High-adaptability scraping ring

A technology of compliance and scraping ring, which is applied in the field of piston rings, can solve the problems of insufficient ability of oil scraping ring to conform to the deformation of cylinder bore, decline of oil scraping ability and sealing performance, increase of engine oil consumption and air leakage, and achieve enhanced gas Improves tightness, improves compliance, and reduces particle emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

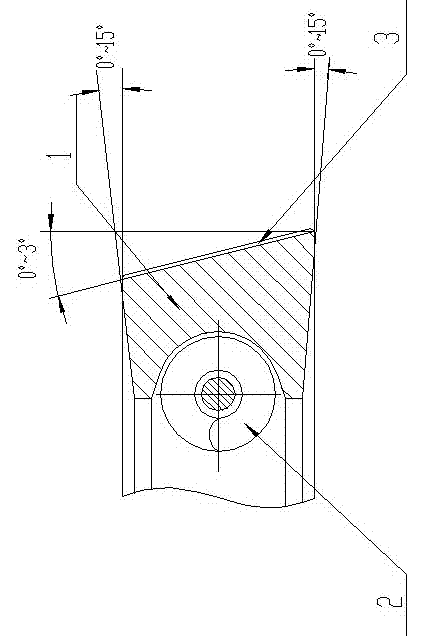

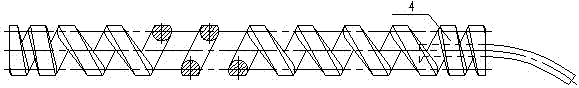

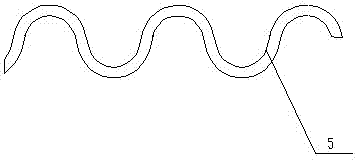

[0015] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the structure of the present invention is a combined structure of scraper ring main body 1 + inner support spring 2. The outer circular surface 3 of scraper ring main body 1 is a conical surface with a taper between 0° and 3°. The end surface of scraper ring main body 1 The shape is divided into rectangle, wedge, and trapezoid. The surface treatment of the outer circular surface 3 of the scraper ring main body 1 includes: hard chrome plating, chrome-based ceramic composite plating, chrome-based diamond composite plating, molybdenum spraying, nitriding and no coating and other coatings and coatings. layer; such as figure 2 As shown, the inner support spring is a helical support spring 4 (including equal distance, variable distance, etc.); image 3 As shown, the inner support spring is a wave support spring 5. By adopting the invention, the complian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com