Novel quick tensioning construction method for front-blocked jack

A construction method and jack technology, applied in the erection/assembly of bridges, bridge materials, bridges, etc., can solve the problems of large anchor hole center distance, inability to adapt to the center, limited application fields, poor craftsmanship, etc. The effect of threading and speeding up work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

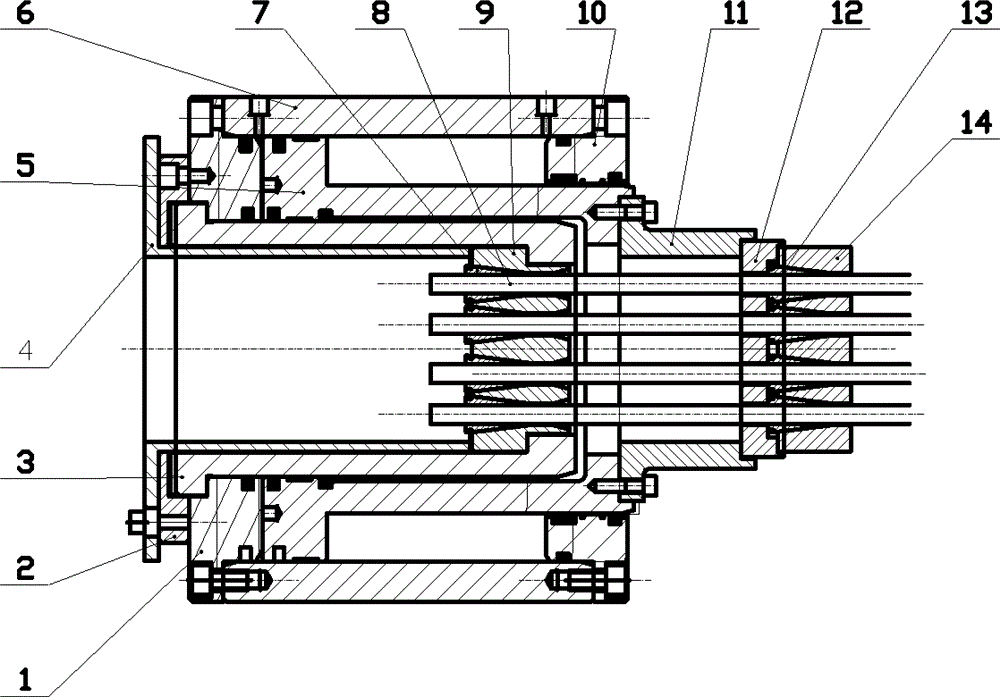

[0032] The following is a specific embodiment of the invention. The new kilocalorie jack used in this process step is composed of a rear cover 1, a gland 2, a through sleeve 3, a positioning sleeve 4, a piston 5, a cylinder body 6, a tool clip 7, a tool anchor 9 and a front cover 10. The accessories used It includes a transition extension sleeve 11, a limit plate 12, a working clip 13 and a working anchor ring 8, and the extension sleeve is an optional part.

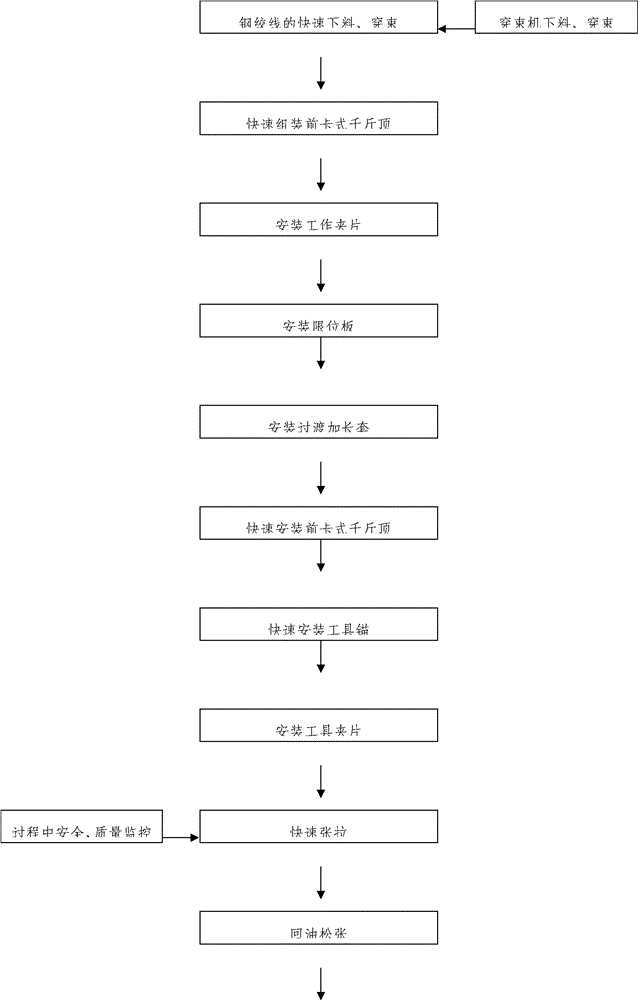

[0033] This embodiment comprises process steps as follows:

[0034] 1. Rapid cutting and threading of steel strands

[0035] The steel strands are threaded and unloaded by the CSJ15-1A steel strand threading machine.

[0036] 2. Quickly install the front clip jack accessories

[0037] ① Install the working clip 13: install the working clip 13 on the steel strand, and fasten the steel strand;

[0038] ②Installing the limit plate 12: install the limit plate 12 matching the diameter of the steel strand with accurate ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com