Restraining machine used for edible mushroom device cultivation

A technology for facility cultivation and edible fungi, applied in the field of facility cultivation, can solve the problems of inconsistent growth of edible fungi, uneven ventilation and lighting, affecting economic benefits, etc., and achieve high-quality finished products, uniform control of lighting and ventilation, and uniform growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

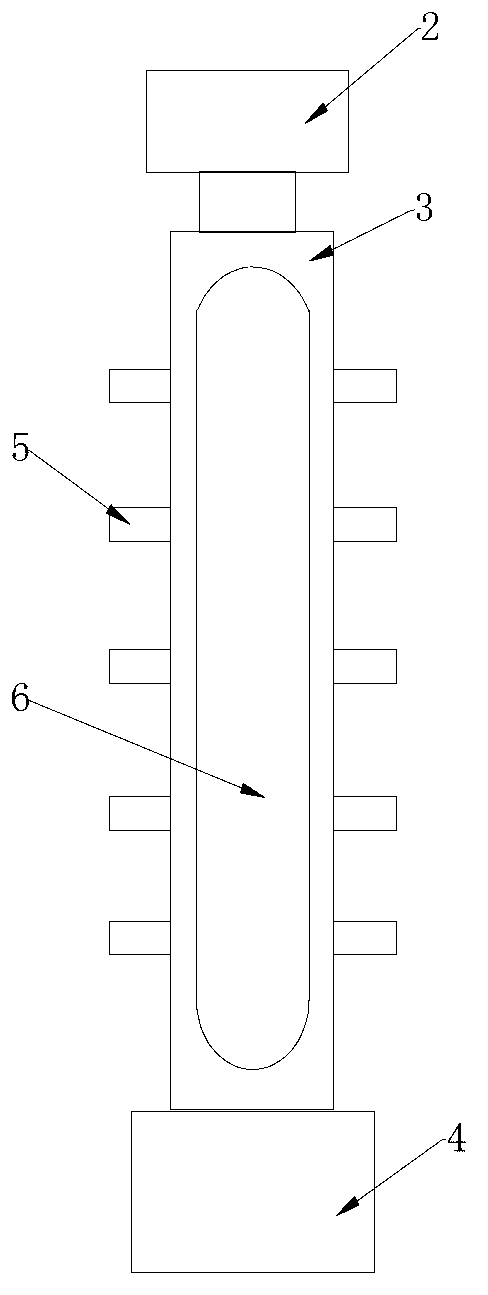

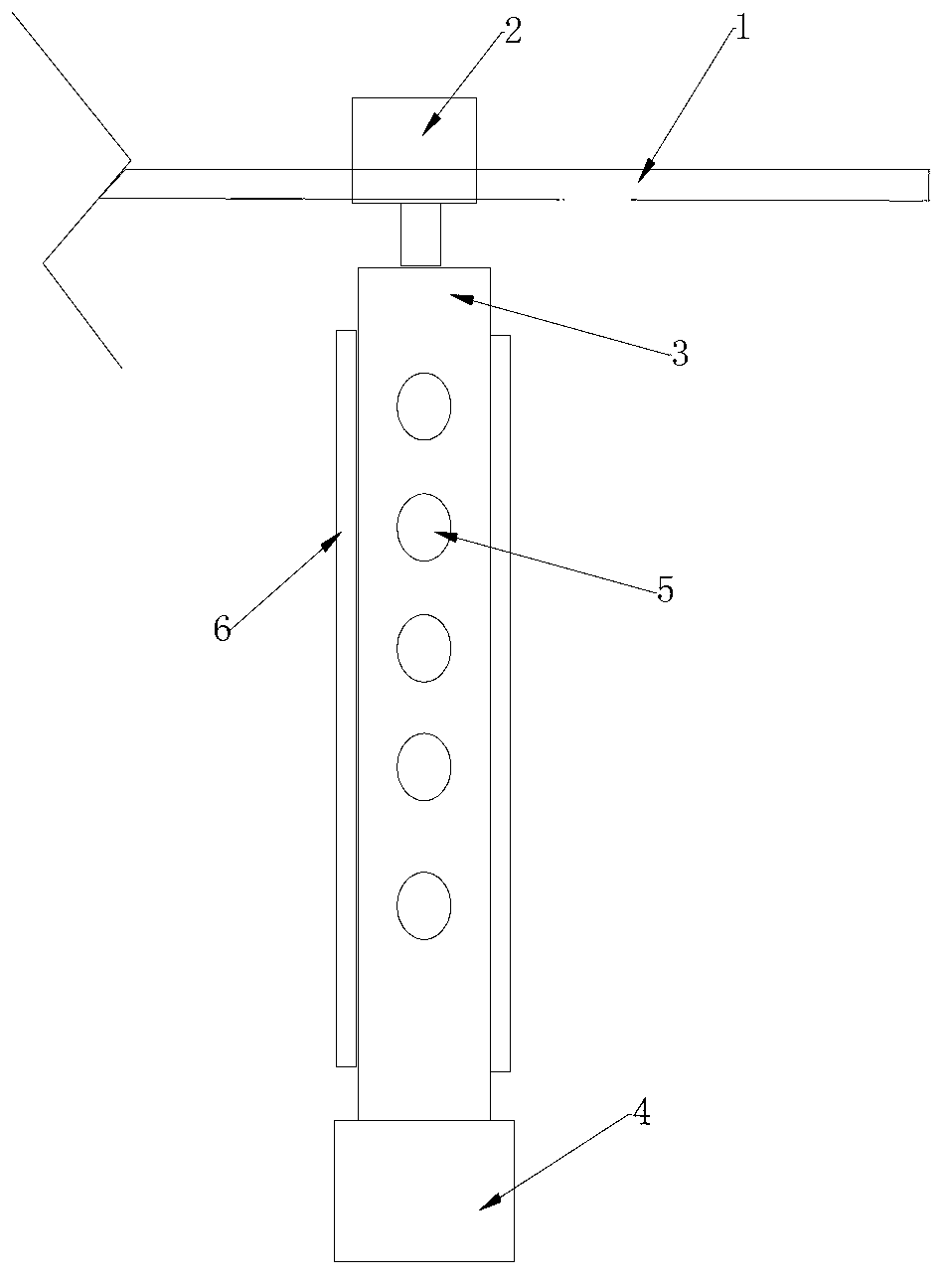

[0015] Such as figure 1 , figure 2 As shown, the present invention comprises a track 1 that is fixed on the ceiling, and a travel motor 2 is installed on the track 1, and a body 3 is suspended below the travel motor 2, and the left and right sides of the body 3 each have an air duct 5 to be listed. A lamp tube 6 is provided at the front end and / or the rear end. The body 3 is a hollow pipe body, the body 3 communicates with the air outlet pipe 5, the lower end of the body 3 is provided with a blower 4, the air outlet of the blower 4 communicates with the body 3, and an automatic limiter is installed on the walking motor 2, Controlled by the limit switch, when the suppressor runs to both ends, it can turn back. In order to ensure the safety of the device, a limit position baffle can also be fixed at both ends of the track 1. When the suppressor moves to this position, the limit baffle will touch the handle of the travel switch and cut off the power to control the travel. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com