A high solid epoxy paint

An epoxy paint, high-solid technology, applied in the field of coating paint, can solve the problems of poor hot water resistance and cold and heat resistance, poor adhesion of thick film, etc., to achieve good environmental protection, good chemical resistance, excellent Effects of salt water and fog resistance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Modified epoxy resin KD190 28.27%, modified amine curing agent ZP0084215.12%, pigment 32.58%, toughening agent NC513 3.12%, anti-settling agent organic bentonite 2.36%, mixed solvent 18.55%. The component content of the pigment is calculated by weight percent: 40-60% mica powder, 20-40% talcum powder and 10-30% barium sulfate. The weight ratio of xylene to n-butanol in the mixed solvent is 2:1.

Embodiment 2

[0027] Example 2: Modified epoxy resin KD19032.46%, modified amine curing agent ZP0084217.21%, pigment 29.45%, toughening agent LITE2513HP4.08%, anti-settling agent fumed silica 1.88%, mixed solvent 14.92% . The component content of the pigment is calculated by weight percent: 40-60% mica powder, 20-40% talcum powder and 10-30% barium sulfate. The weight ratio of trimethylbenzene and isopropanol in the mixed solvent is 2:1.

Embodiment 3

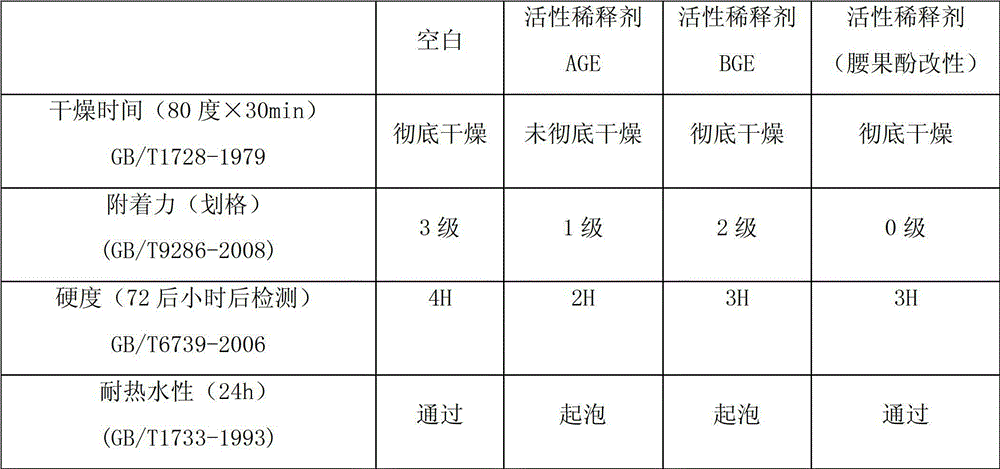

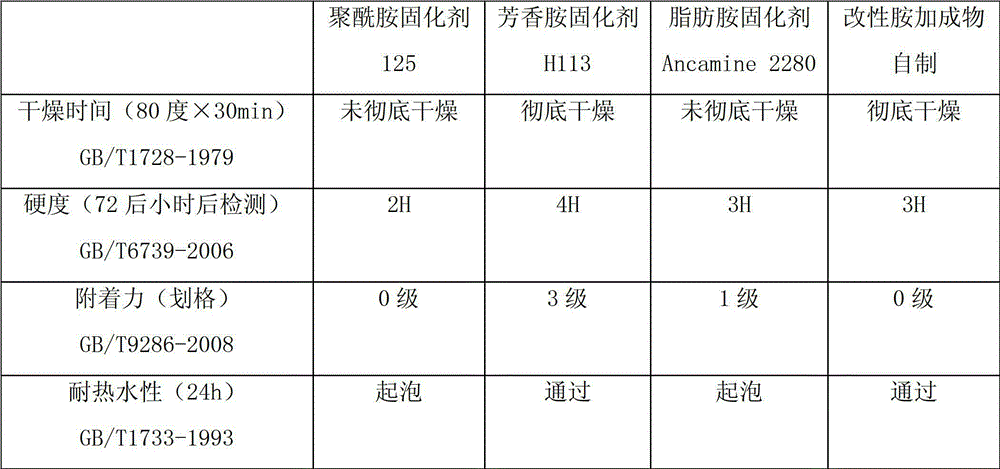

[0028] The influence of embodiment 3 different epoxy resins on paint film performance

[0029] The type of epoxy resin was changed, and the composition and content of other components of the high-solid epoxy paint were the same as in Example 1. The influence of different epoxy resins on the performance of the paint film was investigated. The results are shown in Table 1.

[0030] Table 1: Effect of different epoxy resins on paint film properties

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com