Novel fuel oil and preparation method thereof

A technology of fuel oil and bio-oil, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., to achieve the effect of convenient preparation, non-volatile and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

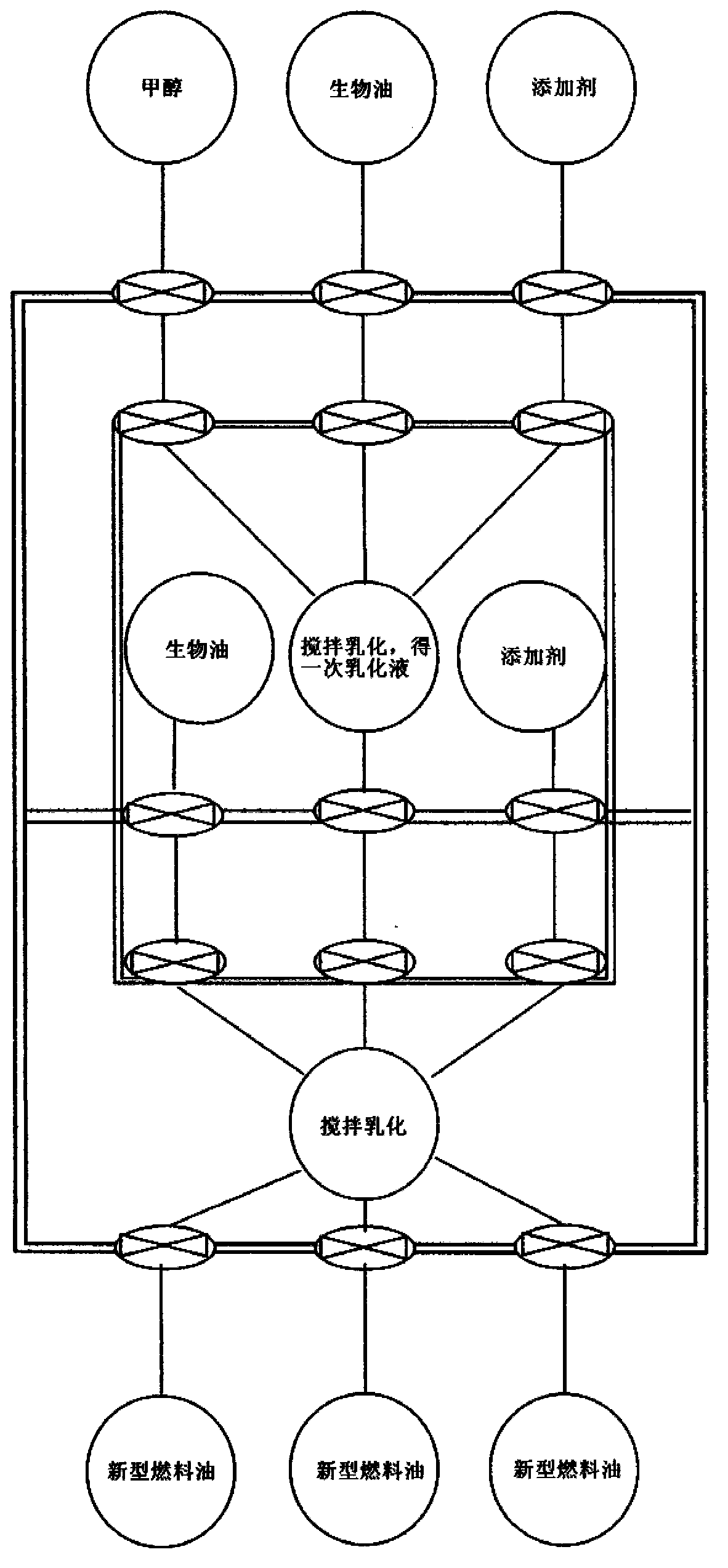

Method used

Image

Examples

Embodiment 1

[0027] A novel fuel oil prepared by the following method:

[0028] (1) Mix the following components by weight: 75 parts of methanol, 18 parts of bio-oil, 7 parts of additives, stir to emulsify, and obtain a primary emulsion;

[0029] (2) Take 89 parts of the primary emulsion obtained in step (1), then add 6 parts of bio-oil and 5 parts of additives, stir to emulsify, and obtain the secondary emulsion, which is a new type of fuel oil;

[0030] The additives in the step (1) and step (2) are composed of the following components by mass ratio: antiknock compound 20%, stabilizer 30%, mutual solvent 50%; the antiknock compound is isooctane, the The stabilizer is 2,6-di-tert-butyl-4-methylphenol (BHT), and the mutual solvent is ferrocene.

Embodiment 2

[0032] A novel fuel oil prepared by the following method:

[0033] (1) Mix the following components by weight: 78 parts of methanol, 12 parts of bio-oil, and 10 parts of additives, stir to emulsify, and obtain a primary emulsion;

[0034] (2) Take 90 parts of the primary emulsion obtained in step (1), then add 6 parts of bio-oil and 4 parts of additives, stir to emulsify, and obtain a secondary emulsion;

[0035] (3) adding water with a weight of 2‰ to the secondary emulsion obtained in step (2), and stirring evenly to obtain novel fuel oil;

[0036] The additives in the step (1) and step (2) are composed of the following mass ratio components: 20% antiknock compound, 30% stabilizer, 50% mutual solvent; the antiknock compound is cumene, the Butylated hydroxyanisole (BHA) is used as the stabilizer, and isooctyl alcohol is used as the mutual solvent.

Embodiment 3

[0038] A novel fuel oil prepared by the following method:

[0039] (1) Mix the following components by weight: 80 parts of methanol, 17 parts of bio-oil, and 3 parts of additives, stir to emulsify, and obtain a primary emulsion;

[0040](2) Take 94 parts of the primary emulsion obtained in step (1), then add 3 parts of bio-oil and 3 parts of additives, stir to emulsify, and obtain a secondary emulsion;

[0041] (3) adding water with a weight of 3‰ to the secondary emulsion obtained in step (2), and stirring evenly to obtain novel fuel oil;

[0042] The additives in the step (1) and step (2) are composed of the following mass ratio components: 20% antiknock compound, 30% stabilizer, 50% mutual solvent; the antiknock compound uses methylcyclopentadiene Manganese tricarbonyl (MMT), the stabilizer uses butyl hydroxyanisole (BHA), and the mutual solvent uses ferrocene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com