750kv composite material cross arm

A composite material and composite material pipe technology, which is applied in building types, buildings, towers, etc., can solve the problems of difficult to meet the requirements of large loads, restrict the application of composite materials, and difficult to research, so as to solve the wind deviation and pollution flashover accidents. , Improve the level of safe operation, the effect of less possibility of theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

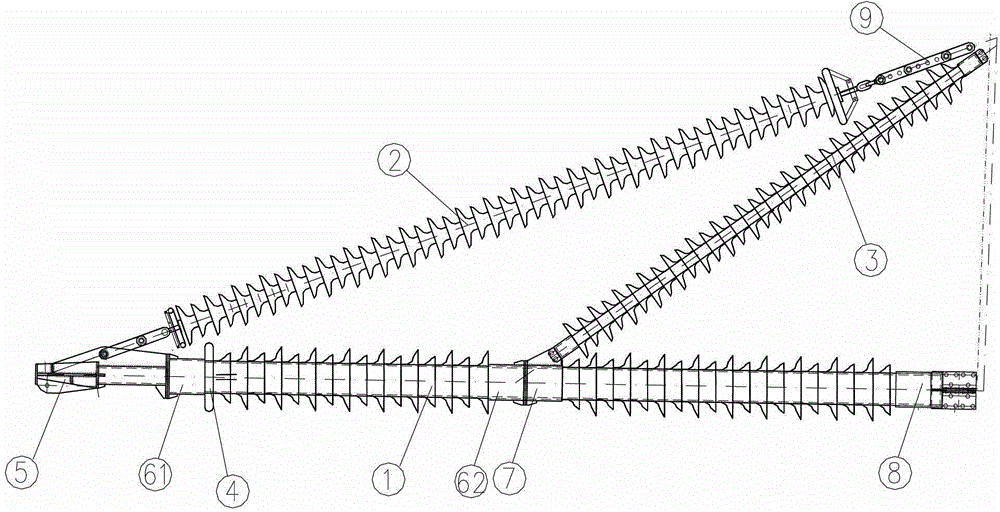

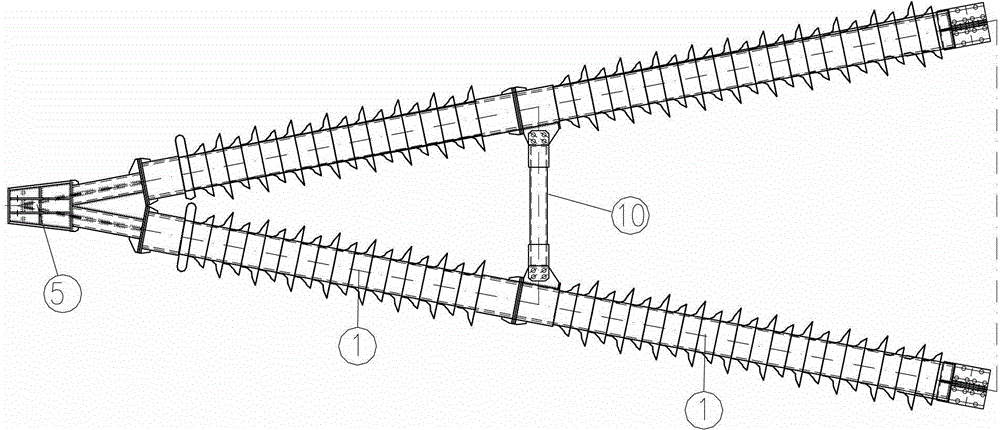

[0026] Such as Figure 1~Figure 2 As shown, a 750kV composite material cross arm of the present invention includes a composite material tubular main material 1, two composite material insulator strings 2, two composite material diagonal braces 3, a composite material horizontal support rod 10 and a steel hanger Click Device 5.

[0027] Composite material tube-shaped main material 1 includes two kinds of first composite material tube-shaped main material and second composite material tube-shaped main material; the first composite material tube-shaped main material includes a first composite material component, and the two ends The first steel casing 61 and the second steel casing 62 are respectively provided; the second composite material pipe-shaped main material includes a second composite material component, and a steel casing node 7 is provided at one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com