Special multifunctional ion plating gun having compact structure

An ion plating gun with a compact structure, applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the difficult to achieve special coating requirements, large plasma vacancy area, difficult target replacement, etc. problem, to achieve the effect of easy promotion, compact and simple structure, simple, compact and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

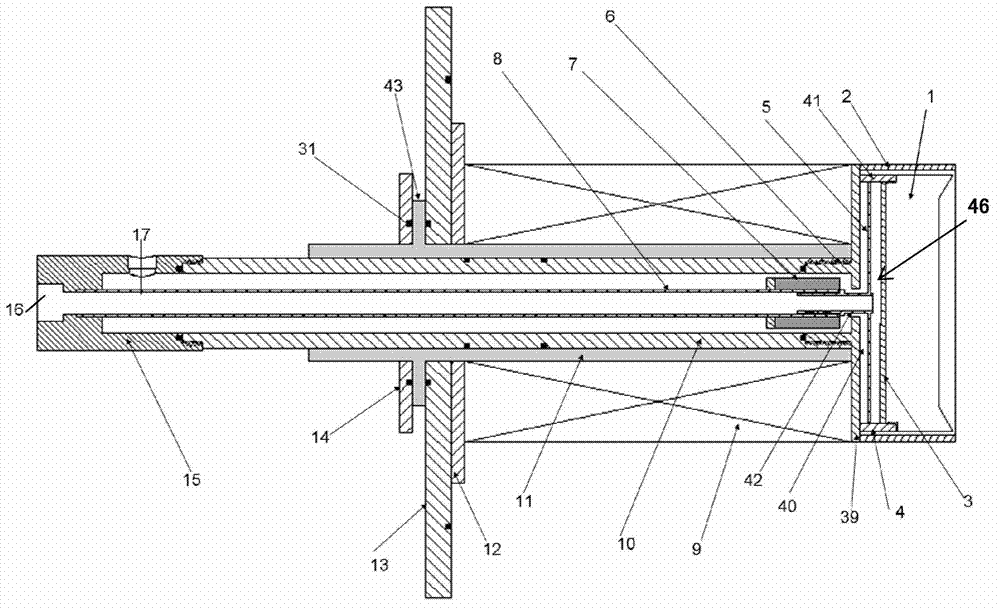

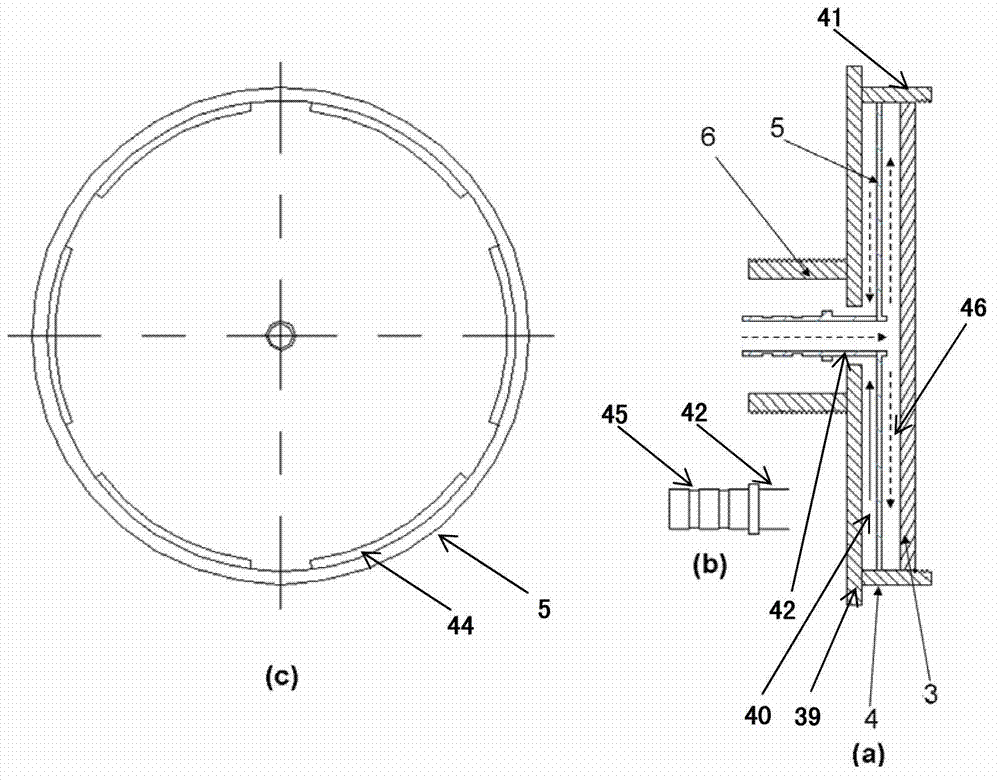

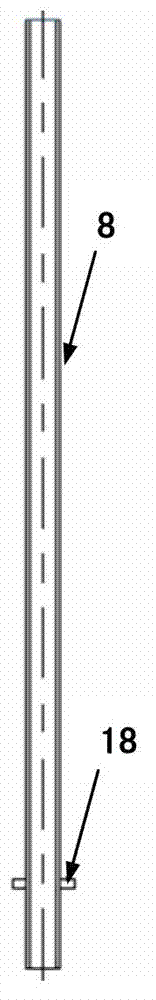

[0048] figure 1 It is a schematic diagram of the two-dimensional plane structure of the special multifunctional ion plating gun with a compact structure in Embodiment 1 of the present invention; as can be seen from the figure, the special multifunctional ion plating gun with a compact structure in Embodiment 1 of the present invention includes: a disc-shaped target material 1, Target shielding cover 2, target base cooling copper plate 3, target base 4, target base cooling channel partition 5, target bottom column connecting pipe 6, permanent magnet or magnetic ring 7, cooling water inlet pipe 8, Electromagnetic coil 9, target bottom column 10, target bottom column insulation cover 11, ion plating gun chassis insulation plate 12, ion plating gun chassis 13, ion plating gun chassis fastening plate 14, cooling water channel base 15, water inlet 16 , water outlet 17 etc., concrete structure is as follows:

[0049] The shape of the target 1 is disc-shaped, the size of the target i...

Embodiment 2

