RFID-based train intelligent comprehensive supervision system and its working method

A supervision system and comprehensive management technology, which is applied to the control system of the transportation center, railway car body parts, railway traffic management, etc., can solve the problems of inability to effectively locate the area, tired of inspection work, and less information, and achieve The effect of scientific and standardized personnel management, improvement of management level and work efficiency, and low-failure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will be further described in detail below in conjunction with the accompanying drawings.

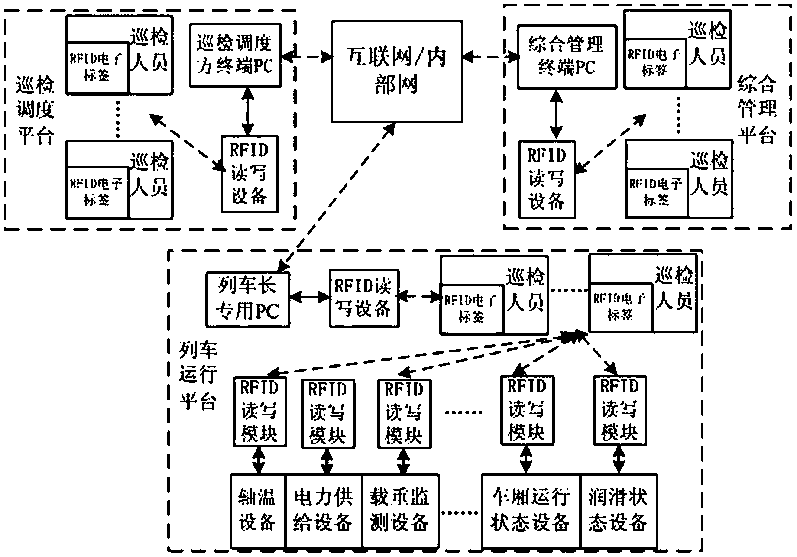

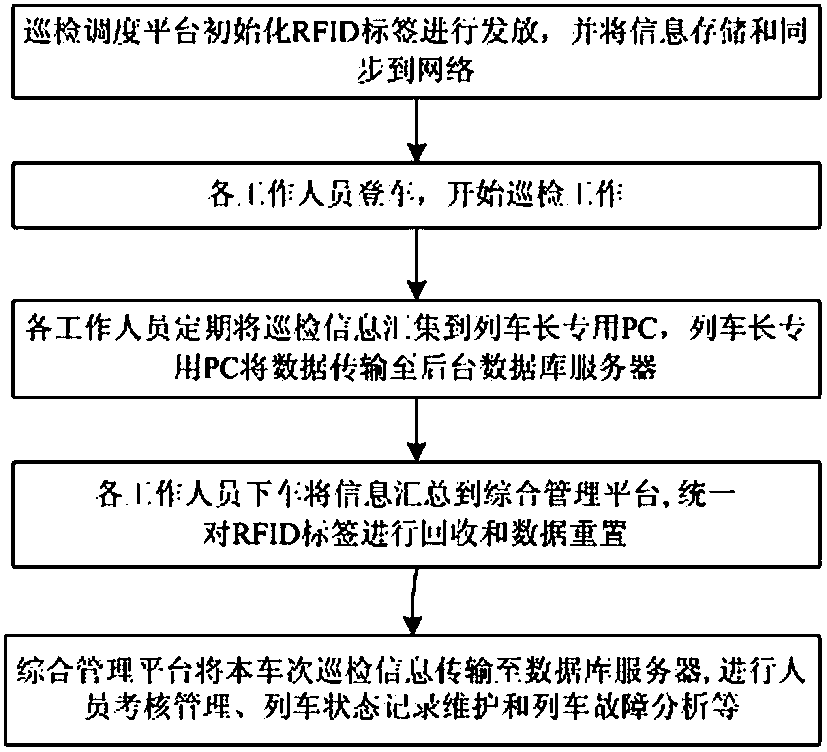

[0033] Such as figure 1 As shown, the schematic diagram of the RFID-based intelligent integrated monitoring system for trains provided by the present invention. The system architecture includes three platforms: an inspection dispatch platform, a train operation platform, and an integrated management platform. In addition, it also needs to cooperate with the network platform of the railway department. Complete system management together.

[0034] The inspection dispatching platform consists of the inspection dispatcher terminal PC, RFID electronic tags, and RFID reading and writing equipment. RFID electronic tags and RFID reading and writing equipment for reading and writing communication, RFID reading and writing equipment as an external data interface and the inspection dispatcher terminal PC through RS232 or USB interface connection, inspection dispatcher terminal PC th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com