Method for preparing galactooligosaccharide by use of permeable cell beta-galactosidase

A technology of galactosidase and galacto-oligosaccharide is applied in the field of preparation of galacto-oligosaccharide, which can solve the problem that the product cannot be used directly, and achieve the effects of low production cost, reduced production cost and easy separation and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

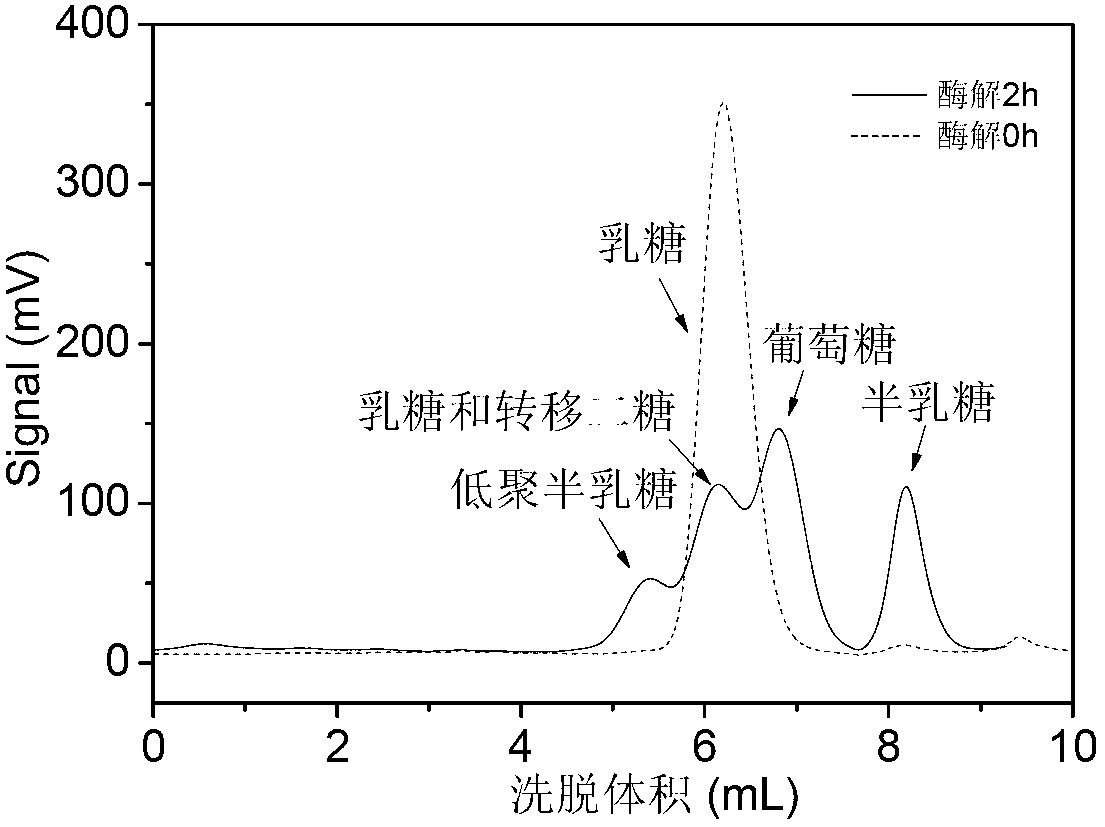

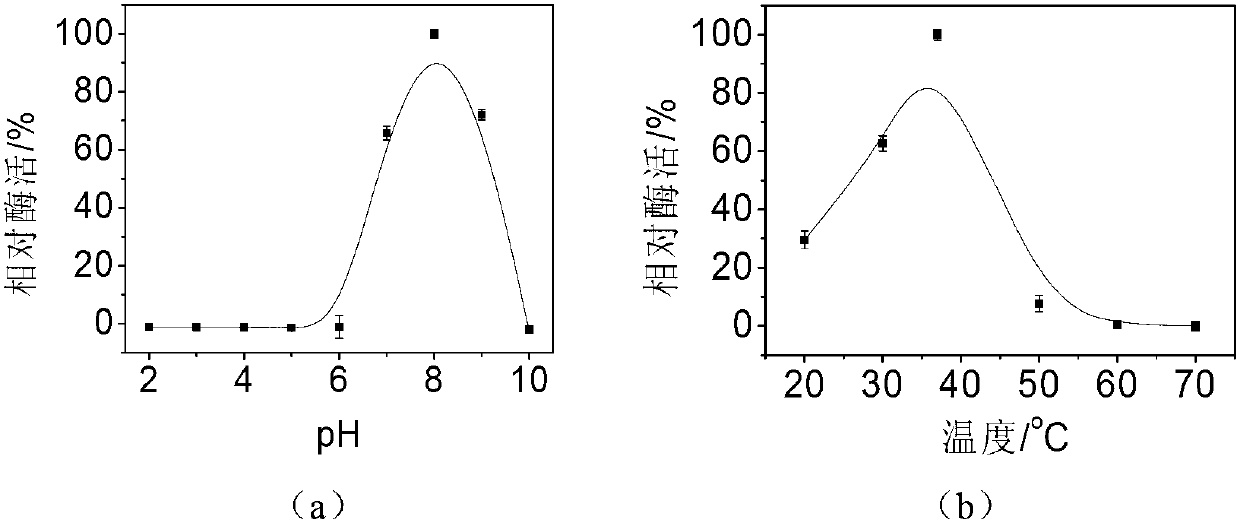

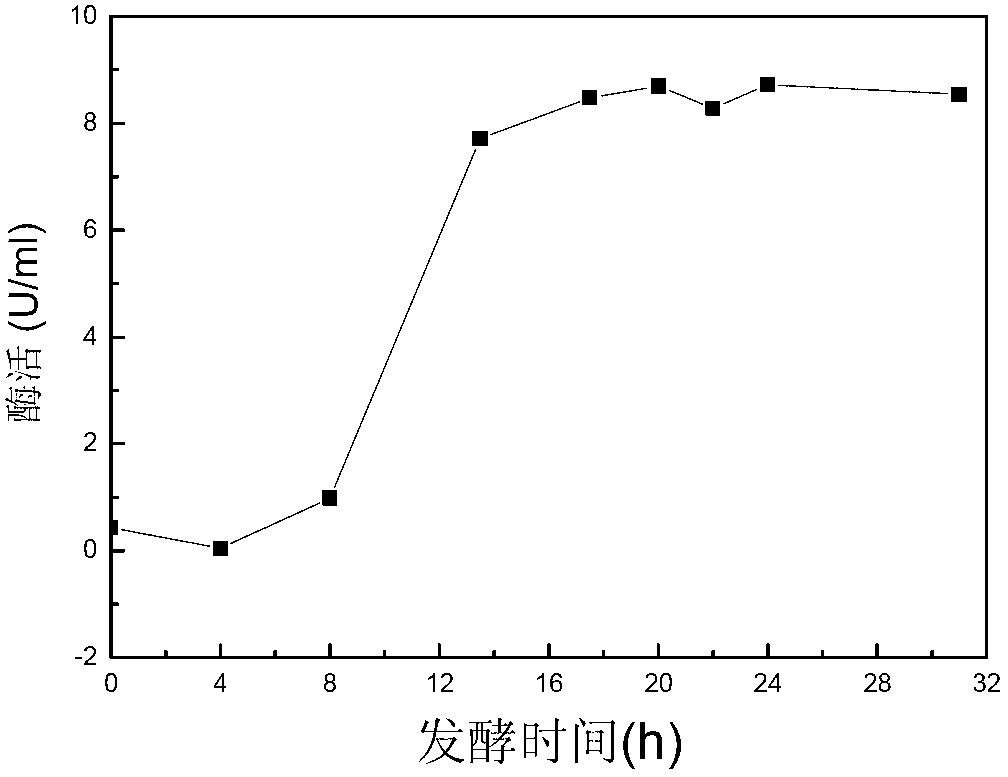

[0027] Preparation of Kluyveromyces lactis permeabilized cells: Fermentation experiments were carried out on Kluyveromyces lactis. The medium composition was: 3.0g yeast extract, 3.0g malt extract, 5.0g peptone, 20.0g lactose, 1.0L distilled water, pH 7.0, autoclave at 121°C for 20min. The fermentation conditions were: 28°C, shaker speed 100rpm, inoculum size 5% (v / v), cultured for 8 hours, and the enzyme activity of the obtained Kluyveromyces lactis fermentation broth was about 1.00U / mL. The fermentation broth was centrifuged at 5000 rpm and 4°C for 5 min, the precipitate was washed with water and then diluted to 50 g / L with PBS buffer to obtain suspension cells. Add absolute ethanol according to the volume ratio of absolute ethanol to suspension cell diluent at 2:5, and shake at 25°C for 1 min. After centrifuging at 5000rpm and 4°C for 5min, the pellet was washed twice with PBS buffer, the supernatant was discarded, and the pellet was taken to obtain the permeabilized cell ...

Embodiment 2