[0062] Figure 9 It is a schematic diagram of a two-dimensional plane structure of a special multifunctional ion plating gun with a cylindrical compact structure and a cylindrical target in Example 2 of the present invention; Figure 10 It is a schematic diagram of the distribution of the axial magnetic field around the cylindrical target in Example 2 of the present invention. The structure is similar to that of Embodiment 1, except that the target structure is a cylindrical target 33, and the electromagnetic coil 9 generates axial magnetic force lines 34, and between the axial magnetic force lines 34 is an intersection angle 38 between the magnetic field and the target; it can be seen that the axial divergence The magnetic field forms an acute angle with the cylindrical magnetic field pointing towards the top of the target. At the same time, a parallel component pointing to the top of the target is formed on the side of the cylindrical target. Therefore, driven by the magne...

Embodiment 3

[0064] Figure 11 It is a schematic diagram of a two-dimensional plane structure of a special multifunctional ion plating gun with a conical compact structure and a target material in Example 3 of the present invention; Figure 12 It is a schematic diagram of the distribution of the axial magnetic field around the conical target in Example 3 of the present invention; it is similar to Example 2, except that the target structure is a conical target 35, which proves the adaptability of the multi-target structure of the present invention, and the electromagnetic coil 9 Axial magnetic force lines 34 are generated, and an angle 38 between the axial magnetic force lines 34 is the intersection angle 38 between the magnetic field and the target. The conical target 35 has a truncated conical target cooling water chamber 36. In Embodiment 3, the target cooling copper plate 3 is modified, and it is set as a truncated conical structure matching the truncated conical target cooling water ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Gap size | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com