g / L, and 3-HA The component of GC-MS detected as 3-HD. It is proved that the method of the present invention can be used for the fermentation production of high-purity 3-HD.

[0098] Using n-dodecanoic acid as the carbon source, the dry cell weight of recombinant engineered strain LAC31 (pZGD01) was 0.90±0.09g / L, the 3-HA concentration in the fermentation supernatant was 4.59±0.14g / L, and 3-HA The HA component was detected as 3-HDD by GC-MS. It is proved that the method of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com