Optical detection probe with automatic positioning function for high-temperature melt components

An automatic positioning and optical detection technology, which is applied in the optical detection probe of molten liquid composition and on-line detection of high-temperature melt composition, to reduce liquid level fluctuations and improve measurement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

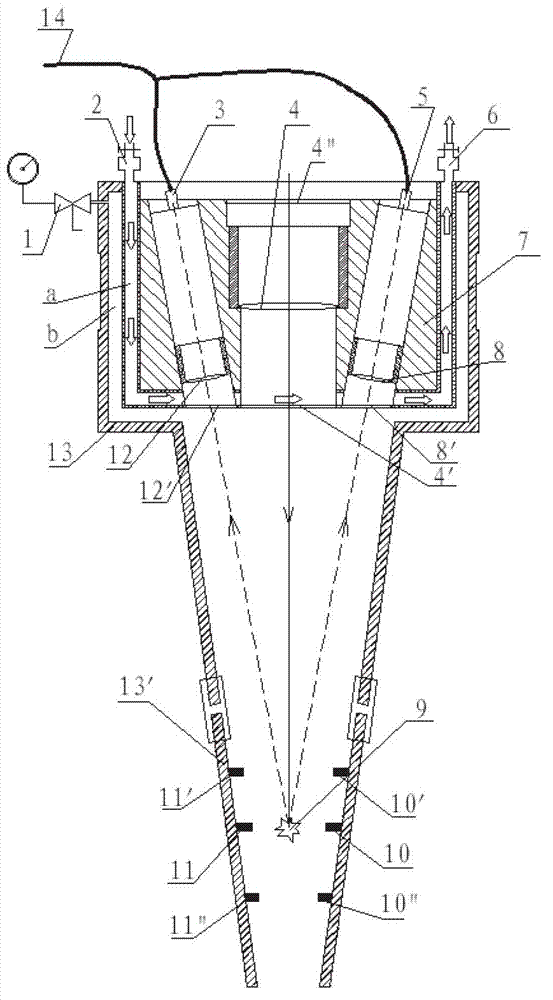

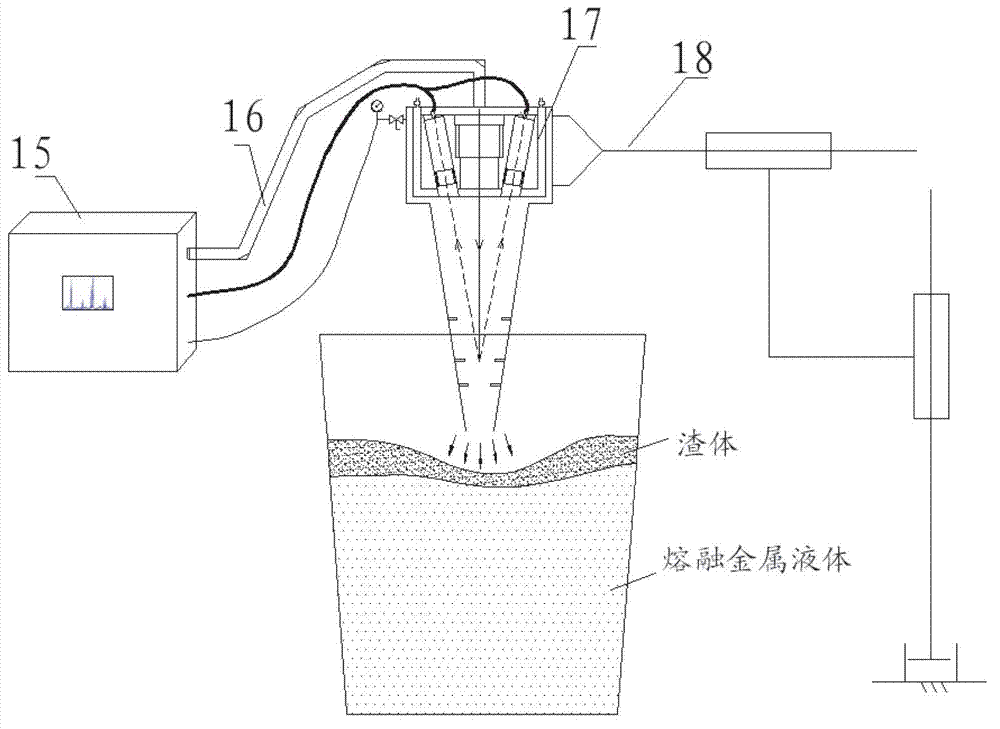

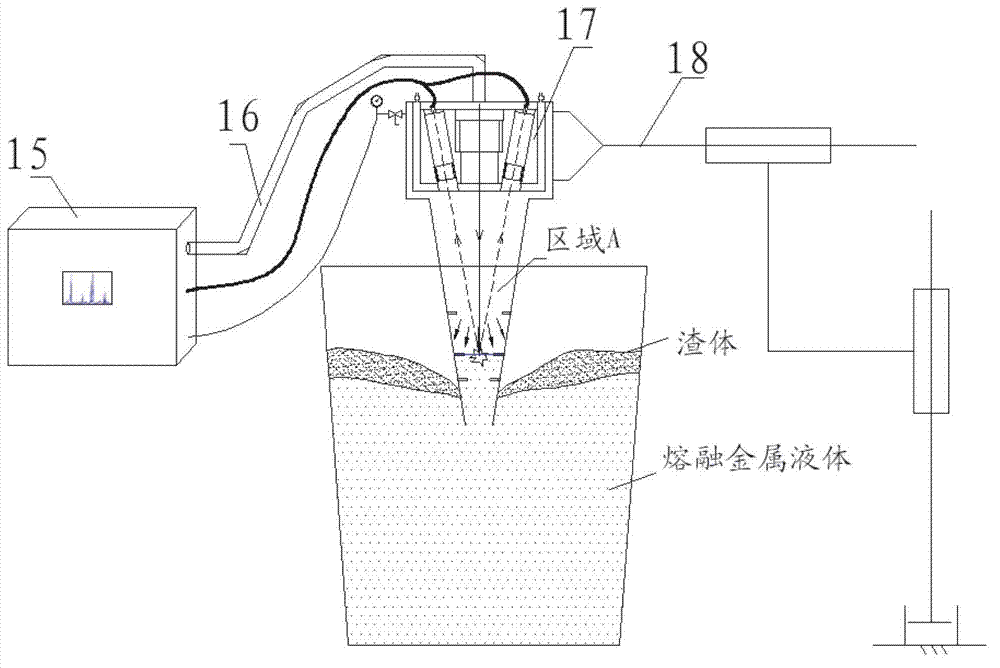

[0021] Such as figure 1 As shown, a molten liquid component optical detection probe with automatic positioning function is composed of a probe body 7 and a high temperature resistant shell 13 . The inside of the probe body 7 is fixed with an incident laser focusing lens 4, spectral signal focusing lenses 8 and 12, and conductive fiber joints 3 and 5, and transparent windows are respectively opened at positions corresponding to the incident laser focusing lens 4 and spectral signal collecting lenses 8 and 12 4', 12', 8', the incident laser focusing lens 4 is provided with a transparent window 4" for the incident laser pulse, and the window joints are designed as a sealed structure. The two bundles of optical fibers corresponding to the conductive fiber joints 3 and 5 are finally coupled to Conductive fiber 14.

[0022] The high-temperature-resistant shell 13 is designed as a separate structure, and the lower end is a detachable conical tubular structure 13', which is immersed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com