Cooling liquid composition

A technology of composition and cooling liquid, which is applied in the field of aviation aircraft, can solve the problems of corrosion, foam degree and rubber expansion degree without clear requirements for total alkali reserve, and achieve the effect of reliable performance and high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Add 100g of qualified base oil (PAO) into a temperature-controllable 200mL reaction kettle and heat it to a range of 80°C to 100°C, then add 2.4g of antioxidant 2,6-di-tert-butylphenol, 0.2g of anti-corrosion agent benzotriazole-aldehyde-amine condensate, and 0.01g antifoaming agent T901, after stirring for about 30 minutes to mix evenly, cool down to room temperature, and filter to obtain the cooling liquid composition product, wherein the weight ratio of antioxidant to preservative is 10:1.

Embodiment 2 to 14

[0065] The cooling liquid composition products of Examples 2 to 14 were prepared according to the same method as in Preparation Example 1, except that the components in Preparation Example 1 were replaced by the weights of the various components in Table 1 below.

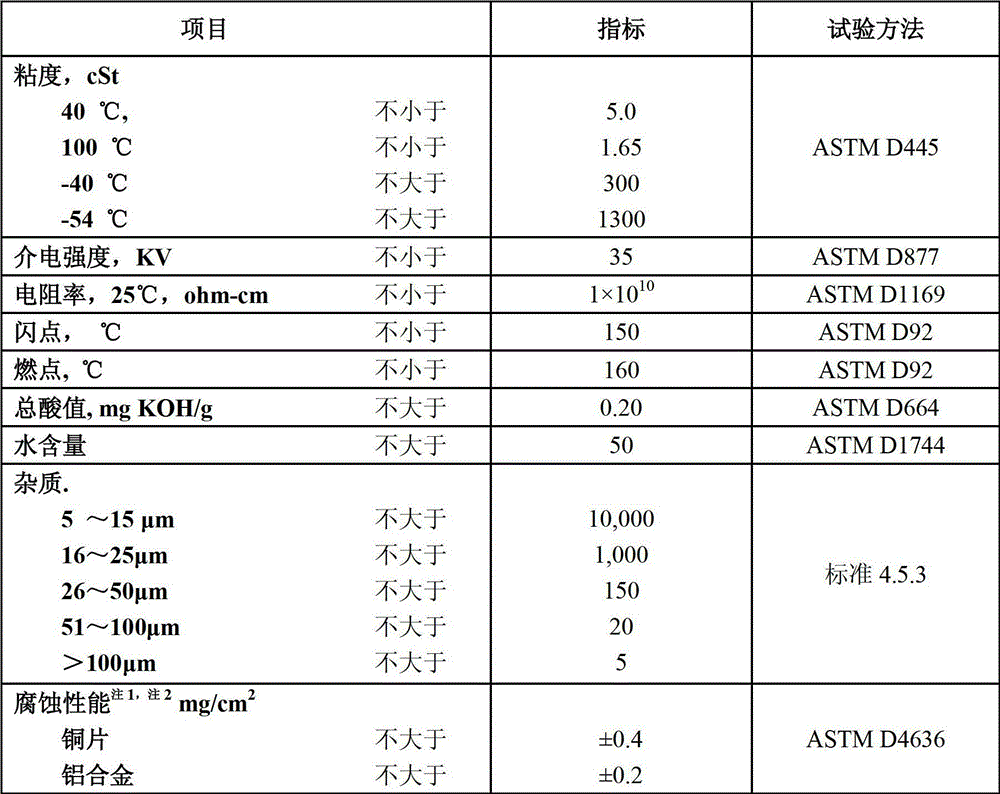

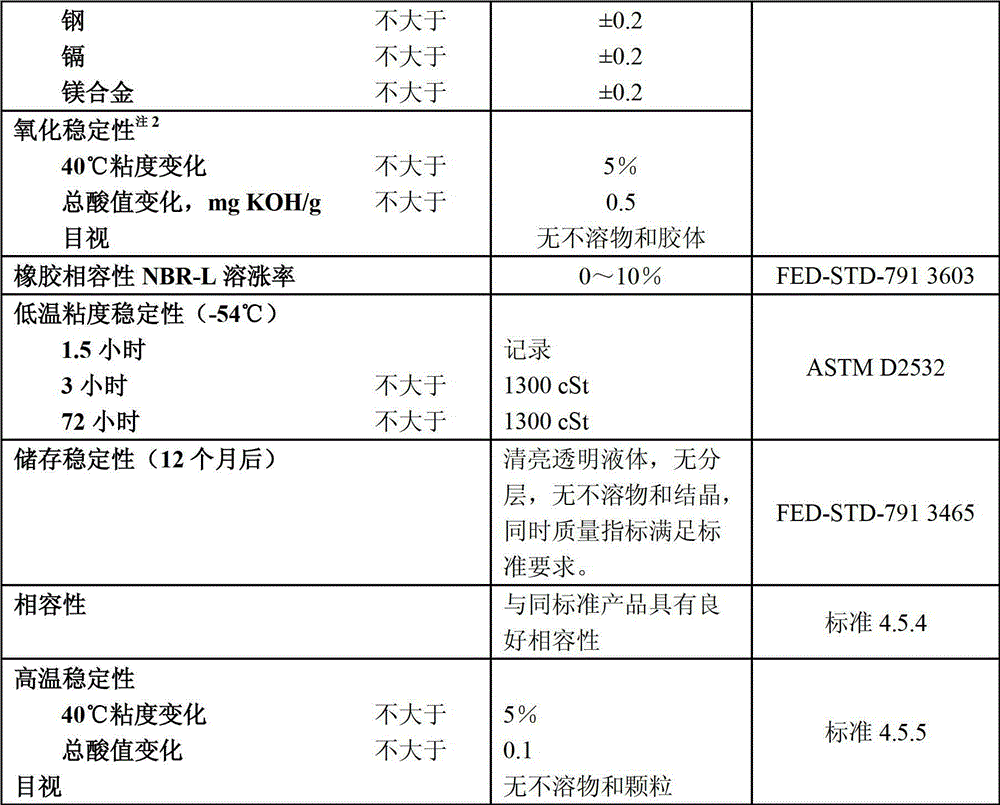

[0066] Table 1

[0067]

[0068]

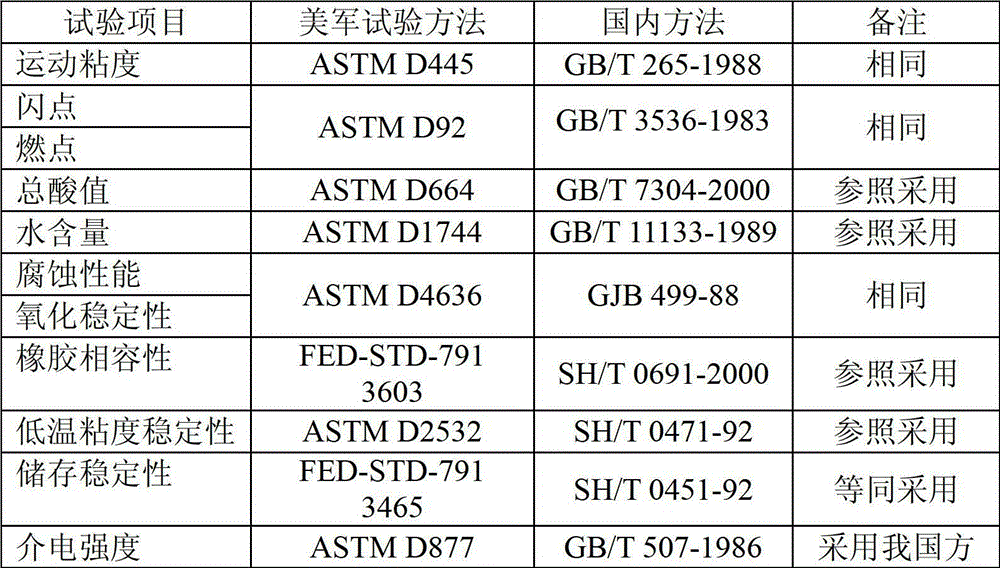

[0069] Test Example

[0070] In the test example, the imported synthetic hydrocarbon cooling liquid was used to carry out the comparative test, and the imported synthetic hydrocarbon cooling liquid was the royal brand synthetic hydrocarbon dielectric cooling liquid produced by British royal company.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com