Liquid crystal slit grating and three-dimensional display device and manufacturing method of liquid crystal slit grating and three-dimensional display device

A slit grating, liquid crystal technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of uneven voltage distribution of liquid crystal slit gratings, high driving voltage of liquid crystal slit gratings, affecting yield and picture quality, etc. Achieve the effect of improving display quality and process yield, improving voltage distribution uniformity and voltage distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

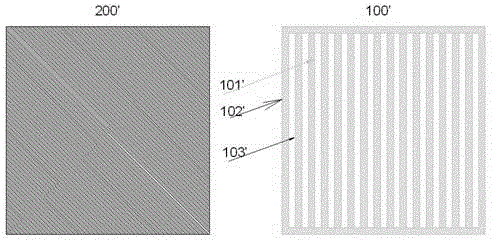

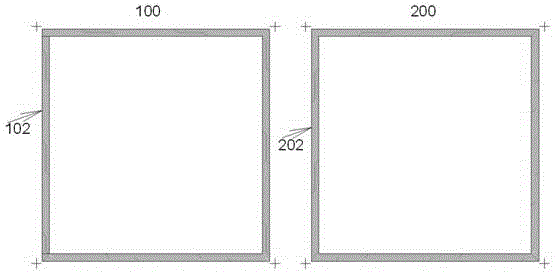

[0041] Existing technologies such as figure 1 As shown, 100' and 200' represent the upper and lower glass substrates of the liquid crystal slit grating respectively, 101' represents the ITO electrode of the liquid crystal slit grating, 102' represents the peripheral electrode of the liquid crystal slit grating, there is no ITO electrode at 103', and the glass substrate The surface of 200' is the entire surface of ITO, which is used as a common electrode.

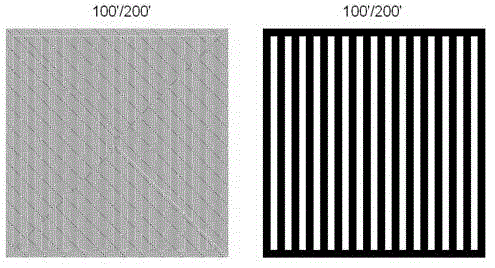

[0042] Such as figure 2 As shown, the left picture shows the situation after the upper and lower glass substrates 100' and 200' of the liquid crystal slit grating are assembled; ', 200' The black and white stripes formed by the upper and lower polarizers on the outer surface and whose polarization directions are perpendicular to eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com