Inorganic mineral wrapped insulated flexible fire-proof cable provided with crimping stainless steel sheath and fabrication method of flexible fire-proof cable

A technology of wrapping insulation and inorganic minerals, which is applied in the direction of insulated cables, cable/conductor manufacturing, and insulated conductors. It can solve the problems of easy oxidation of copper materials, inability to produce large lengths, and airtightness assessment, so as to reduce hidden dangers of joints, Effects of reducing accessory costs and ensuring electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

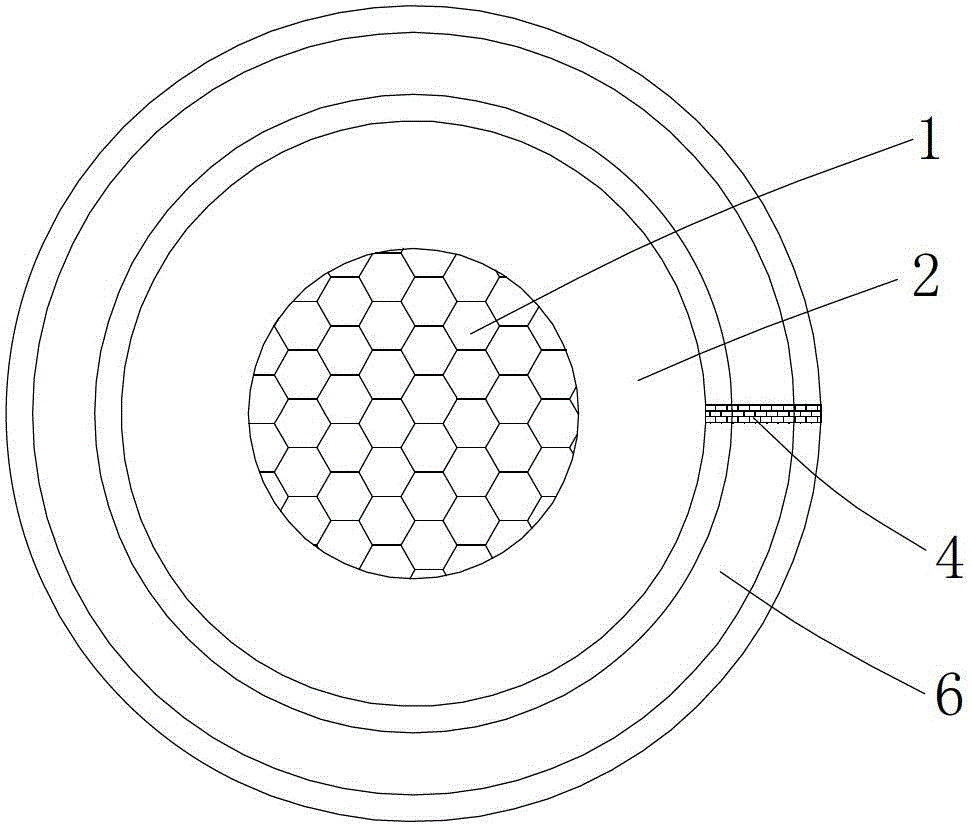

[0043] Example 1: Combining figure 1, the fireproof cable of this embodiment, the cable core is composed of a conductor 1 and an insulating layer 2 wrapped around the conductor, the conductor is formed by twisting and pressing 1-61 copper wires, and an inorganic fire-resistant synthetic mica tape is used outside the conductor The insulating layer 2 is formed by stacking and wrapping, and the number of wrapping layers is 5-9 layers. After the insulating layer is wrapped, it is dried and passed the spark withstand voltage test. After the test is passed, the stainless steel strip is longitudinally wrapped and embossed to form an outer sheath 6 , the thickness of the stainless steel strip is 0.30-2.00mm, the embossing depth is 0.5-4.0mm, the embossing distance is 3-8mm, the embossing is equidistant embossing, and the weld 4 is formed after embossing. The stainless steel strip after embossing and The distance between the cable cores is generally about 0.5 mm. The finished product...

