Method for preparing silver/carbon composite nanoring structure by laser

A carbon composite and nano-ring technology is applied in the field of preparing silver/carbon composite nano-rings to achieve the effect of widening the field and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare a 0.5mM silver nitrate ethanol solution in the dark, the purpose of which is to prevent the silver nitrate from being decomposed by light. The configured silver nitrate ethanol solution can be completely dissolved by ultrasonication in an ice bath. The purpose of the ice bath is to prevent the temperature from being too high during ultrasonication, and the silver nitrate will be decomposed by heat.

[0022] Pipette 3ml of the prepared silver nitrate ethanol solution into a quartz tube that does not absorb laser light, move the quartz tube to the laser light path, so that the parallel light spot of the millisecond pulse laser completely covers the entire solution from above the solution, and the nanosecond pulse laser The parallel light spot and the millisecond pulse laser spot are 90°, facing the middle part of the solution;

[0023] The 1064nm millisecond pulse laser and the 1064nm nanosecond pulse laser are connected by a linkage device, so that the light emit...

Embodiment 2

[0027] Implementation process is the same as embodiment 1;

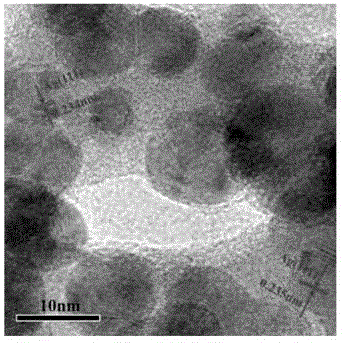

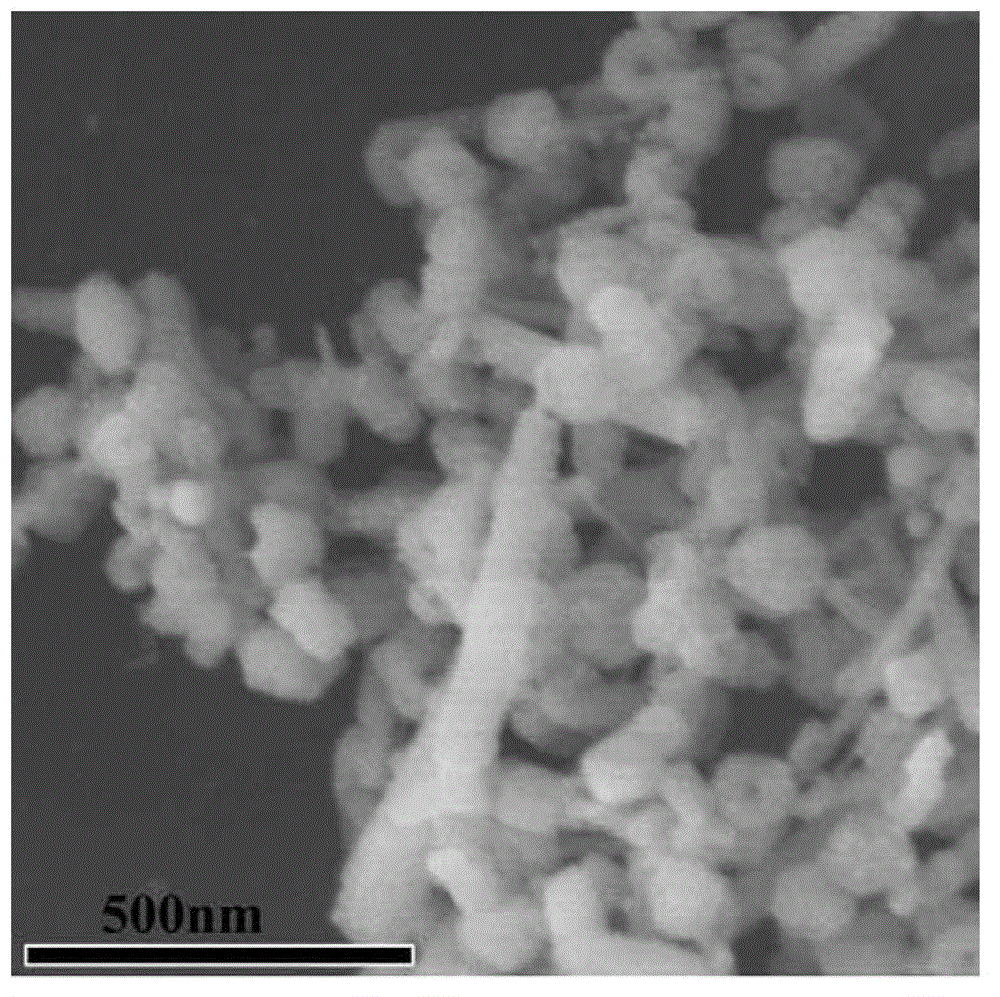

[0028] The laser parameters of the millisecond pulse laser are 130A, 6ms, 1Hz, and the single pulse energy is 7.36J; the laser parameters of the nanosecond pulse laser are 650V, 1Hz, and the single pulse energy is 303mJ. After 5 minutes, the dispersed silver / carbon composite nanorings with neat edges were obtained.

Embodiment 3

[0030] Implementation process is the same as embodiment 1;

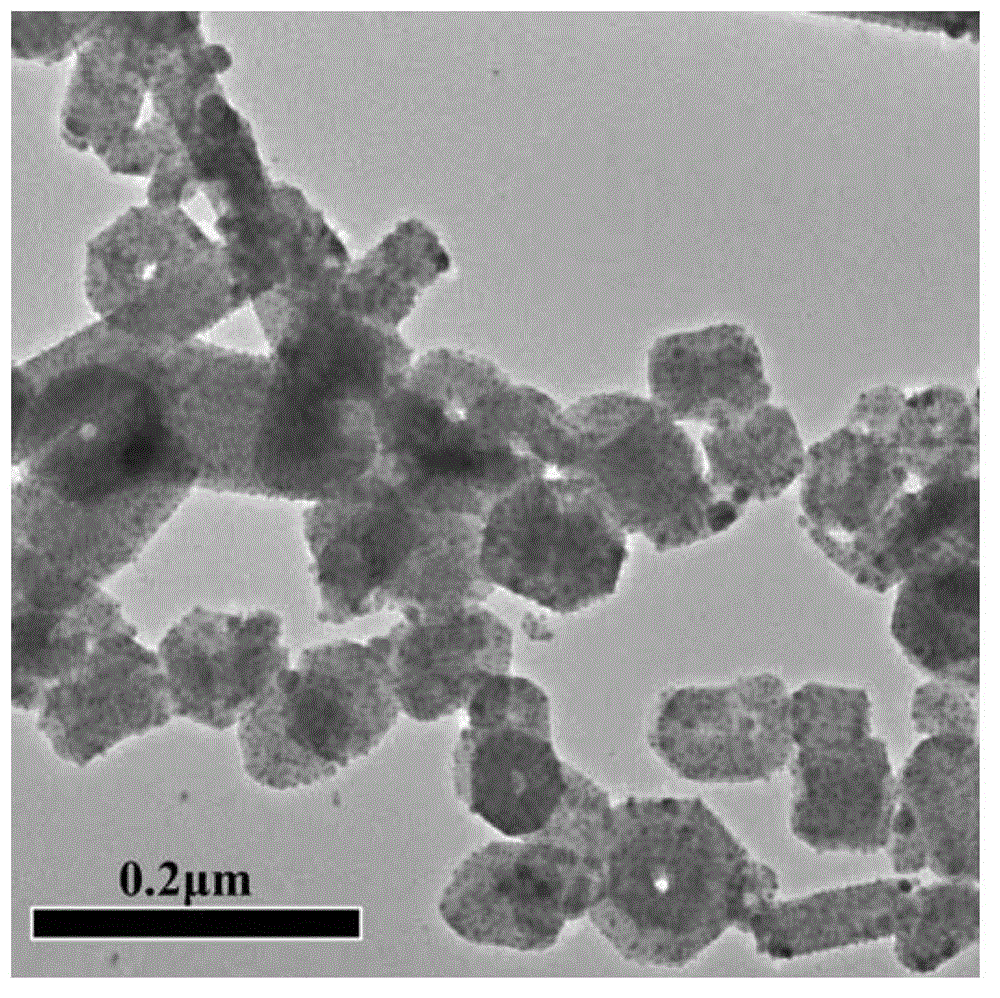

[0031] The laser parameters of the millisecond pulse laser are set to 130A, 6ms, 1Hz, and the single pulse energy is 7.36J; the laser parameters of the nanosecond pulse laser are 650V, 1Hz, and the single pulse energy is 303mJ. After irradiating the solution for 0.5 min, neatly dispersed silver / carbon composite nanorings were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com