Method for degrading organic wastewater by adopting active carbon-based microwave catalyst

A technology of organic wastewater and activated carbon, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low degradation efficiency, high cost, and long processing time , to achieve the effect of no secondary pollution, less floor space, and complete degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

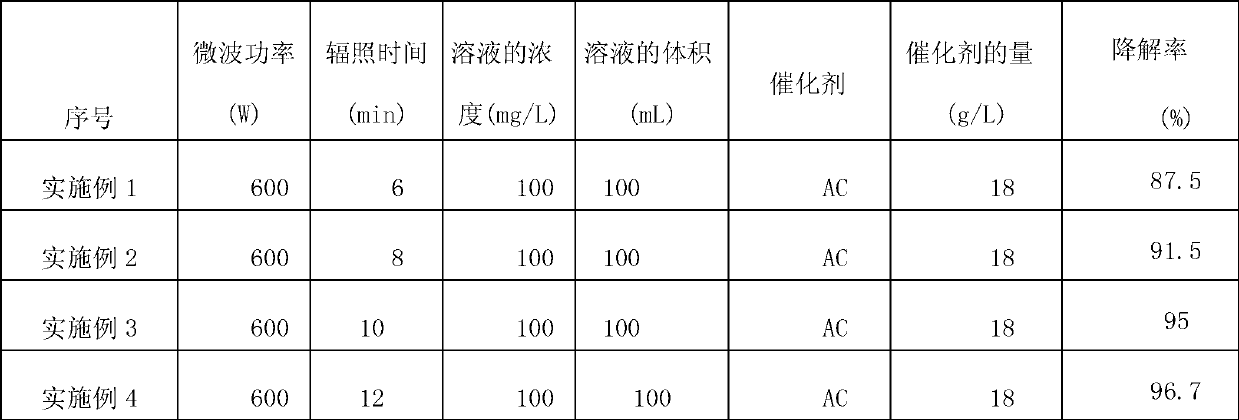

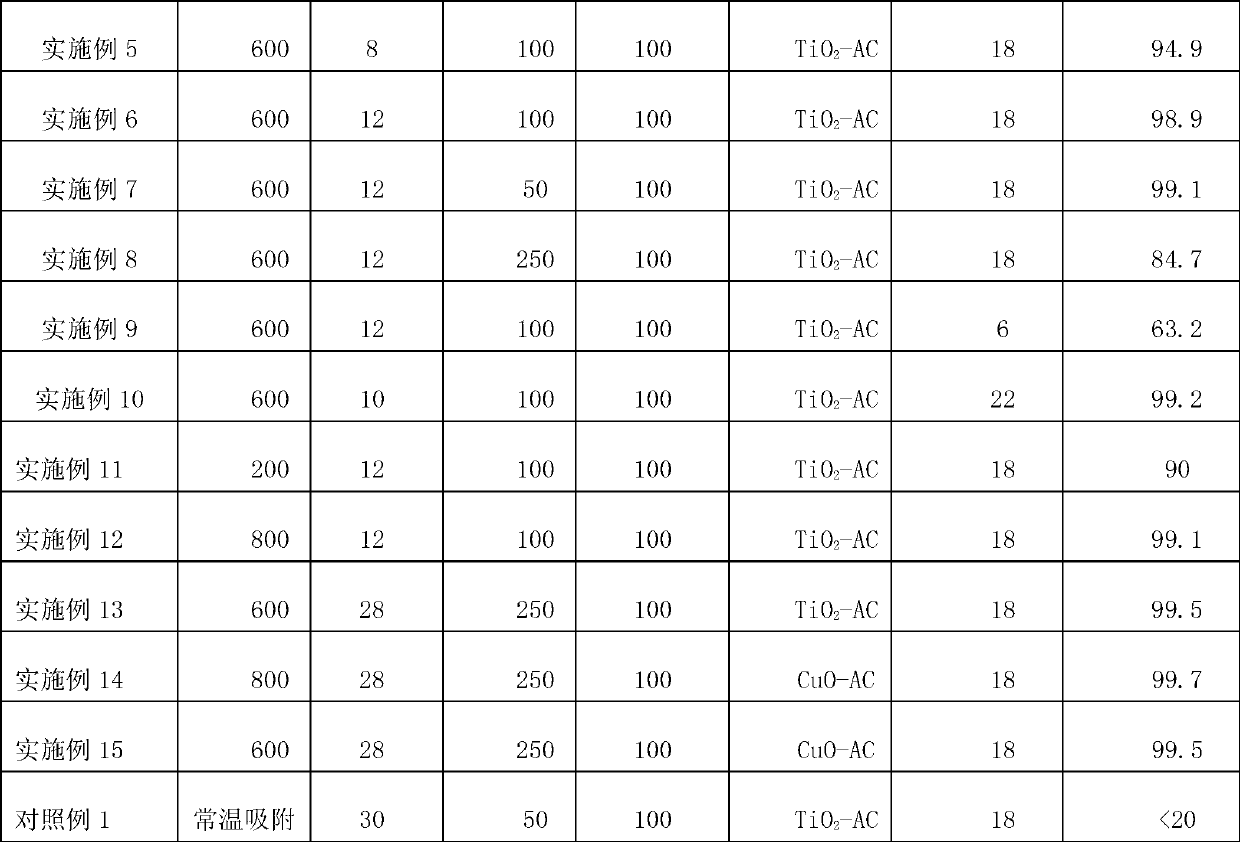

Examples

preparation example Construction

[0024] TiO 2 -Preparation of AC microwave catalyst: add a certain amount of butyl titanate to rapidly stirring absolute ethanol, continue to stir for 30 minutes, add a certain amount of acetylacetone, and stir for another 30 minutes, then dropwise add absolute ethanol and deionized The mixed solution of water and concentrated nitric acid was added dropwise, stirred at a low speed for 2 hours, added 20 g of pretreated activated carbon, stirred for 2 hours, and placed in an ultrasonic cleaner for 3 hours. At this time, the obtained gel was left to stand for 24 h, and dried at 80° C. for 20 h. Calcined at 450°C for 2h. That is, the desired supported catalyst is obtained.

[0025] Preparation of CuO / AC catalyst: firstly, the carrier granular activated carbon was boiled and washed with deionized water, and dried for 12 hours; the activated carbon was impregnated with an equal volume of copper nitrate (Cu(NO3)2) solution by impregnation method, and after standing at room temperatu...

Embodiment 1

[0027] The microwave catalyst used is activated carbon: measure 100mL of 100mg / L methyl orange wastewater in a 500mL conical flask, add 1.8g of catalyst, after the catalytic reaction under the condition of microwave power of 600W for 6min, take the supernatant, and use The absorbance was measured by an ultraviolet-visible photometer, and the degradation rate was calculated to be 87.5%.

Embodiment 2

[0029] The microwave catalyst used is activated carbon: measure 100mL of 100mg / L methyl orange waste water in a 500mL conical flask, add 1.8g of catalyst, after the catalytic reaction under the condition of microwave power of 600W for 8min, take the supernatant, use The absorbance was measured by an ultraviolet-visible photometer, and the degradation rate was calculated to be 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com