Spiral bevel gear size silvering method

A technology of spiral bevel gears and dimensions, which is applied in the direction of cells, electrolytic processes, electrolytic components, etc., can solve problems such as non-conforming silver layers and falling off of silver layers, and achieve mature process methods, stable product quality, and reasonable and accurate process parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

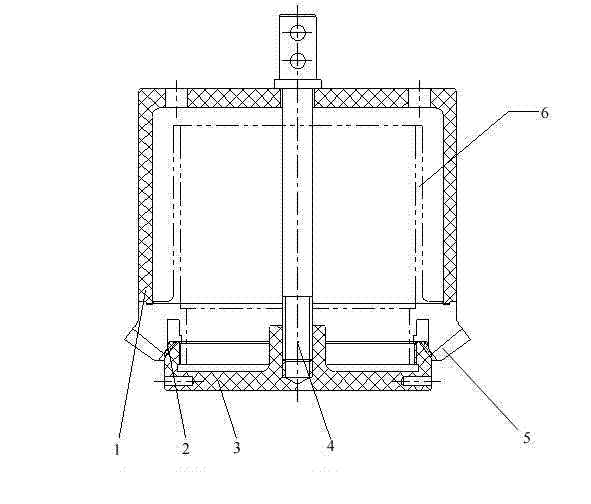

[0020] The spiral bevel gear made of 40CrNiMoA is silver-plated, and the clamping schematic diagram during the silver-plating process of the spiral bevel gear is as follows figure 1 As shown, the polyvinyl chloride protective sleeve is used to protect the parts that do not need to be silver-plated, so that the silver-plated parts are immersed in the silver-plating bath.

[0021] A method of silver-plating the size of a spiral bevel gear is carried out according to the following steps:

[0022] (1) Degreasing, using lye to degrease the spiral bevel gear parts, the composition of lye is: NaOH 40g / l, NaOH 3 PO 4 .12H 2 O 30 g / l, Na 2 SiO 3 10,Na 2 CO 3 50 g / l, the temperature of the bath solution is 60°C, the time is 20 minutes, then rinse with hot water, and rinse with cold water;

[0023] (2) Weak corrosion. Weakly corrode the parts after degreasing with rhodinic hydrochloride solution, pure HCL100g / l in rhodinic hydrochloric acid solution; rhodinic acid 2 g / l, bath te...

Embodiment 2

[0030] The spiral bevel gear made of 40CrNiMoA is silver-plated, and the clamping schematic diagram during the silver-plating process of the spiral bevel gear is as follows figure 1 As shown, the polyvinyl chloride protective sleeve is used to protect the parts that do not need to be silver-plated, so that the silver-plated parts are immersed in the silver-plating bath.

[0031] A method of silver-plating the size of a spiral bevel gear is carried out according to the following steps:

[0032] (1) Degreasing, using lye to degrease the spiral bevel gear parts, the composition of lye is: NaOH 75g / l, NaOH 3 PO 4 .12H 2O 20g / l, Na 2 SiO 3 3g / l, Na 2 CO 3 100 g / l, the temperature of the bath solution is 70°C, the time is 18 minutes, then rinse with hot water, then rinse with cold water;

[0033] (2) Weak corrosion. Weakly corrode the parts after degreasing with rhodine hydrochloride solution. The pure HCL in the rhodine hydrochloride solution is 120 g / l; rhodine 1.5 g / l, t...

Embodiment 3

[0040] The spiral bevel gear made of 40CrNiMoA is silver-plated, and the clamping schematic diagram during the silver-plating process of the spiral bevel gear is as follows figure 1 As shown, the polyvinyl chloride protective sleeve is used to protect the parts that do not need to be silver-plated, so that the silver-plated parts are immersed in the silver-plating bath.

[0041] A method of silver-plating the size of a spiral bevel gear is carried out according to the following steps:

[0042] (1) Degreasing, using lye to degrease the spiral bevel gear parts, the composition of lye is: NaOH 60g / l, NaOH 3 PO 4 .12H 2 O10 g / l, Na 2 SiO 3 8g / l, Na 2 CO 3 30g / l, bath temperature 80°C, time 15min, then rinse with hot water, then rinse with cold water;

[0043] (2) Weak corrosion. Weakly corrode the parts after degreasing with rhodine hydrochloride solution. The pure HCL in the rhodine hydrochloride solution is 150 g / l; rhodine 1g / l, the bath temperature is room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com