Dissolution tank for drug level benzoic acid production and operation method

A production method and technology of dissolving tank are applied in the field of dissolving tank and water-dissolving method to produce pharmaceutical grade benzoic acid, which can solve the problems of low steam enthalpy, low utilization efficiency, power consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

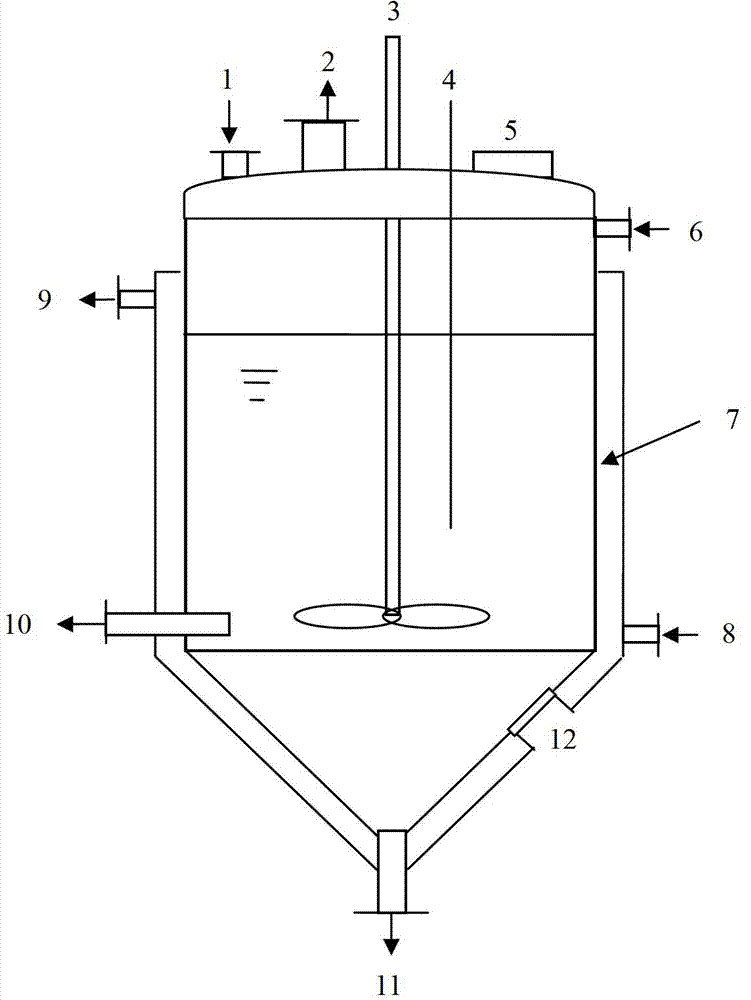

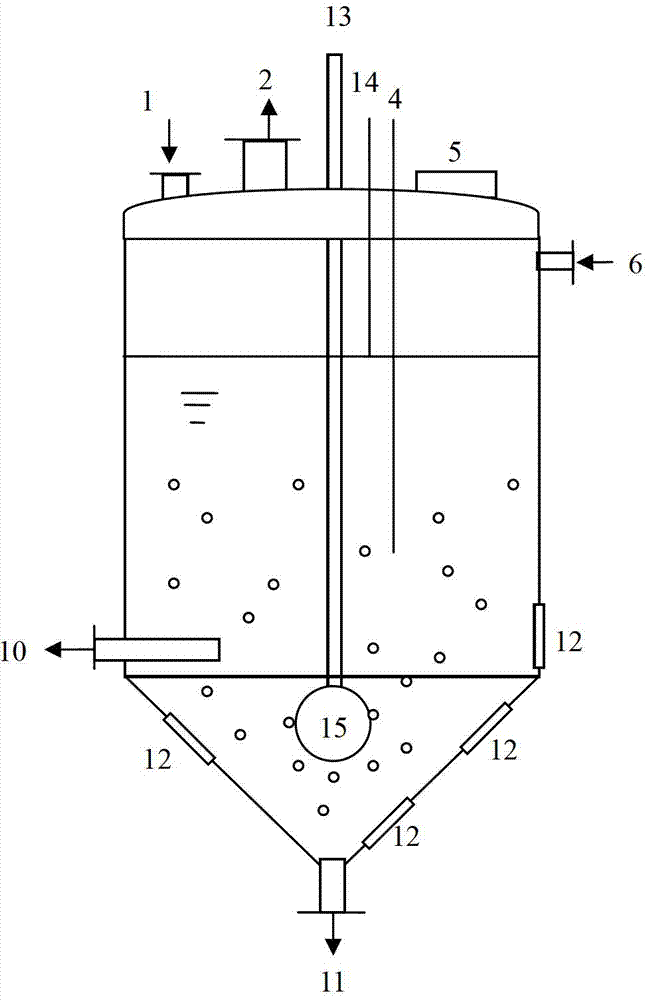

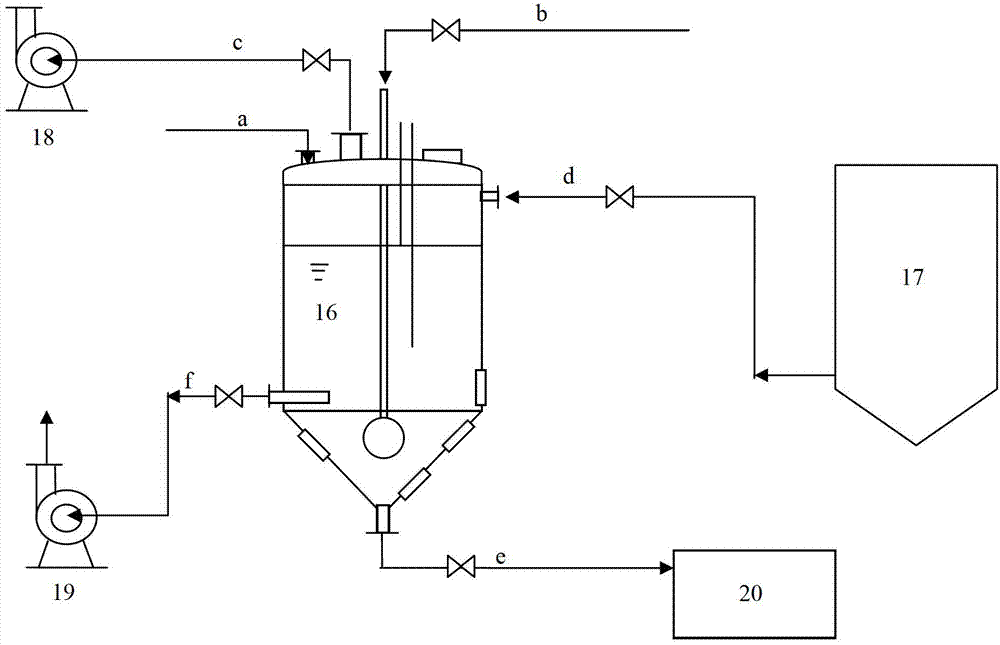

[0028] Embodiment: first put mother liquor into the dissolving tank, automatically control and quantitatively add 4000kg of mother liquor through the liquid level controller, then add 285kg of industrial benzoic acid raw materials, and open the induced draft system at the same time to extract the dust and steam in the tank to prevent the tank from producing positive Then open the steam valve to raise the temperature for 10 minutes. After the temperature rises to 102°C, reduce the steam intake to keep warm and further dissolve the solution. After the dissolution is complete, stop steaming and settle in a static state. After 15 minutes, the impurities naturally settled to the bottom of the dissolution tank under the action of gravity. After the complete settlement was observed through the sight glass, the air induction was stopped, and then the slag discharge port was opened to discharge the impurities to the slag discharge tank, and finally the feeding pump was turned on to trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com