Riveting point device with double air cylinders

A dual-cylinder and riveting point technology, applied in the field of automation equipment, can solve the problems of easy wear, high cost, difficult machining accuracy, etc., and achieve the effects of high operating frequency, low cost, and fewer parts involved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

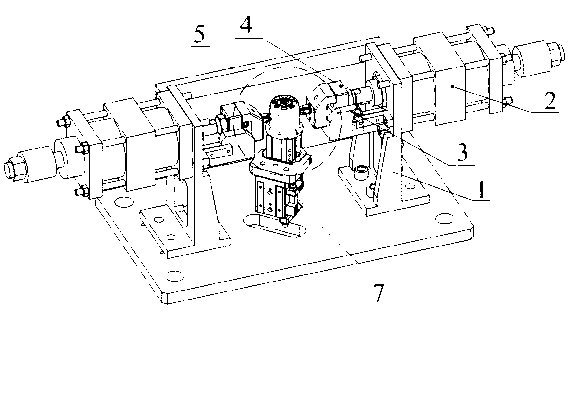

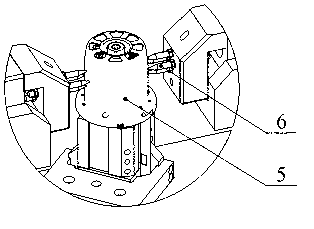

[0017] Such as figure 1 As shown, the double-cylinder riveting device includes a carrier 7 for carrying fixed products and supports 1 on both sides of the carrier. A series cylinder 2 is installed on each support 1, and the two series cylinders face each other. There is an L-shaped block 3 on the bracket 1, and a slider 4 is arranged on the L-shaped block 3. The material of the slider 4 and the L-shaped block 3 is tungsten steel, and the piston rod of the cylinder 2 and the slider 4 are driven in series. Connected, the serial cylinder drives the slider 4 to move along the L-shaped block 3, such as figure 2 As shown, each slider 4 is provided with four rivets 6 , and the rivets 6 are opposite to the products 5 on the stage 7 .

[0018] The device is suitable for the assembly station of the motor stator and the shell, and the function of the riveting point is to prevent the relative movement of the stator and the shell.

[0019] The tandem cylinders 2 arranged on the left and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com