Synthetic method of terpene resin

The technology of a terpene resin and a synthesis method, which is applied in the field of deep processing of chemical resins, can solve the problem of high production cost and achieve the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The synthesis method of the present terpene resin comprises the following steps to synthesize 1 ton of terpene resin: after the catalyst is added into the solvent and mixed uniformly, the raw material is slowly added dropwise under low temperature conditions, where the raw material is heavy turpentine fractionated under vacuum decompression The product contains 65%-70% β-phellandrene, the solvent is toluene, 0.09 tons of anhydrous aluminum trichloride is added to 1.2 tons of toluene and mixed, and then 1.5 tons of 65%-70% content The raw material of β-phellandrene is slowly added dropwise to carry out low-temperature polymerization. The temperature in the reactor is controlled at -15°C ~ -5°C. After 4 hours, it is synthesized by hydrolysis, water washing, and distillation. Solid terpene resin.

Embodiment 2

[0013] The synthesis method of the present terpene resin comprises the following steps to synthesize 1 ton of terpene resin: after the catalyst is added into the solvent and mixed uniformly, the raw material is slowly added dropwise under low temperature conditions, where the raw material is heavy turpentine fractionated under vacuum decompression The product contains 75%-80% β-phellandrene, the solvent is toluene, 0.065 tons of anhydrous aluminum trichloride is added to 1.56 tons of toluene and mixed, and then 1.3 tons of 75%-80% content The raw material of β-phellandrene is slowly added dropwise to carry out low-temperature polymerization. The temperature in the reactor is controlled at -15°C ~ -5°C. After 8 hours, it is synthesized after successively hydrolyzing, washing with water, and distillation. Solid terpene resin.

Embodiment 3

[0015] The synthesis method of this terpene resin comprises the following steps to synthesize 1 ton of terpene resin: After the catalyst is added to the solvent and mixed evenly, the raw material is slowly added dropwise under low temperature conditions, where the raw material is heavy turpentine oil fractionated under reduced pressure in vacuum The product, and containing 75%-80% of β-phellandrene, the solvent is toluene, after adding 0.052 tons of anhydrous aluminum trichloride and 0.013 tons of anhydrous antimony trichloride to 1.33 tons of toluene , then 1.33 tons of β-phellandrene raw materials with a content of 75%-80% are slowly added dropwise to carry out low-temperature polymerization. The temperature in the reactor is controlled at -15°C to -5°C, and after 6 hours , and then sequentially undergo hydrolysis, washing, and distillation to synthesize solid terpene resin.

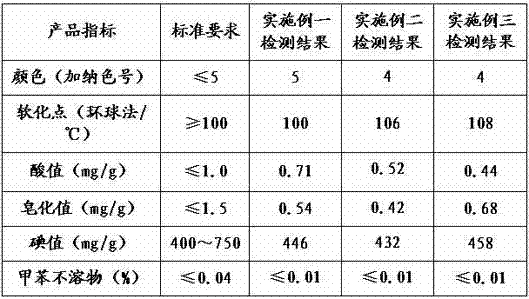

[0016] The detection index of the terpene resin produced in this way is as follows:

[0017]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com