Electromagnetic valve driving device capable of bearing high frequency switching loss

A technology of solenoid valve drive and high-frequency switching, which is applied to valve devices, valve operation/release devices, valve details, etc., can solve the problems of occupying system software resources and complex implementation structures, and achieve improved drive capability, simple structure, Achieve instant protection and peak limiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

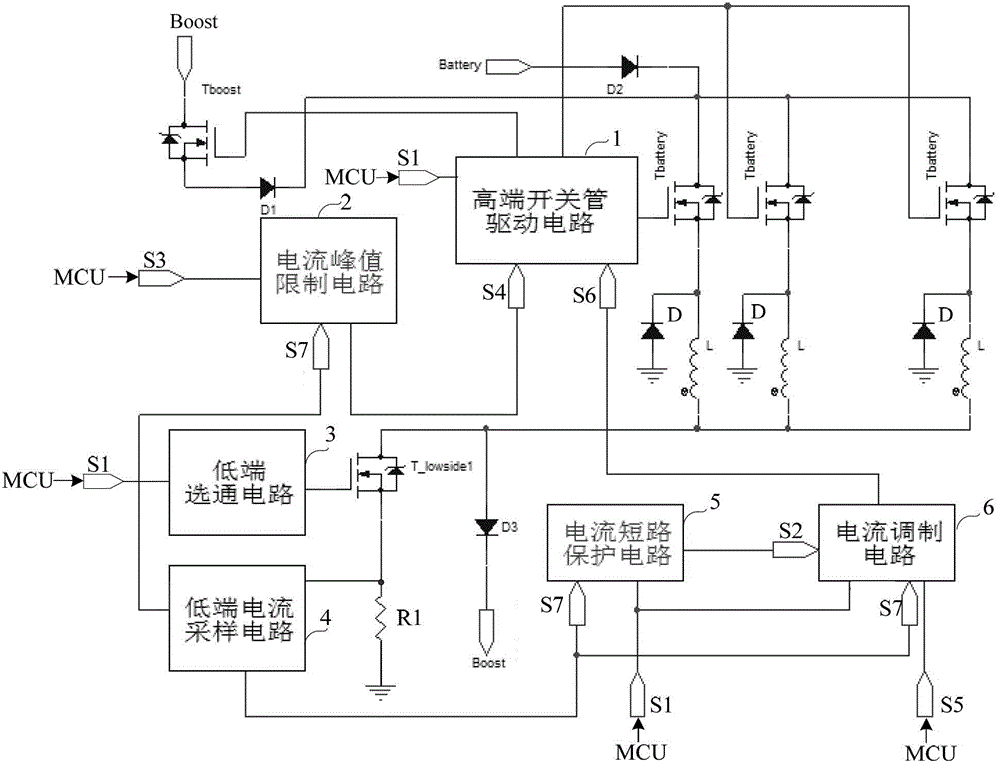

[0021] Such as figure 1 Shown:

[0022] A solenoid valve drive device capable of withstanding high-frequency switching losses, including an MCU, and also includes a high-end switch tube drive circuit 1, a current peak limit circuit 2, a low-end gating circuit 3, a low-end current sampling circuit 4, and a current short-circuit protection circuit 5. Current modulation circuit 6, high voltage switch tube Tboost, multiple high-side drive branches, gate switch tube T_lowside1, first diode D1, second diode D2, third diode D3, sampling resistor R1; Each high-side drive branch includes a modulating switch tube Tbattery, a freewheeling diode D, and an injector solenoid valve L connected in series with the modulating switch tube Tbattery.

[0023] The high-voltage source Boost is connected to the drain of the high-voltage switching tube Tboost, the source of the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com