High-resolution large-range optical fiber strain sensor and probe thereof

A sensor probe, optical fiber strain technology, used in instruments, measuring devices, optical devices, etc., can solve the problems of slow measurement speed, difficult to obtain high precision, limited measurement range, etc., to avoid the scanning process, achieve high-speed measurement, The effect of high strain measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

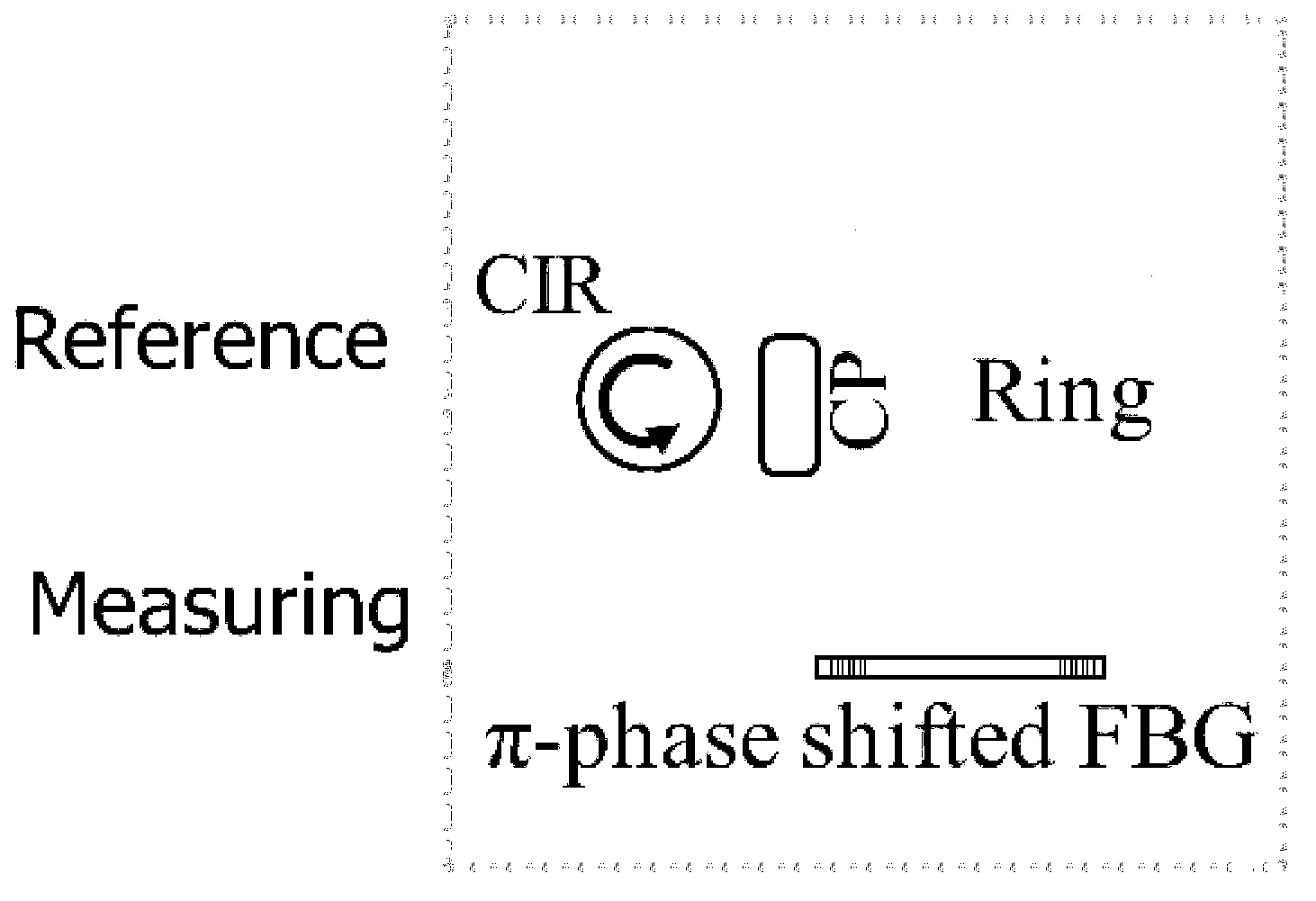

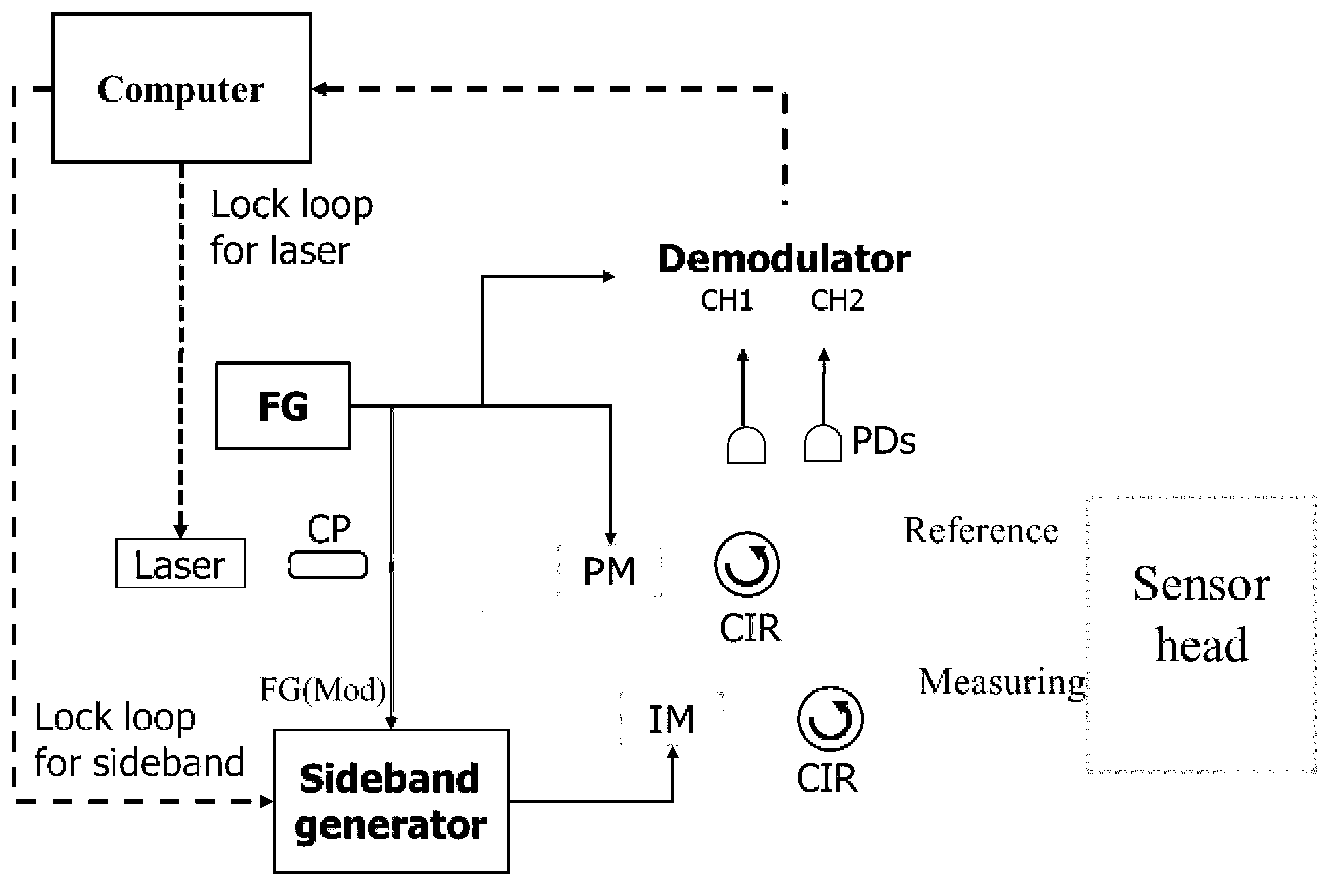

