Purification method of protein group of 30 kD in silkworm pupa

A purification method and silkworm chrysalis technology, applied in the field of protein purification, can solve the problems of high cost, low purification efficiency, complicated and cumbersome purification steps for 30kD protein groups, etc., and achieve the effects of reducing damage and loss and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

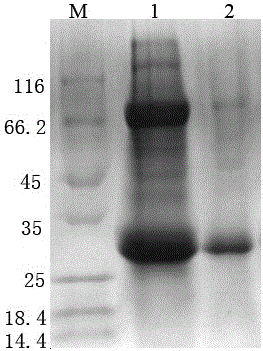

Embodiment 1

[0023] PBS formulation: 137mM NaCl, 2.7mM KCl, 10mM NaCl 2 HPO 4 , 2mM KH 2 PO 4 , pH7.4~7.6.

[0024] 1. Homogenization and centrifugation

[0025] Take 100g silkworm chrysalis and homogenize with 1000mL pre-cooled PBS; centrifuge the homogenate at 0~2℃, 12000rpm for 30min, and collect the supernatant.

[0026] 2. Fractional precipitation of ammonium sulfate

[0027] (1) Make the supernatant to volume, according to the ammonium sulfate saturation calculator, add a certain amount of solid (NH 4 ) 2 SO 4 , to solution (NH 4 ) 2 SO 4 The saturation is 25%, stirred on a magnetic stirrer at 4°C for 30 minutes, and then rested at 4°C for 90 minutes. Centrifuge at 12000 rpm for 30 min at 4°C and collect the supernatant.

[0028] (2) Make the supernatant to volume, according to the ammonium sulfate saturation calculator, weigh a certain amount of solid (NH 4 ) 2 SO 4 , to solution (NH 4 ) 2 SO 4 The saturation is 65%, stirred on a magnetic stirrer at 4°C for 30 minu...

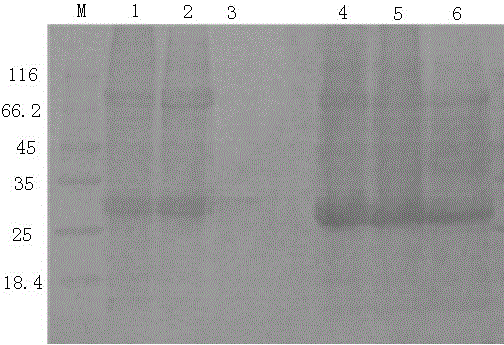

Embodiment 2

[0033] The present embodiment sets three different ammonium sulfate salting-out saturations and carries out three groups of comparison experiments, and each group of experiments carries out the following operations respectively:

[0034] PBS formulation: 137mM NaCl, 2.7mM KCl, 10mM NaCl 2 HPO 4 , 2mM KH 2 PO 4 , pH7.4~7.6.

[0035] 1. Homogenization and centrifugation

[0036] Take 100g of silkworm chrysalis freeze-dried powder (provided by Zhejiang Zhongqi Biomedical Co., Ltd.), and 1000mL pre-cooled PBS homogenate; the homogenate is centrifuged at 0~2°C, 12000rpm for 30min, and the supernatant is collected.

[0037]2. Fractional precipitation of ammonium sulfate

[0038] (1) Make the supernatant to volume, according to the ammonium sulfate saturation calculator, add a certain amount of solid (NH 4 ) 2 SO 4 , to solution (NH 4 ) 2 SO 4 The saturation is 25%, stirred on a magnetic stirrer at 4°C for 30 minutes, and then rested at 4°C for 90 minutes. Centrifuge at 1...

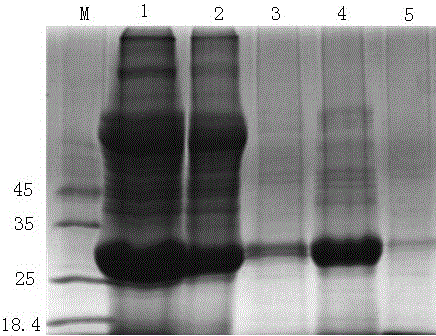

Embodiment 3

[0044] PBS formulation: 137mM NaCl, 2.7mM KCl, 10mM NaCl 2 HPO 4 , 2mM KH 2 PO 4 , pH7.4~7.6.

[0045] 1. Homogenization and centrifugation

[0046] Take 100g silkworm chrysalis freeze-dried powder (provided by Zhejiang Zhongqi Bio-Pharmaceutical Co., Ltd.), 1000mL pre-cooled (refrigerated at 4°C) PBS homogenate three times, each time for 1min, and the middle homogenate cup was cooled on ice for 1min; Centrifuge at 8000 rpm for 30 min, filter the supernatant with 9 layers of gauze, repeat three times, and collect the supernatant.

[0047] 2. Fractional precipitation of ammonium sulfate

[0048] (1) Make the supernatant to volume, according to the ammonium sulfate saturation calculator, add a certain amount of solid (NH 4 ) 2 SO 4 , to solution (NH 4 ) 2 SO 4 The saturation is 25%, stirred on a magnetic stirrer at 4°C for 30 minutes, and then rested at 4°C for 90 minutes. 4°C, 8000rpm, centrifuge for 30min, filter through 9 layers of gauze, and collect the supernata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com