Preparation method for high-efficiency slim stripping bactericide

A bactericide and slime technology, which is applied in the operation field of drainage system, can solve the problems of seldom use, toxicity of isothiazolinone, pollution of aquatic organisms and environment, etc., achieve good slime stripping effect, and demonstrate technological progress. , the effect of rapid dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

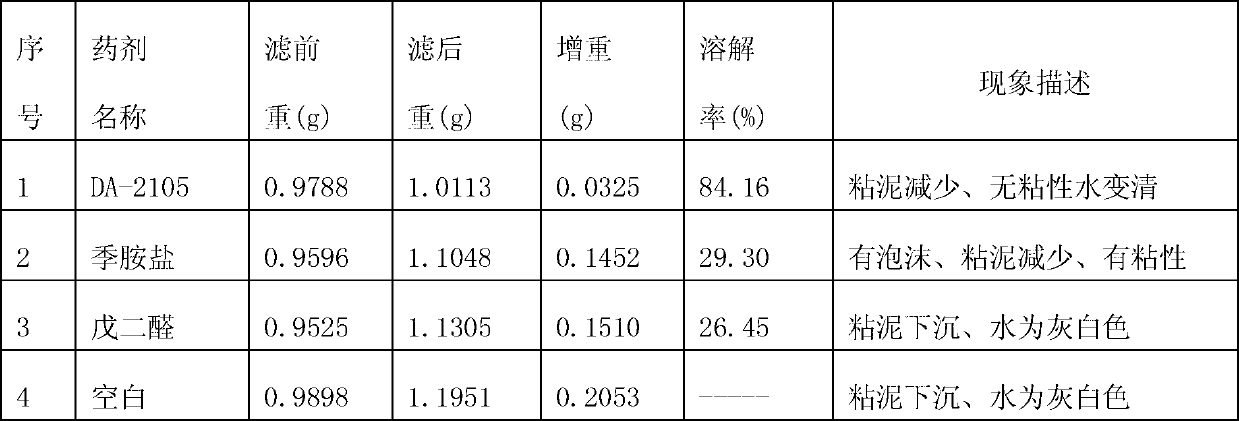

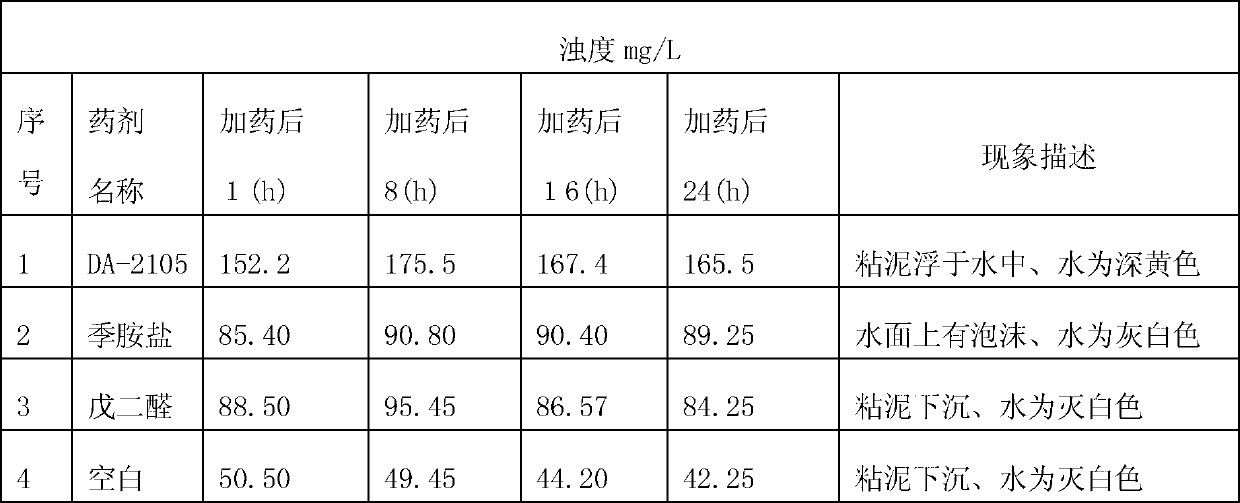

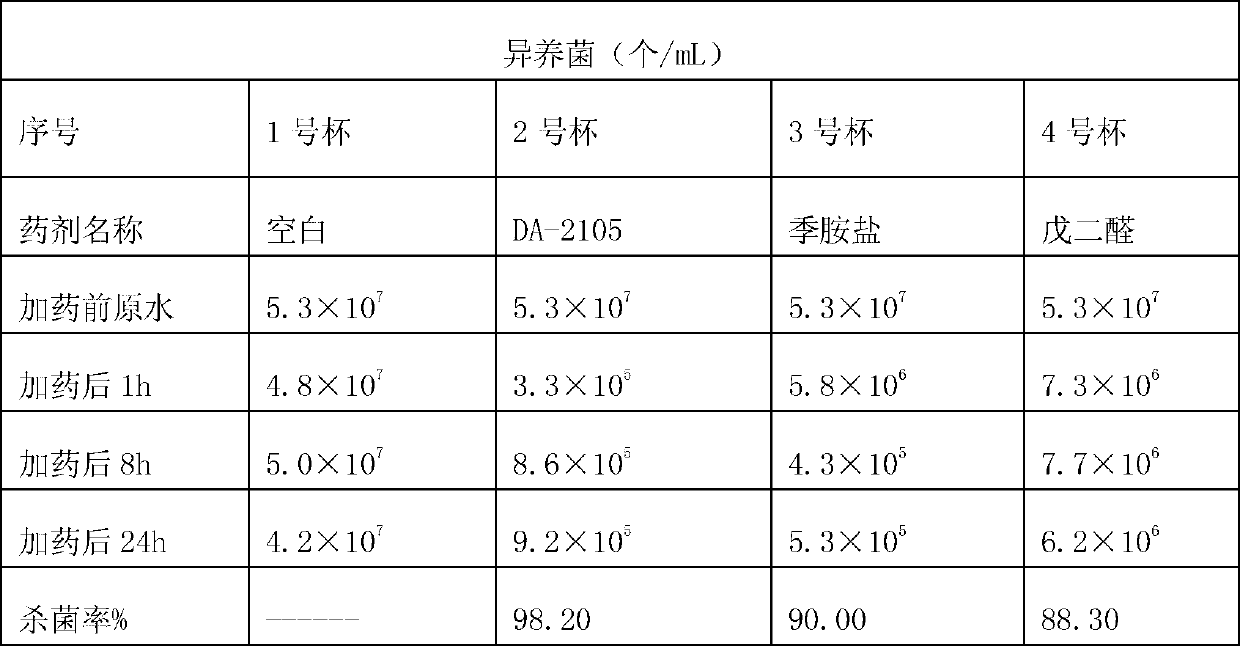

Examples

Embodiment 1

[0016] The preparation of this high-efficiency slime stripping fungicide:

[0017] Raw materials are prepared in parts by weight:

[0018] ① Take 200 parts of dodecyl dimethyl benzyl ammonium chloride, 150 parts of ethanol, 50 parts of isopropanol, 1 part of dioctyl maleate sulfonate, 40 parts of alkylphenol polyoxyethylene ether part, 500 parts of deionized water;

[0019] ②Take 300 parts of dodecyl dimethyl benzyl ammonium chloride, 250 parts of ethanol, 150 parts of isopropanol, 10 parts of dioctyl maleate sulfonate, 60 parts of alkylphenol polyoxyethylene ether parts, 600 parts of deionized water;

[0020] ③ Take 250 parts of dodecyl dimethyl benzyl ammonium chloride, 180 parts of ethanol, 100 parts of isopropanol, 9 parts of dioctyl maleate sulfonate, alkylphenol polyoxyethylene ether 45 parts, 550 parts of deionized water;

[0021] Preparation: ① or ② or ③ choose one group, first pump deionized water into the reactor, then add dioctyl maleate sodium sulfonate and alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com