Ultra-fast preparation method for highly transparent aerogel glass

An aerogel glass, ultra-fast technology, applied in glass production and other directions, can solve the problems of long cycle, high energy consumption and high cost of aerogel glass blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

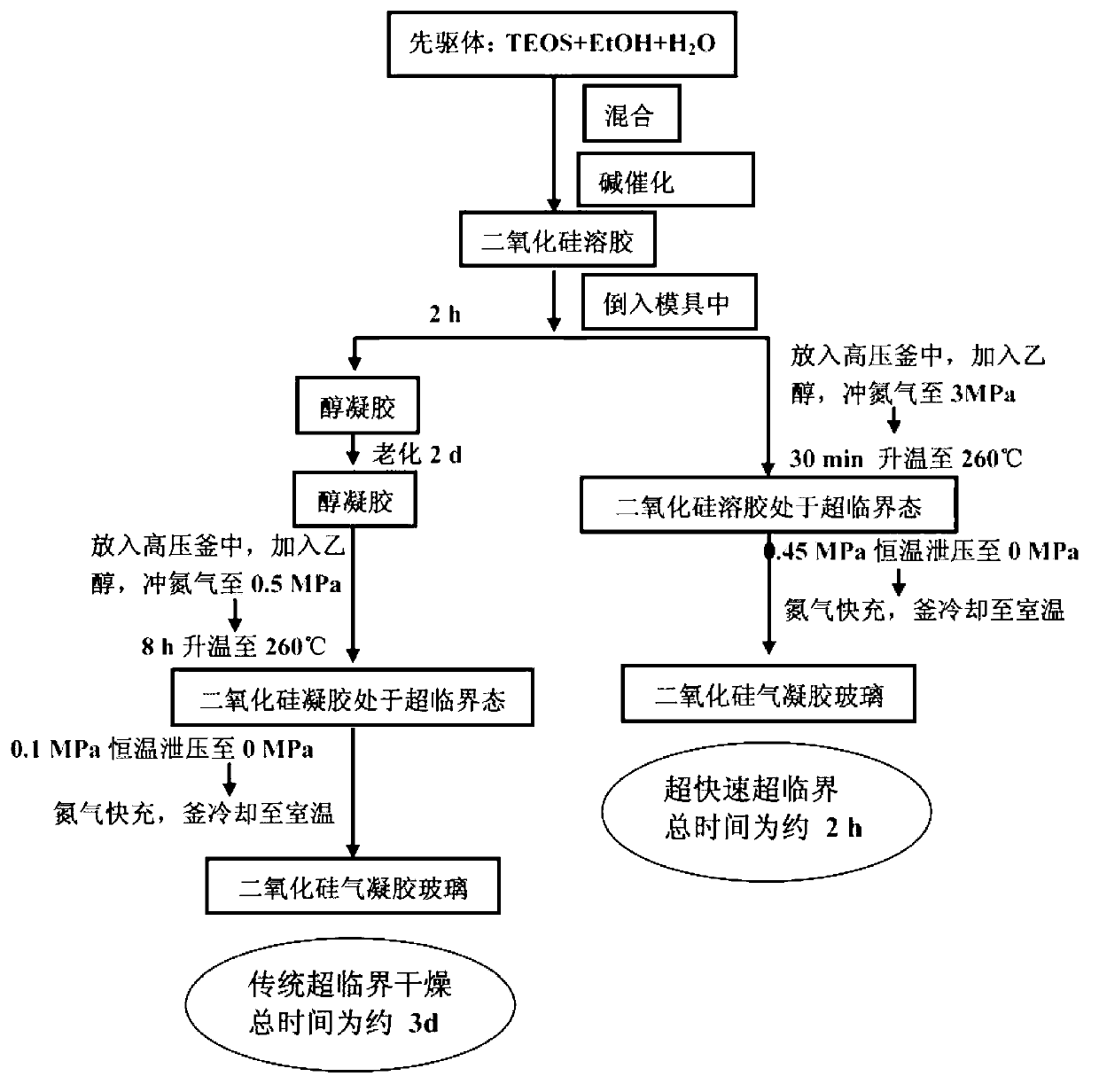

Method used

Image

Examples

Embodiment 1

[0015] With the molar ratio of ethyl orthosilicate: ethanol: distilled water being 1:6:3, take 44ml of ethyl orthosilicate, 72ml of ethanol, and 10.8ml of distilled water, add them to the container in turn, stir for 10min, add 0.03mol / L dilute Ammonia water 15ml, continue to stir for 10min, take out, and pour into the mold.

[0016] Put the mold into the autoclave, add 100ml of ethanol to the autoclave, vacuumize to -0.03MPa, flush nitrogen to 4MPa, heat at a heating rate of 8°C / min for 30min, at this time, the pressure is 12MPa, keep After 10 minutes, quickly release the pressure at a constant temperature at a rate of 0.45MPa / min to 0MPa in the autoclave, then quickly flush with nitrogen at a flow rate of 0.5L / min for 10 minutes, and open the autoclave after cooling to obtain a good formability gas condensation Adhesive glass, the whole process takes 90 minutes, and the glass is round.

Embodiment 2

[0018] With the molar ratio of ethyl orthosilicate: ethanol: distilled water as 1:8:3, take 88ml of ethyl orthosilicate, 192ml of ethanol, and 21.6ml of distilled water, add them to the container in turn, stir for 10min, add 0.03mol / L Dilute ammonia water 30ml, continue to stir for 10 minutes, take it out, and pour it into the mold.

[0019] Put the mold into the autoclave, add 100ml of ethanol to the autoclave, vacuumize to -0.03MPa, flush nitrogen to 3MPa, and heat at a heating rate of 8°C / min for 30min. At this time, the pressure is 15MPa, keep After 10 minutes, quickly release the pressure at a constant temperature of 0.5MPa / min to 0MPa in the autoclave, and then quickly flush it with nitrogen at a flow rate of 0.6L / min for 10 minutes. After cooling, open the autoclave to obtain a good formability. Adhesive glass, the whole process is 90min.

Embodiment 3

[0021] With the molar ratio of ethyl orthosilicate: ethanol: distilled water as 1:12:3, take 44ml of ethyl orthosilicate, 144ml of ethanol, and 14.4ml of distilled water, add them to the container in turn, stir for 10min, add 0.1mol / L Dilute ammonia water 15ml, continue to stir for 10 minutes, take it out, and pour it into the mold.

[0022] Put the mold into the autoclave, add 100ml of ethanol to the autoclave, vacuumize to -0.03MPa, flush nitrogen to 4MPa, heat at a heating rate of 10°C / min for 25min, at this time, the pressure is 13MPa, keep After 10 minutes, quickly release the pressure at a constant temperature at a rate of 0.45MPa / min to 0MPa in the autoclave, then quickly flush with nitrogen at a flow rate of 0.5L / min for 10 minutes, and open the autoclave after cooling to obtain a good formability gas condensation Plexiglas. The whole process is 75min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com