[0030] Preparation of Kluyveromyces lactis permeabilized cells: Fermentation experiments were carried out on Kluyveromyces lactis. The medium composition was: 3.0g yeast extract, 3.0g malt extract, 5.0g peptone, 20.0g lactose, 1.0L distilled water, pH 7.0, autoclave at 121°C for 20min. The fermentation conditions were: 30°C, shaker speed 160rpm, inoculum size 8% (v / v), cultured for 12h, and the enzyme activity of the obtained Kluyveromyces lactis fermentation broth was about 7.00U / mL. The fermentation broth was centrifuged at 5000 rpm and 4°C for 5 min, the precipitate was washed with water and then diluted to 50 g / L with PBS buffer to obtain suspension cells. Add absolute ethanol according to the volume ratio of absolute ethanol to suspension cell diluent at 4:5, and shake at 25°C for 10 min. After centrifuging at 5000rpm and 4°C for 5min, the pellet was washed twice with PBS buffer, the supernatant was discarded, and the pellet was taken to obtain the permeabilized cell β-g...

Embodiment 3

[0033] Preparation of Kluyveromyces lactis permeabilized cells: Fermentation experiments were carried out on Kluyveromyces lactis. The medium composition was: 3.0g yeast extract, 3.0g malt extract, 5.0g peptone, 20.0g lactose, 1.0L distilled water, pH 7.0, autoclave at 121°C for 20min. The fermentation conditions are: 30°C, shaker speed 250rpm, inoculum size 10% (v / v), culture for 20h. The enzyme activity of the obtained Kluyveromyces lactis fermentation broth was about 8.69U / mL. The fermentation broth was centrifuged at 5000 rpm and 4°C for 5 min, the precipitate was washed with water and then diluted to 50 g / L with PBS buffer to obtain suspension cells. Add absolute ethanol according to the volume ratio of absolute ethanol and suspension cell diluent at 1:1, and shake at 25°C for 15 minutes. After centrifuging at 5000rpm and 4°C for 5min, the pellet was washed twice with PBS buffer, the supernatant was discarded, and the pellet was taken to obtain the permeabilized cell β-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com