Powdered ore additive

A technology of additives and mineral powder, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of large fluctuations in the quality of mineral powder, small dosage, poor effect, etc., to stimulate the activity of mineral powder, stable product quality, The effect of increasing the activity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: a powder mineral powder additive, the proportion of each component is as follows: (by weight)

[0024] Water-based polymer: 8

[0025] Furfural residue: 26

[0026] Gallic Acid: 1

[0027] Fly Ash: 65

[0028] The preparation process of this powder mineral powder additive is as follows:

[0029] Add fly ash into the mixer, then add furfural slag, gallic acid, and water-based polymer in sequence, and stir for 5 minutes to obtain the mineral powder additive.

example 2

[0030] Example 2: A kind of powder mineral powder additive, each component distribution ratio is as follows: (by weight)

[0031] Water-based polymer: 12

[0032] Furfural residue: 20

[0033] Gallic acid: 0.8

[0034] Fly Ash: 67.2

[0035] The preparation process of this powder mineral powder additive is as follows:

[0036] Add fly ash into the mixer, then add furfural slag, gallic acid, and water-based polymer in sequence, and stir for 5 minutes to obtain the mineral powder additive.

example 3

[0037] Example 3: A kind of powder mineral powder additive, each component distribution ratio is as follows: (by weight)

[0038] Water-based polymer: 20

[0039] Furfural residue: 10

[0040] Gallic acid: 1.5

[0041] Fly Ash: 78

[0042] The preparation process of this powder mineral powder additive is as follows:

[0043] Add fly ash into the mixer, then add furfural slag, gallic acid, and water-based polymer in sequence, and stir for 5 minutes to obtain the mineral powder additive.

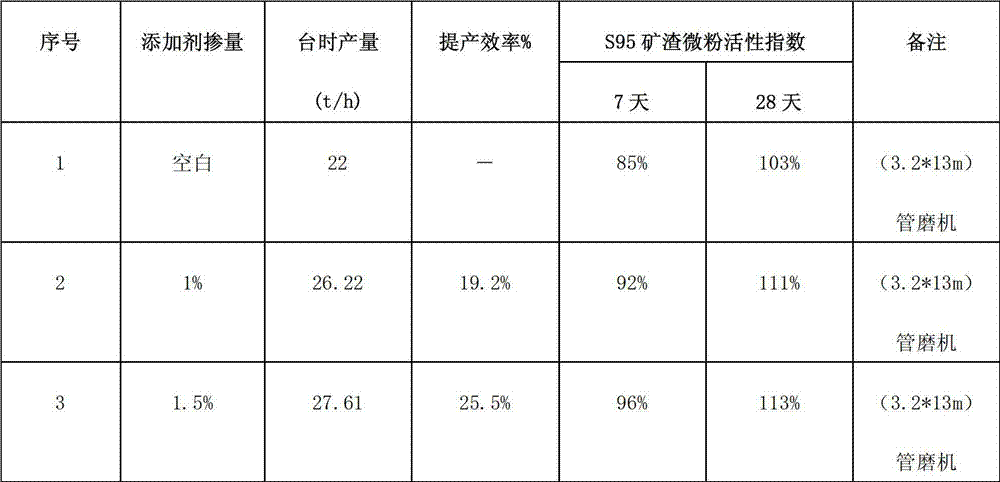

[0044] The effect of powder mineral powder additives is shown in the table below:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com