Insulation method of aluminum back plate in photovoltaic module

A photovoltaic module and aluminum backplane technology, which is applied in the photovoltaic field, can solve the problems of difficult to withstand high voltage and poor insulation of aluminum backplane, and achieve the effect of improving the insulation and voltage resistance performance and avoiding high investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

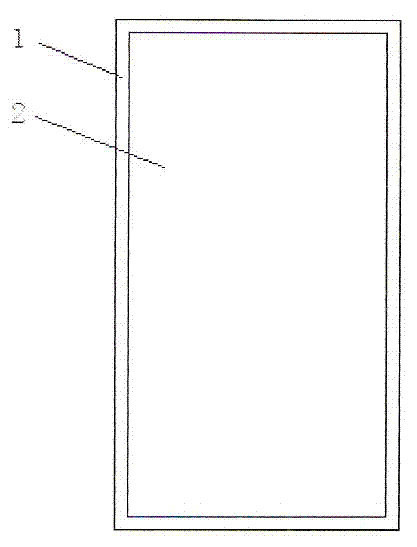

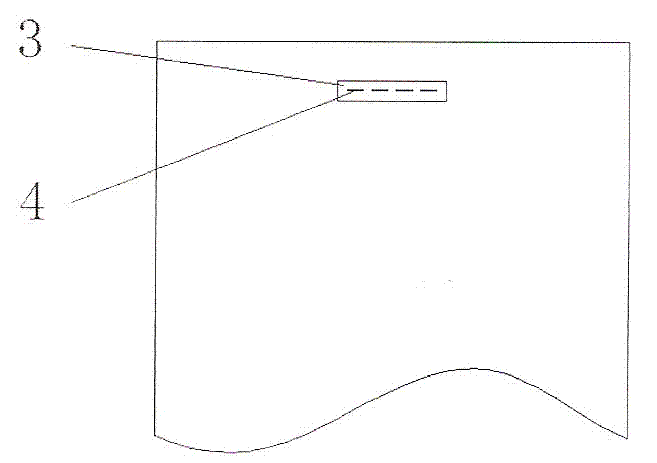

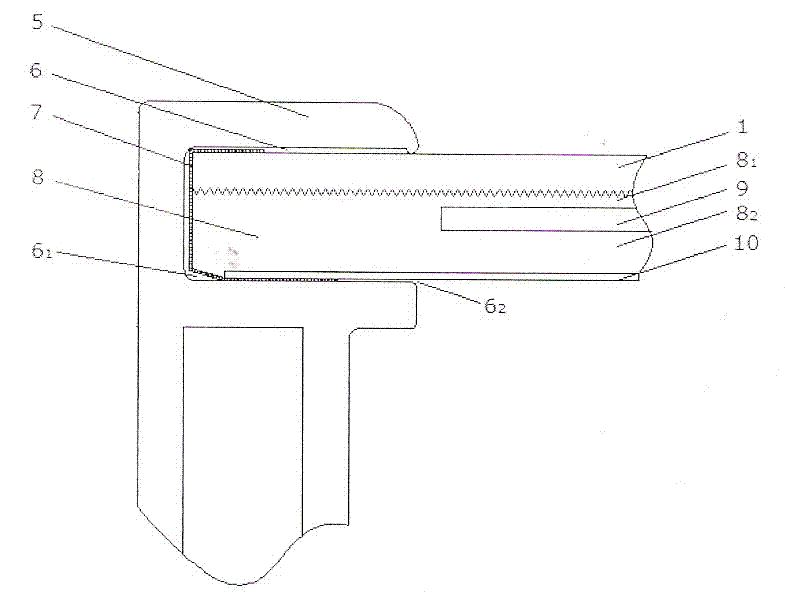

[0022] A method for insulating the aluminum backplane of a photovoltaic module, (such as figure 1 , figure 2 , image 3 shown), including the following steps:

[0023] (1) Cutting the aluminum back plate so that the length and width of the aluminum back plate 2 are both 4-5mm smaller than the length and width of the coated tempered glass 1;

[0024] (2) Opening the electrode lead 4 of the aluminum back plate 2 to make it a square opening 3;

[0025] (3) Typesetting and laying of the components (the order is coated tempered glass 1, EVA81, battery sheet 9, EVA82 and aluminum backplane 10, where EVA81 and EVA82 form the EVA layer 8), and insulate the square opening 3;

[0026] (4) Laminate the laminated layers after layout laying;

[0027] (5) Trimming the laminated parts after lamination;

[0028] (6) Use insulating tape 7 to wrap the trimmed laminate;

[0029] (7) Use filled with silica gel 6 (the figure includes silica gel 6 1 、6 2 ) of the aluminum frame 5 on the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com