Water-soluble stoving varnish suitable for craft glass products and preparation method thereof

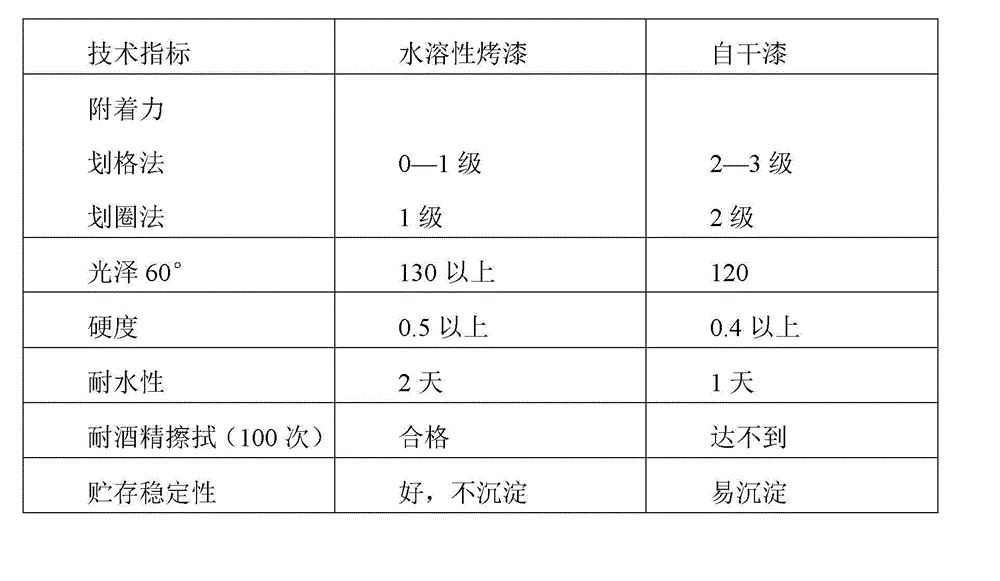

A glass product, water-soluble technology, applied in coatings and other directions, can solve the problems of water resistance, poor alcohol wiping resistance, inferior to baking paint performance, insufficient adhesion, etc., to save costs, improve labor protection, and small environmental impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Water-soluble baking varnish suitable for craft glass products, the components in the formula and their weight percentages are: 28% water-soluble acrylic resin, 9% water-soluble methyl etherified amino resin, 5% silica matting agent, superfine magnesium Powder 8%, ethylene glycol butyl ether 14%, absolute ethanol 19%, water 13.5%, self-emulsifying modified polyacrylate 0.5%, fluorocarbon modified polyacrylate 0.5%, modified polysiloxane 0.5% , Dimethylethanolamine 2%.

[0035] The preparation method of this water-soluble baking varnish comprises the following steps:

[0036] (1) Select each component according to the formula, add water-soluble acrylic resin and water-soluble methyl etherified amino resin into the stainless steel paint mixing tank, the stainless steel paint mixing tank is equipped with a disperser, start the disperser for a stirring, and disperse during the first stirring The rotating speed of machine is 600 rev / mins, and stirring time is 20 minutes;

...

Embodiment 2

[0041] Water-soluble baking varnish suitable for craft glass products, the components in the formula and their weight percentages are: 35% water-soluble acrylic resin, 6% water-soluble methyl etherified amino resin, 3% silica matting agent, superfine magnesium Powder 5%, ethylene glycol butyl ether 10%, absolute ethanol 17.4%, water 17%, self-emulsifying modified polyacrylate 0.2%, fluorocarbon modified polyacrylate 0.2%, modified polysiloxane 0.2% , Dimethylethanolamine 6%.

[0042] The preparation method of this water-soluble baking varnish comprises the following steps:

[0043] (1) Select each component according to the formula, add water-soluble acrylic resin and water-soluble methyl etherified amino resin into the stainless steel paint mixing tank, which is equipped with a disperser, start the disperser for a stirring, once stirring The rotating speed of the disperser is 700 rpm, and the stirring time is 15 minutes;

[0044](2), uniformly mix ethylene glycol butyl ethe...

Embodiment 3

[0048] Water-soluble baking varnish suitable for craft glass products, the components in the formula and their weight percentages are: 34% water-soluble acrylic resin, 8% water-soluble methyl etherified amino resin, 4% silica matting agent, superfine magnesium Powder 7%, ethylene glycol butyl ether 13%, absolute ethanol 15%, water 14.9%, self-emulsifying modified polyacrylate 0.3%, fluorocarbon modified polyacrylate 0.4%, modified polysiloxane 0.4% , Dimethylethanolamine 3%.

[0049] The preparation method of this water-soluble baking varnish comprises the following steps:

[0050] (1) Select each component according to the formula, add water-soluble acrylic resin and water-soluble methyl etherified amino resin into the stainless steel paint mixing tank, the stainless steel paint mixing tank is equipped with a disperser, start the disperser for a stirring, and disperse during the first stirring The rotating speed of machine is 650 rev / mins, and stirring time is 16 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com