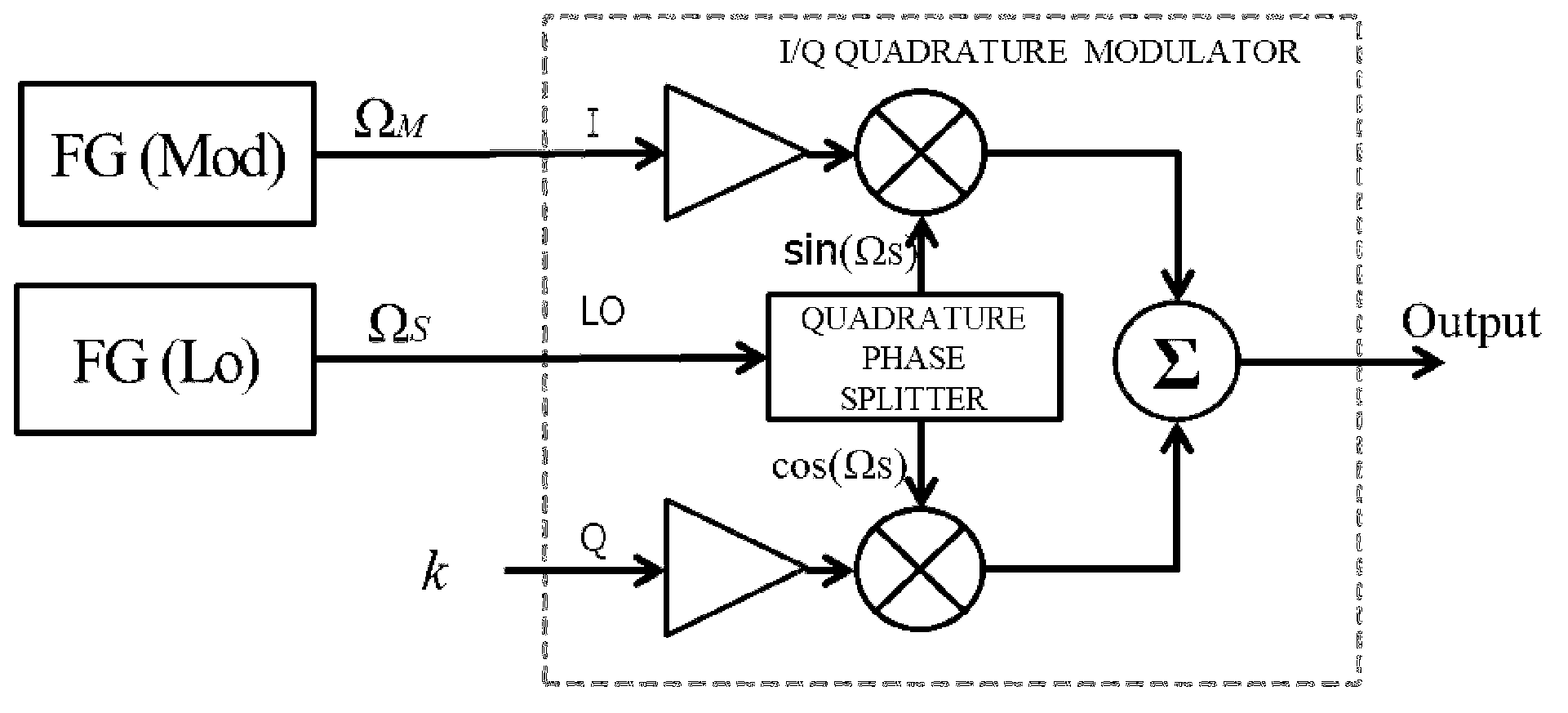

[0020] Such as figure 1 A high-resolution and large-range fiber optic strain sensor probe is shown, which has a fiber ring as a reference and a fiber Bragg grating (FBG) for measuring strain, including ordinary gratings and phase shifted gratings π-phase shifted FBG , the phase-shifted grating has better performance). Fiber Bragg Grating FBG is a strain measurement component, and the deformation to be measured is applied to the FBG; the fiber ring is a reference component, which is not affected by external strain. Fiber ring and FBG are located close to each other to achieve the same temperature. FBG has a resonant frequency (for ordinary FBG, the resonant frequency refers to the optical frequency with high reflectivity; for π-phase shifted FBG, it refers to a very narrow high transmittance in the high reflectivity frequency range optical frequency), which is a linear function of the strain to be measured and temperature, while the fiber ring has some series of discrete res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com