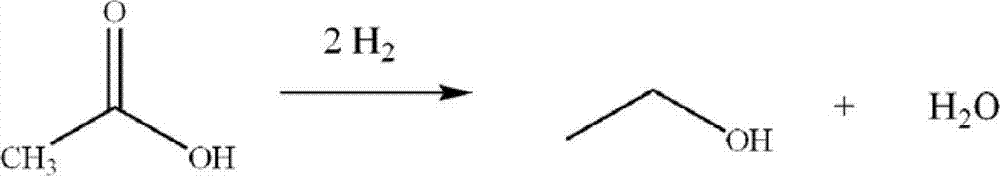

Ethanol production from acetic acid utilizing a molybdenum carbide catalyst

一种碳化钼、助催化剂的技术,应用在有机化学、化学仪器和方法、羟基化合物制备等方向,能够解决没有提供乙酸到乙醇转化的具体实例等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

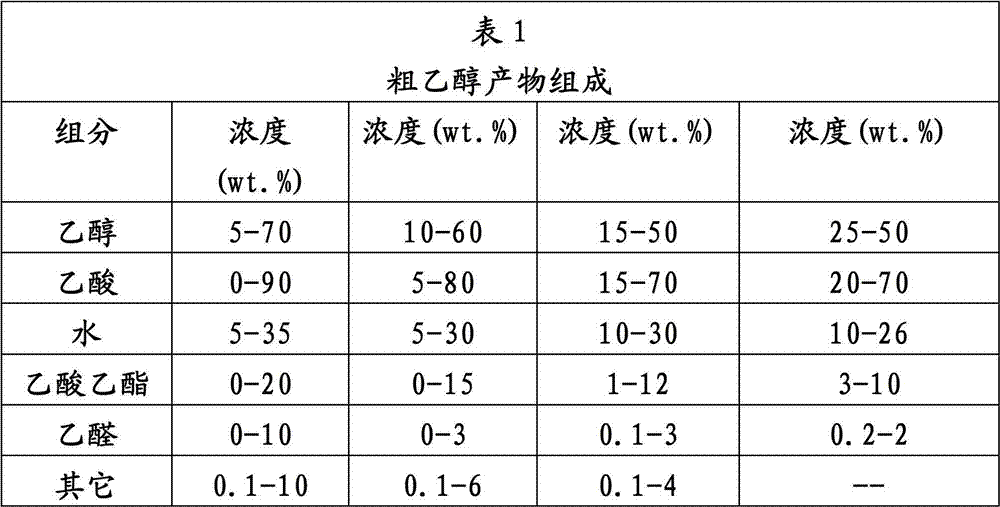

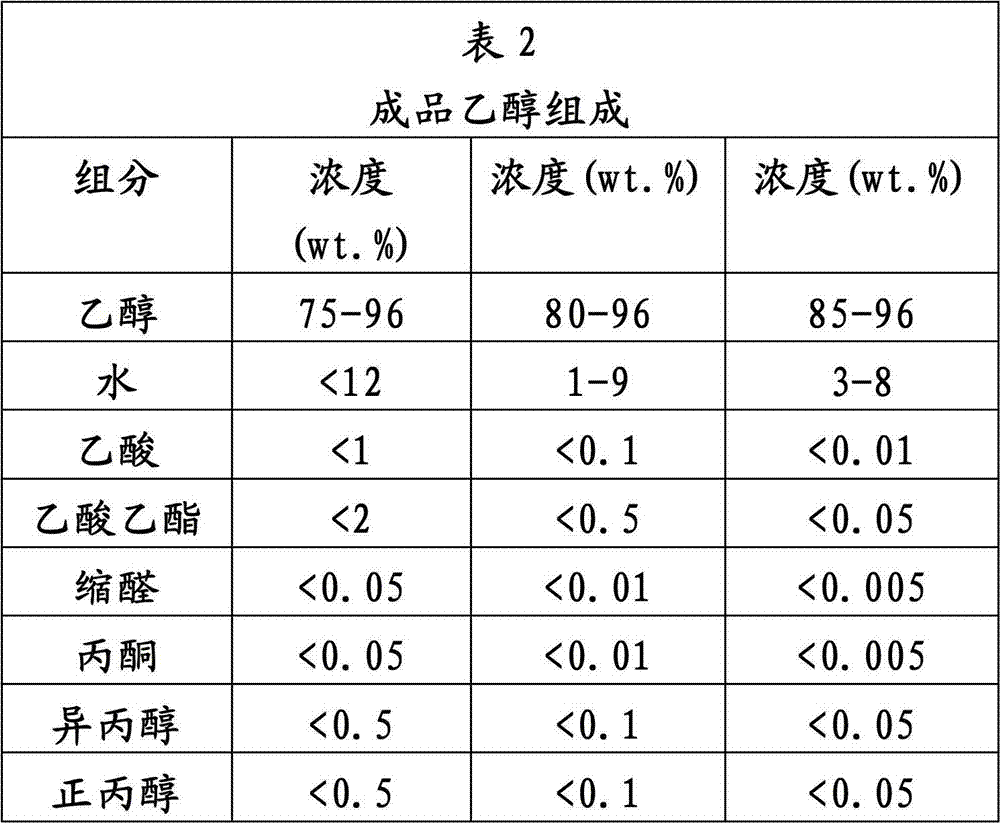

Examples

Embodiment 1

[0060] A catalyst comprising 8 wt.% molybdenum carbide and 5 wt.% copper on silica was deployed in a tubular reactor made of stainless steel with an inner diameter of 30 mm and capable of raising to a controlled temperature. The length of the catalyst bed after loading was about 70 mm.

[0061] The feed liquid of acetic acid was evaporated and charged into the reactor together with hydrogen and helium as carrier gas, and the average gas hourly space velocity ( GHSV) is about 2500hr -1 . The molybdenum carbide and copper catalysts exhibited 98.9% selectivity to ethoxylates. The selectivity to ethane is 1.5%.

Embodiment 2

[0063] The reactor and procedure of Example 1 were repeated except for the catalyst comprising 8 wt.% molybdenum carbide and 1 wt.% palladium on silica.

[0064] The feed liquid of acetic acid was evaporated and charged to the reactor together with hydrogen and helium as carrier gas, the average gas hourly space velocity (GHSV) of the combined gas was about 2500 hr at a temperature of about 250°C and a pressure of 14 barg -1 . The selectivity to ethanol was 64.4% at 52.5% conversion of acetic acid. The selectivity to ethoxylates was 98.3%. The selectivity to ethane was 1.7%.

Embodiment 3

[0066] The reactor and procedure of Example 1 were repeated except for the catalyst comprising 8 wt.% molybdenum carbide and 1 wt.% palladium on silica.

[0067] The feed liquid of acetic acid was evaporated and charged to the reactor together with hydrogen and helium as carrier gas, the average gas hourly space velocity (GHSV) of the combined gas was about 2500 hr at a temperature of about 250°C and a pressure of 14 barg -1 . The selectivity to ethanol was 64.5% at 62% conversion of acetic acid. The selectivity to ethoxylates was 98.3%. The selectivity to ethane was 1.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com