Embodiment 2

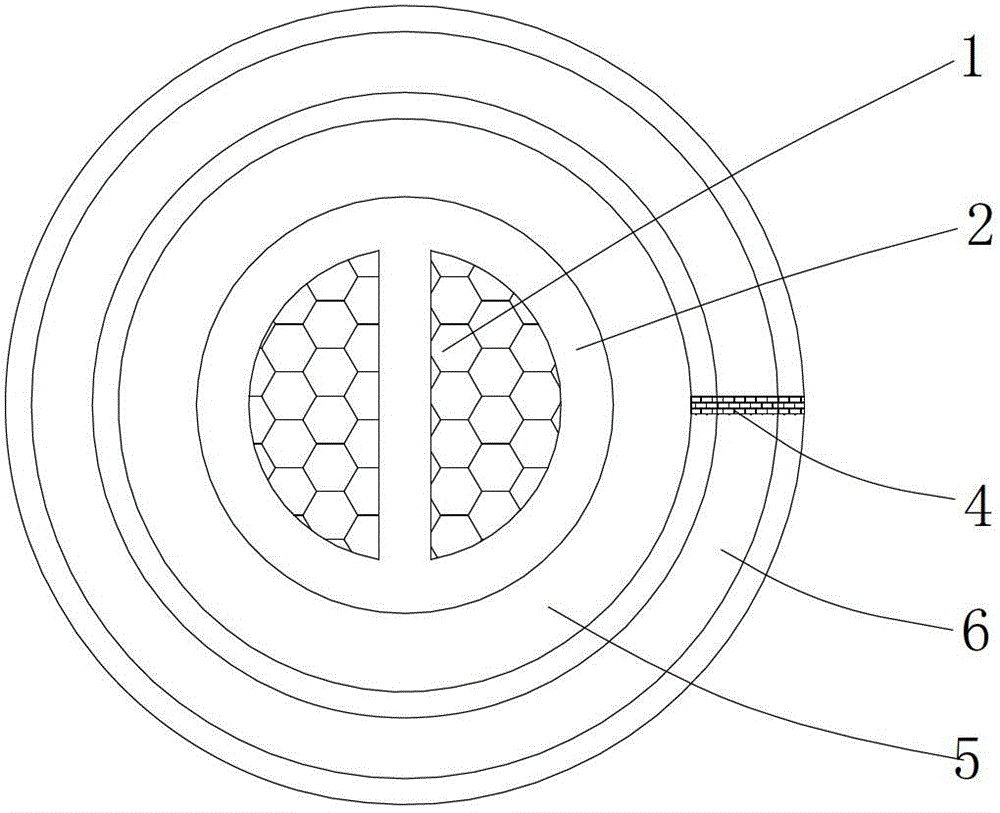

[0044] Example 2: Combining figure 2 In the fireproof cable of this embodiment, the conductor is two-core semicircular stranding, the conductor is wrapped with 5-9 layers of insulating layer 2, and the insulating layer is wrapped with 4-7 layers of second insulating layer 5. Each semicircular conductor is formed by twisting and pressing 1-61 copper wires. The insulating layer 2 is composed of inorganic fire-resistant synthetic mica tapes, and the two-core conductors are twisted to the right. The stainless steel strip is longitudinally covered with embossing treatment, and the weld seam 4 is formed after embossing, and undergoes a pressurized inflation test. The subsequent process after wrapping the second insulating layer is the same as that of Embodiment 1.

Embodiment 3

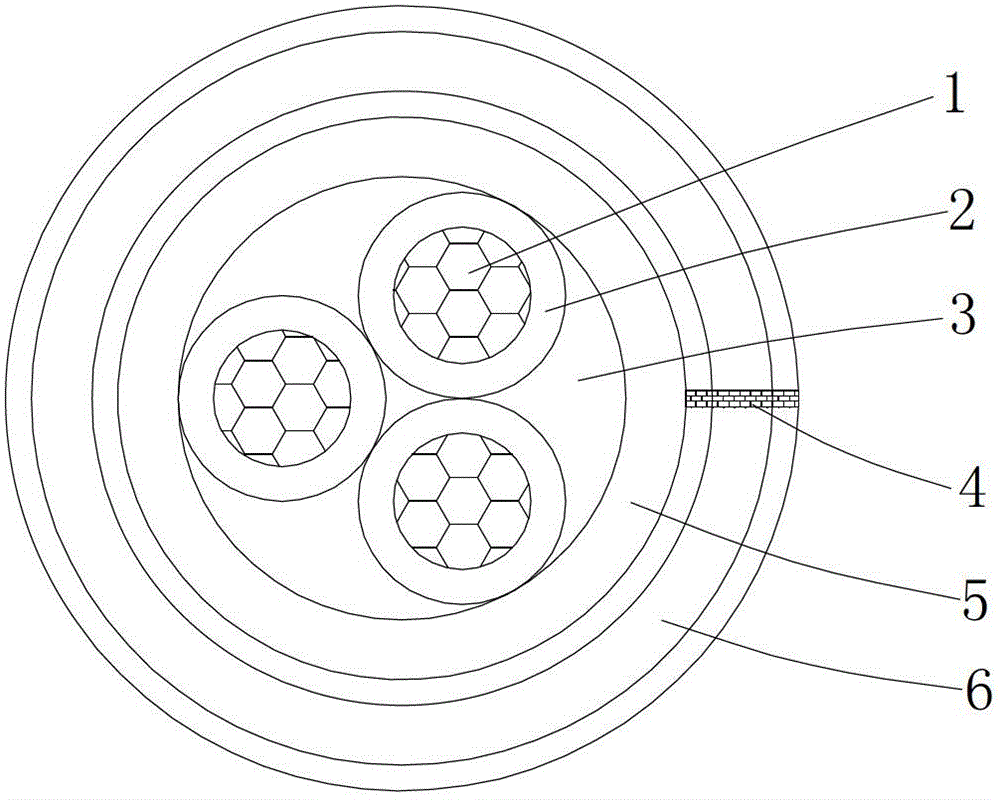

[0045] Example 3: Binding image 3 , the fireproof cable of this embodiment, the conductor is a three-core cylindrical conductor, each conductor is wrapped with 5 to 9 layers of insulating layers, and a single conductor is formed by twisting and pressing 1 to 61 copper wires, and after insulation After drying and passing the spark withstand voltage test, three cylindrical insulated wire cores are cabled and combined, the twisting direction of the cable is right, the gap between the cable cores is filled with inorganic fire-resistant filling rope 3, and then wrapped with 4 to 7 layers of second insulating layer , after the second insulating layer is wrapped, the stainless steel strip is longitudinally wrapped and embossed, and the weld 4 is formed after the embossing, and it is subjected to a pressurized inflation test. The subsequent process after the second insulation layer wrapping is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com