Efficient rolling technology for continuous columnar crystal structure high-aluminum bronze sheet material

A high-alumina bronze and columnar crystal technology, applied in metal rolling and other directions, can solve the problems of losing the excellent performance of continuous columnar crystal structure, poor cold working performance of high-alumina bronze alloy, and recrystallization, etc., and achieves small deformation resistance and high pass quality Large amount of deformation and the effect of preventing the precipitation of brittle phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

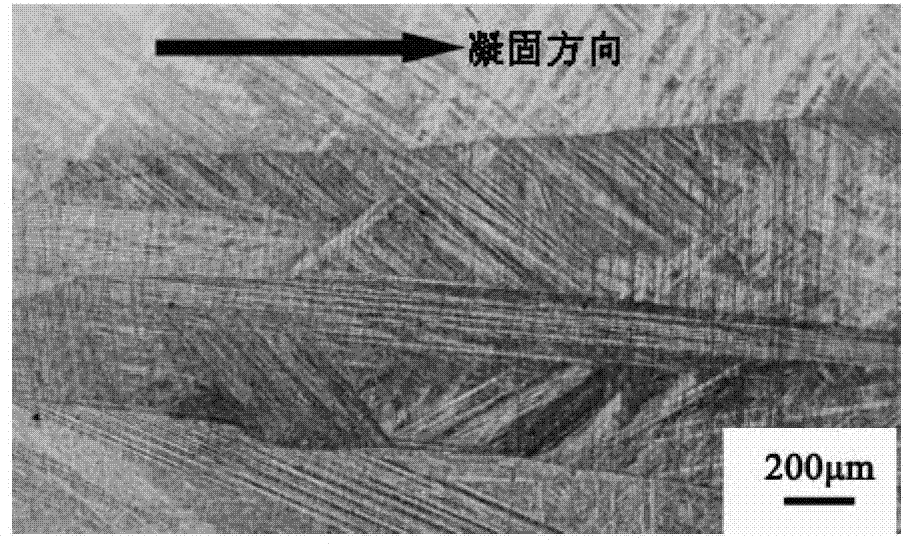

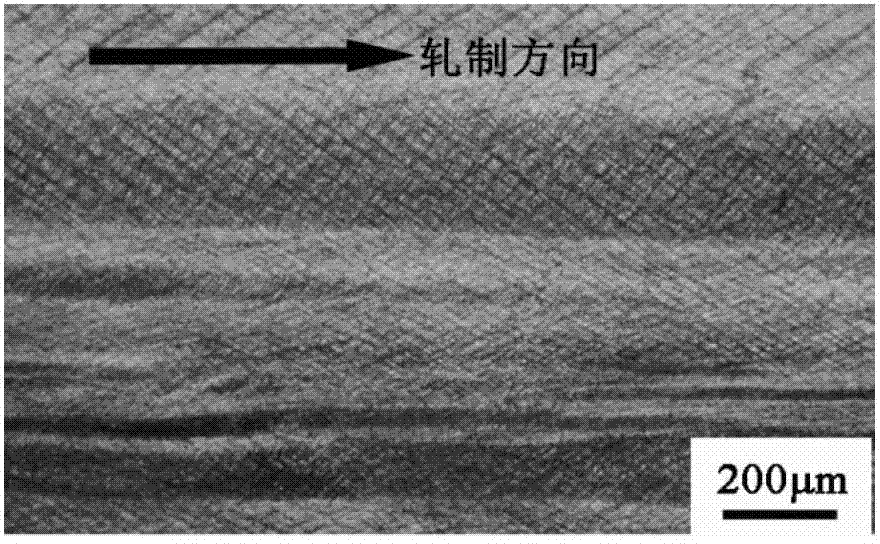

[0017] The Cu-12wt.%Al alloy plate with a width of 25mm, a thickness of 15mm, a bright surface, and a continuous columnar grain structure was prepared by continuous directional solidification; the plate was heated to 850 ° C, kept for 30 minutes, and quickly put into a rolling mill for rolling (The rolling direction is the length direction of the plate, that is, the direction of continuous columnar crystal growth, and the rolling surface is the wide surface of the plate, the same below), and water-cooled rapidly after rolling. After hot rolling, the thickness of the plate is 3mm, and the deformation is 80%. Then carry out 9 passes of warm rolling at a temperature of 400°C, and the reduction of each pass is 5% to 20%. The thickness of the strip after rolling is 0.7mm, and the total processing deformation is 95.3%. The surface of the strip is bright, does not contain brittle precipitates, and has a continuous flaky grain structure.

Embodiment 2

[0019] The Cu-14wt.%Al alloy sheet with a width of 50mm, a thickness of 8mm, a bright surface, and a continuous columnar grain structure was prepared by continuous directional solidification; the sheet was heated to 750°C for 30min and then quickly put into a rolling mill for rolling. Quickly water-cooled after rolling. After hot rolling, the thickness of the strip is 1 mm, and the deformation is 87.5%. Then carry out 7 passes of warm rolling at 375°C, the reduction of each pass is 5% to 20%; the thickness of the strip after rolling is 0.3mm, and the total processing deformation is 96.3%; the surface of the strip is bright and does not contain brittleness. Precipitated phase, with continuous flaky crystal structure.

Embodiment 3

[0021] A Cu-10wt.%Al alloy plate with a width of 100mm, a thickness of 5mm, a bright surface, and a continuous columnar grain structure was prepared by continuous directional solidification; the plate was heated to 800°C for 30min and then quickly put into a two-roll rolling mill for rolling After rolling, it is quickly water-cooled. After hot rolling, the thickness of the strip is 0.5mm, and the deformation is 90%. Then carry out 5 passes of warm rolling at 325°C, the reduction of each pass is 5% to 20%; the strip thickness after rolling is 0.15mm, and the total processing deformation is 97%; the surface of the strip is bright and does not contain brittleness. Precipitated phase, with continuous flaky crystal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com