Airtight heat preservation steel plate silo and manufacturing method thereof

A steel plate and heat preservation technology, applied in the field of airtight heat preservation steel plate silos and their manufacturing fields, can solve the problems of inability to fumigate and kill insects, unsuitable for long-term storage, poor air tightness, etc., achieve good heat preservation and heat insulation effect, and reduce the amount of steel used. , the effect of ensuring the safety of grain storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

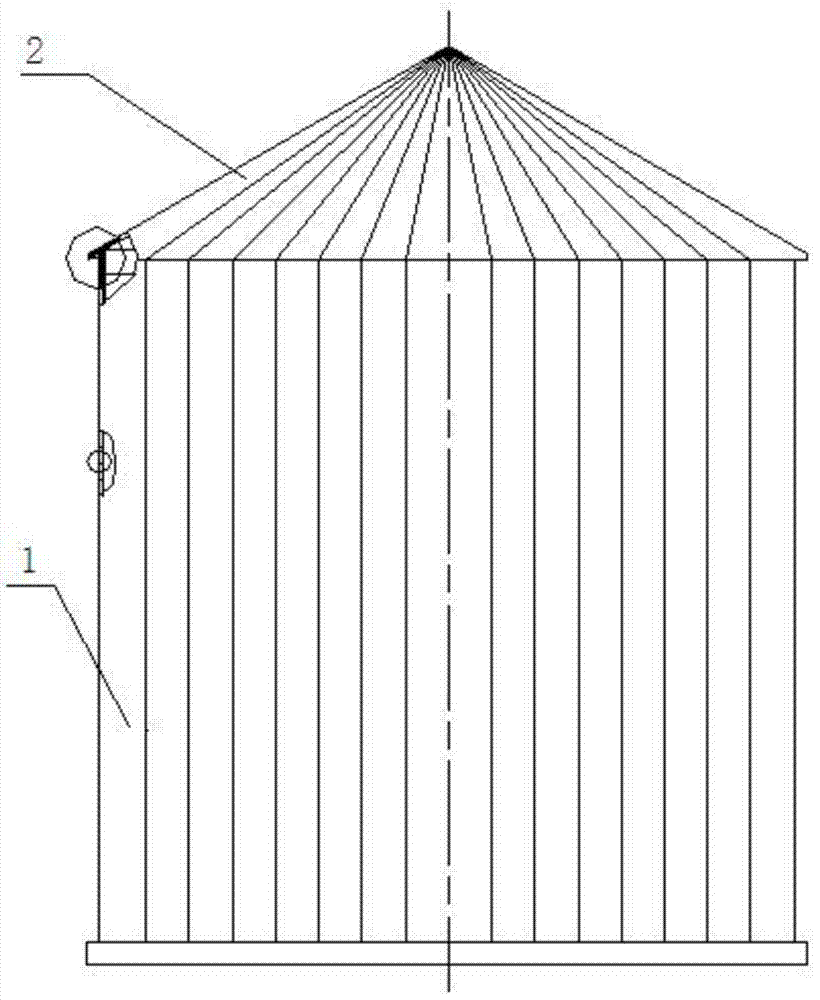

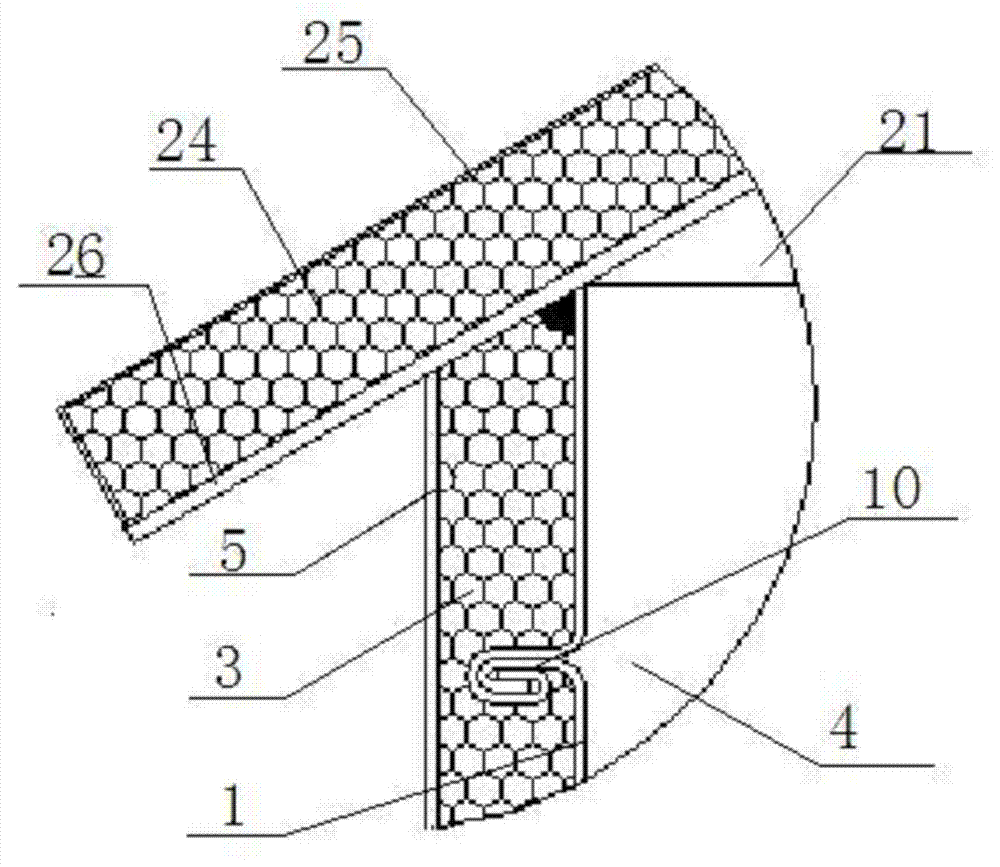

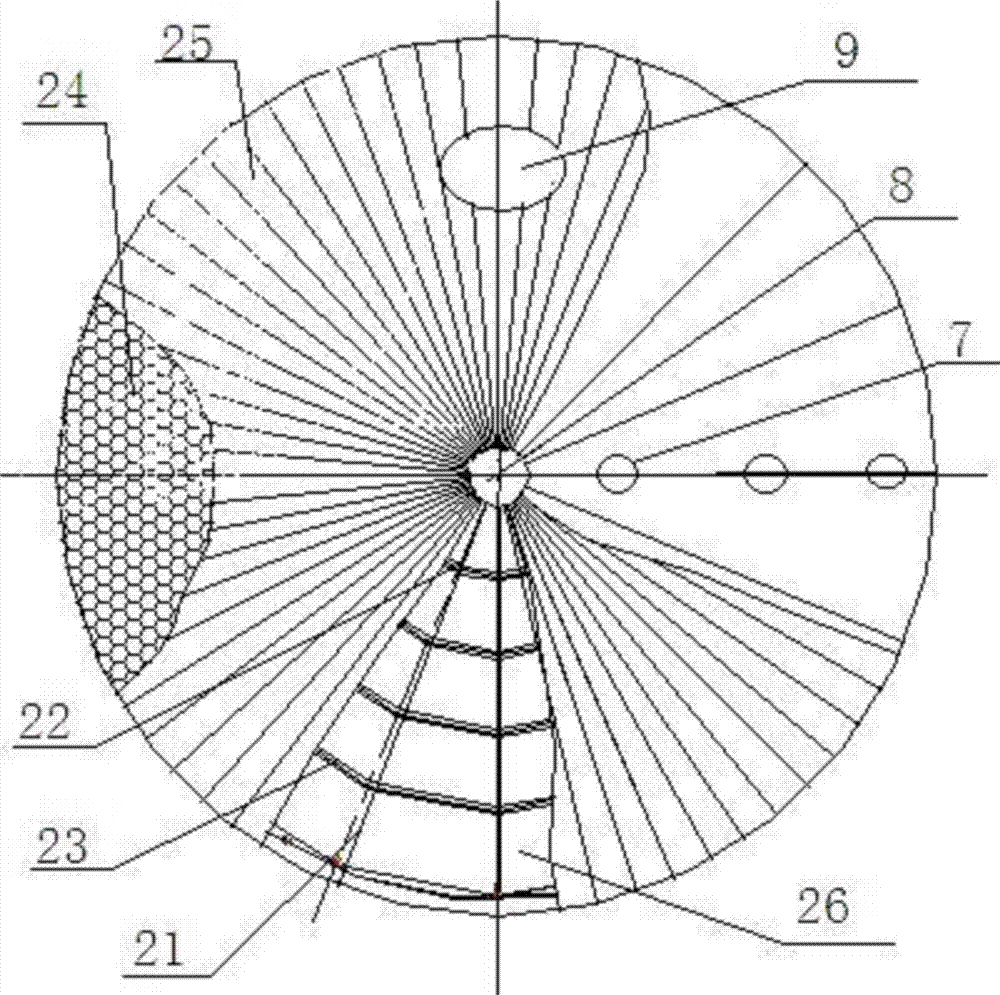

[0042] The airtight and heat-insulating steel silo comprises: an inner cylinder, the inner cylinder includes a silo 1 and a silo roof 2, and the silo roof and the silo are connected by welding, and the connection structure is continuous welding. There is an insulation layer 3 on the outside of the inner cylinder, the inner cylinder is connected to the column 4, the outer cylinder 5 is on the outside of the insulation layer, and the roof of the warehouse is an integral welded structure.

Embodiment 2

[0044] In the above-mentioned airtight and heat-insulating steel silo, the silo is a wall of a spiral steel plate bite structure, and the upper and lower layers are connected by a spiral coiling machine, and the coiling structure at the position of the bite 10 is 5 layer or 7 layer mouth.

Embodiment 3

[0046] In the above-mentioned airtight and heat-insulating steel silo, the wall panels of the cylinder wall are connected by bolts to form an assembled cylinder wall, and the joints of the wall panels are attached with seals 6 . The sealing member 6 is a sealing film or a sealing plate, which is attached to the sealing port by a sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com