Method for continuously synthesizing cumarin by microchannel reactor

A micro-channel reactor, coumarin technology, applied in the field of chemical synthesis and technology, can solve the problems of complex process, long production cycle, pollution of the environment, etc., and achieve the effects of high product conversion rate, short reaction time, and overcoming large dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~19

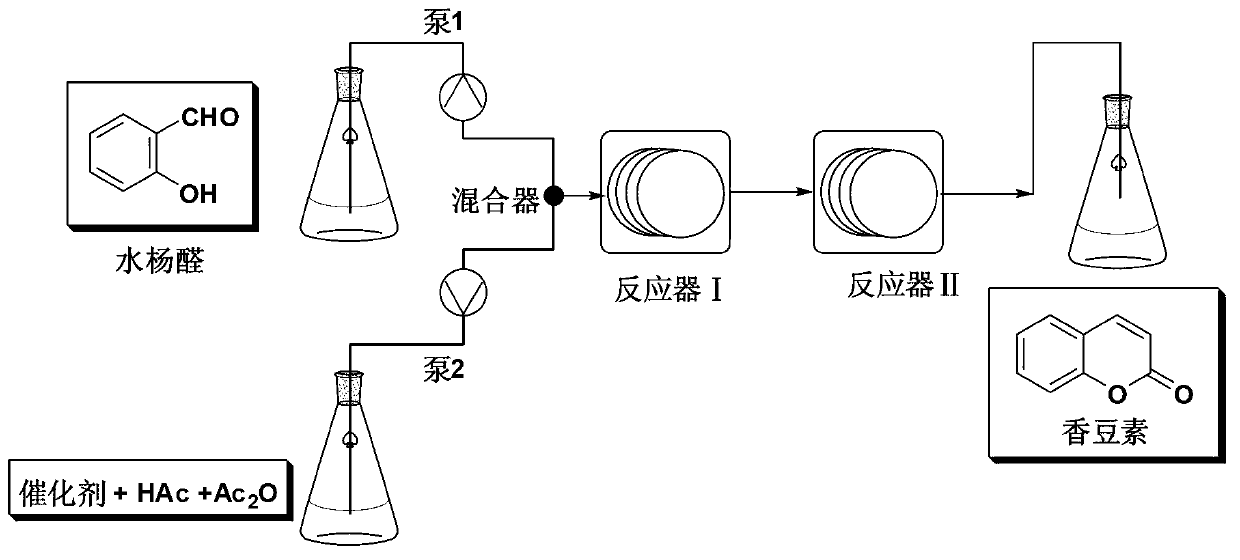

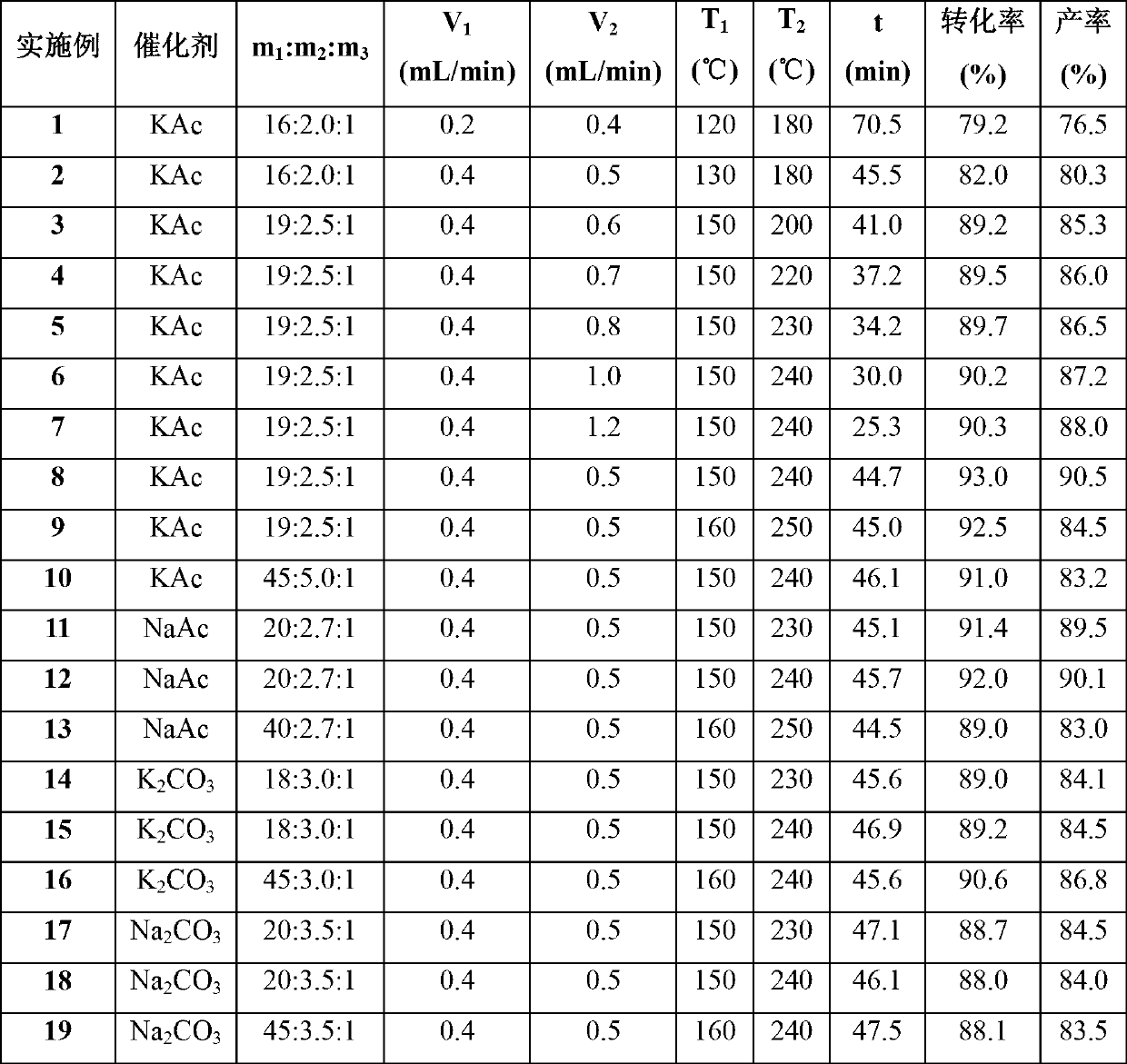

[0030] The catalyst is dissolved in the mixed solution of acetic anhydride and acetic acid, the mass ratio of acetic anhydride, acetic acid and catalyst is m 1 :m 2 :m 3 ; Salicylaldehyde and the above-mentioned mixture according to the flow volume ratio V 1 :V 2 Pumped into the microchannel reactor respectively, successively pass through the reactor I and the reactor II connected in series in the microchannel reactor, the total residence time in the reactor I and the reactor II is respectively t, and the reaction temperature is respectively T 1 and T 2 ; Microchannel reactor output refining (including conventional vacuum distillation and recrystallization, etc.) to obtain coumarin products. The specific conditions and results of the EHRFELD slit-plate mixer reactor are shown in Table 1. For the Vapourtec R4 / R2+ reactor, only V 1 and V 2 are all halved, other conditions are the same as in Table 1, and the reaction effect is almost equivalent to that of the EHRFELDslit-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com