Water-in-oil emulsion composition

An emulsified composition, water-in-oil type technology, applied in the direction of food science, edible oil/fat, edible oil/fat, etc., can solve the problems of deterioration of physical properties, dryness, and inability to obtain sufficient emulsification stability, etc., to achieve excellent flavor , little change over time, excellent emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

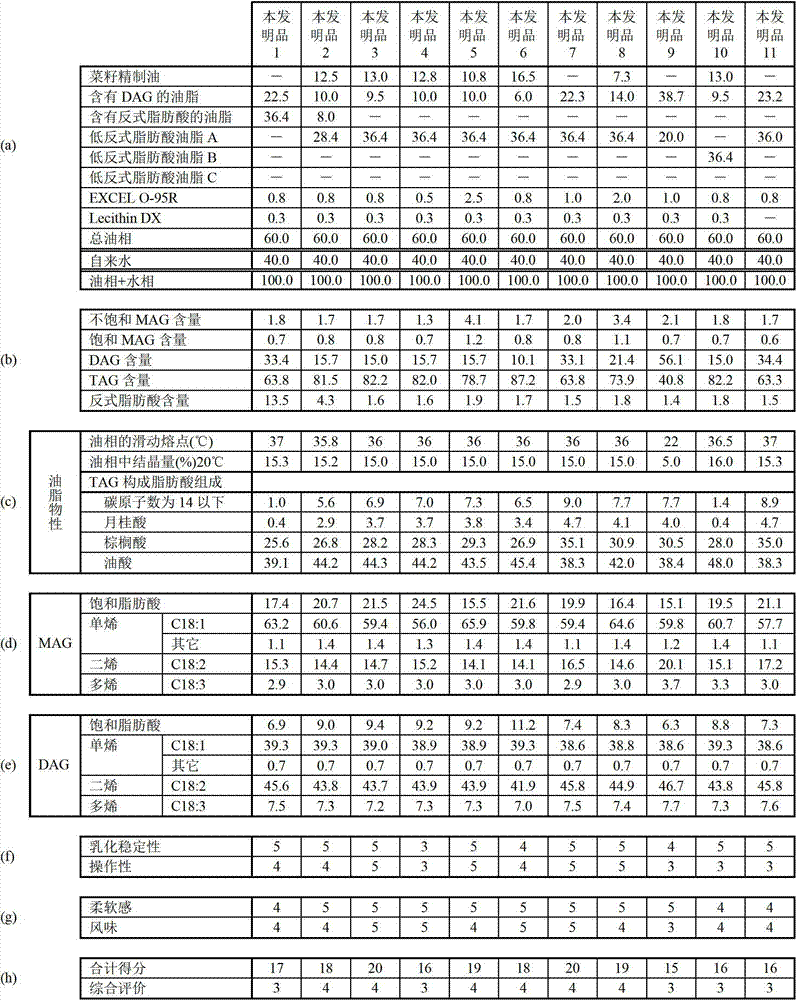

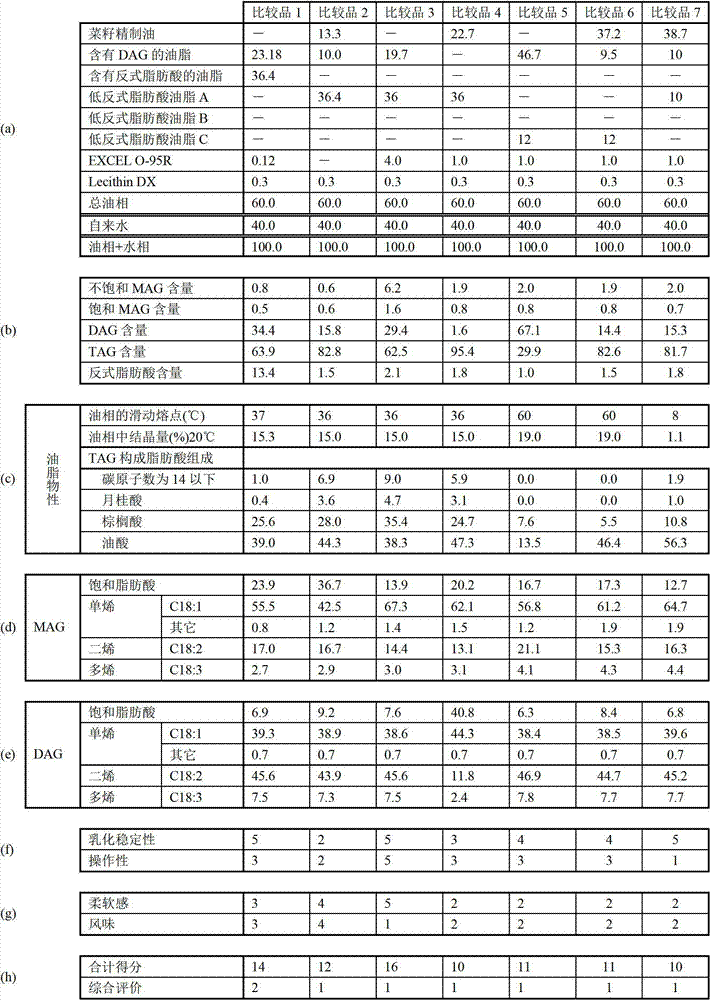

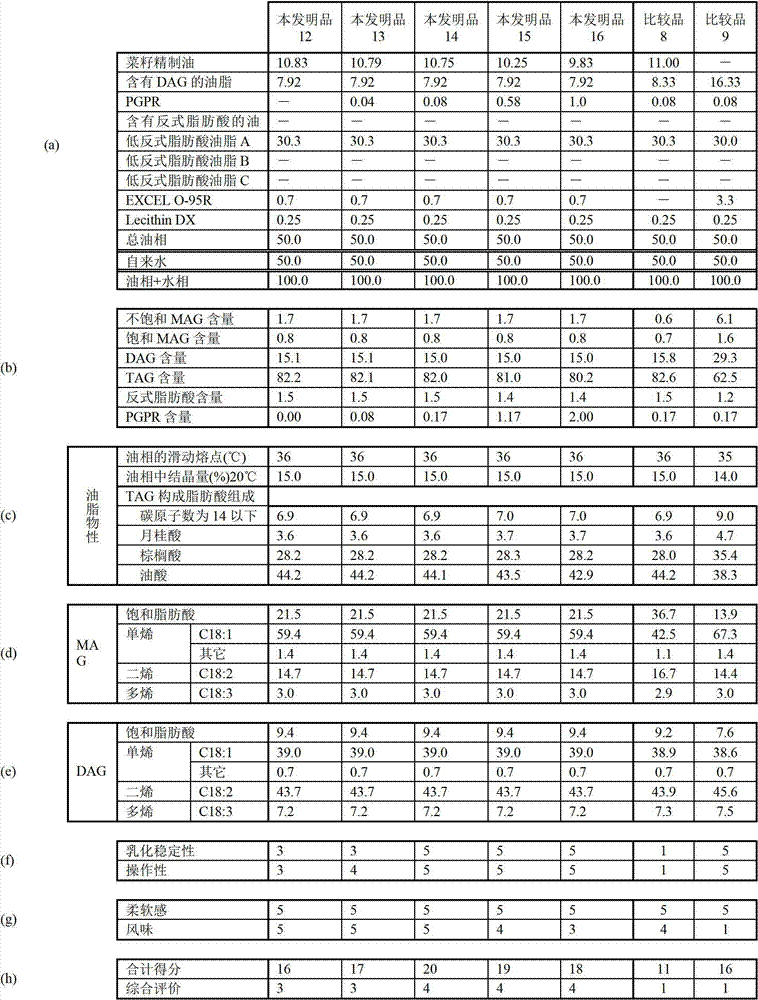

[0062] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto.

[0063] In addition, in the following examples, TAG means triacylglycerol, DAG means diacylglycerol, and MAG means monoacylglycerol.

[0064] [Analytical method]

[0065] Composition of acylglycerols:

[0066] About 10 mg of a fat sample and 0.5 mL of a trimethylsilylating agent ("silylating agent TH", manufactured by Kanto Chemical Co., Ltd.) were added to a glass sample bottle, sealed, and heated at 70° C. for 15 minutes. 1.0 mL of water and 1.5 mL of hexane were added thereto and shaken. After standing still, the upper layer was subjected to gas chromatography (GLC) and analyzed.

[0067] Composition of fatty acids:

[0068]Fatty acid methyl esters were prepared according to the "01 preparation method of fatty acid methyl esters (2.4.1.-1996)" in the "Basic oil analysis test method" edited by the Japanese Oil Chemists' Society,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com