An anti-oxidation treatment method for sintered NdFeB material and its antioxidant

An antioxidant and treatment method technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of unfavorable energy saving and consumption reduction, increase equipment, process, material, energy costs, etc., and achieve the effect of simple and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

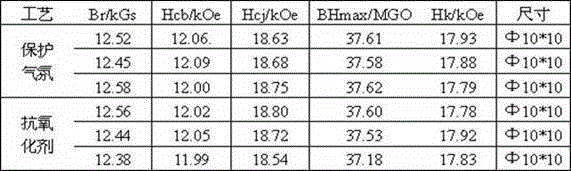

Embodiment 1

[0012] The sintered NdFeB magnets are prepared by the usual sintering method (protective atmosphere process), that is, the conventional jet mill is used, the powder is mixed with nitrogen protective gas, the compression molding is also carried out in an atmosphere filled with argon, and the sintering adopts high vacuum sintering. Three samples were prepared by this method.

[0013] The method (antioxidant process) of the present invention is the same as the method for preparing sintered NdFeB by the usual sintering method, except that 0.05% of the antioxidant benzotriazole and 99.95% of petroleum ether of the present invention are added during jet milling. The powder mixing is carried out in a closed air atmosphere, and the compression molding is also carried out in an air atmosphere. The sintering adopts a low vacuum of 10 Pa. The initial stage of sintering is controlled at a temperature of 180 ° C for 1.5 hours, and the removal of antioxidants is carried out. This method is u...

Embodiment 2

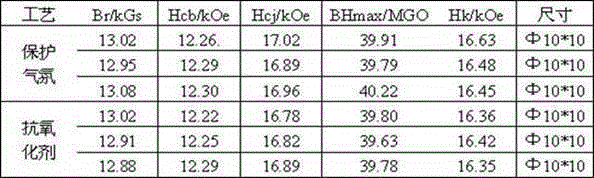

[0019] The sintered NdFeB magnet is prepared by the usual sintering method (protective atmosphere process), and the method is the same as in Example 1.

[0020] The method (antioxidant process) of the present invention is the same as the method for preparing sintered NdFeB by the usual sintering method, except that 5% of the antioxidant benzotriazole of the present invention and 95% of petroleum ether are added during jet milling. After jet milling, the powder mixing is carried out in a closed air atmosphere, and the compression molding is also carried out in an air atmosphere. The sintering adopts a low vacuum of 100 Pa, and the initial stage of sintering is controlled at a temperature of 300°C for 2.5 hours. Antioxidants are removed. Methods Three samples were prepared.

[0021] The magnetic properties of the NdFeB materials prepared by the above two methods were tested, and the results are shown in Table 2.

[0022] Table 2 Test results of magnetic properties of sintered N...

Embodiment 3

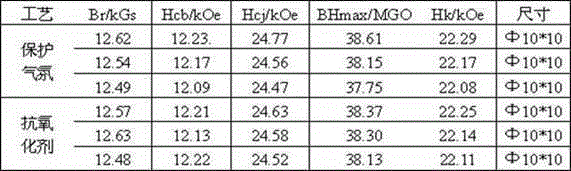

[0026] The sintered NdFeB magnet is prepared by the usual sintering method (protective atmosphere process), and the method is the same as in Example 1.

[0027] The method (antioxidant process) of the present invention is the same as the method for preparing sintered NdFeB by the usual sintering method, except that 0.05% of the antioxidant benzotriazole and 99.95% of petroleum ether of the present invention are added during jet milling. After jet milling, the powder mixing is carried out in a closed air atmosphere, and the compression molding is also carried out in an air atmosphere. The sintering adopts a low vacuum of 100 Pa, and the initial stage of sintering is controlled at a temperature of 300 ° C for 1.5 hours. The removal of antioxidants is carried out. Methods Three samples were prepared.

[0028] The magnetic properties of the NdFeB materials prepared by the above two methods were tested, and the results are shown in Table 3.

[0029] Table 3 Test results of magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com