Magnetized salient pole type mixed excitation synchronous motor

A hybrid excitation synchronous and salient pole technology, applied in the direction of synchronous machine, magnetic circuit shape/style/structure, electrical components, etc., can solve the problem that the rotor structure is difficult to unify the hybrid excitation motor, affect the sine of the magnetic field waveform, and the harmonic component of the magnetic field Increase and other problems, to avoid demagnetization effect, good symmetry, enhance the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

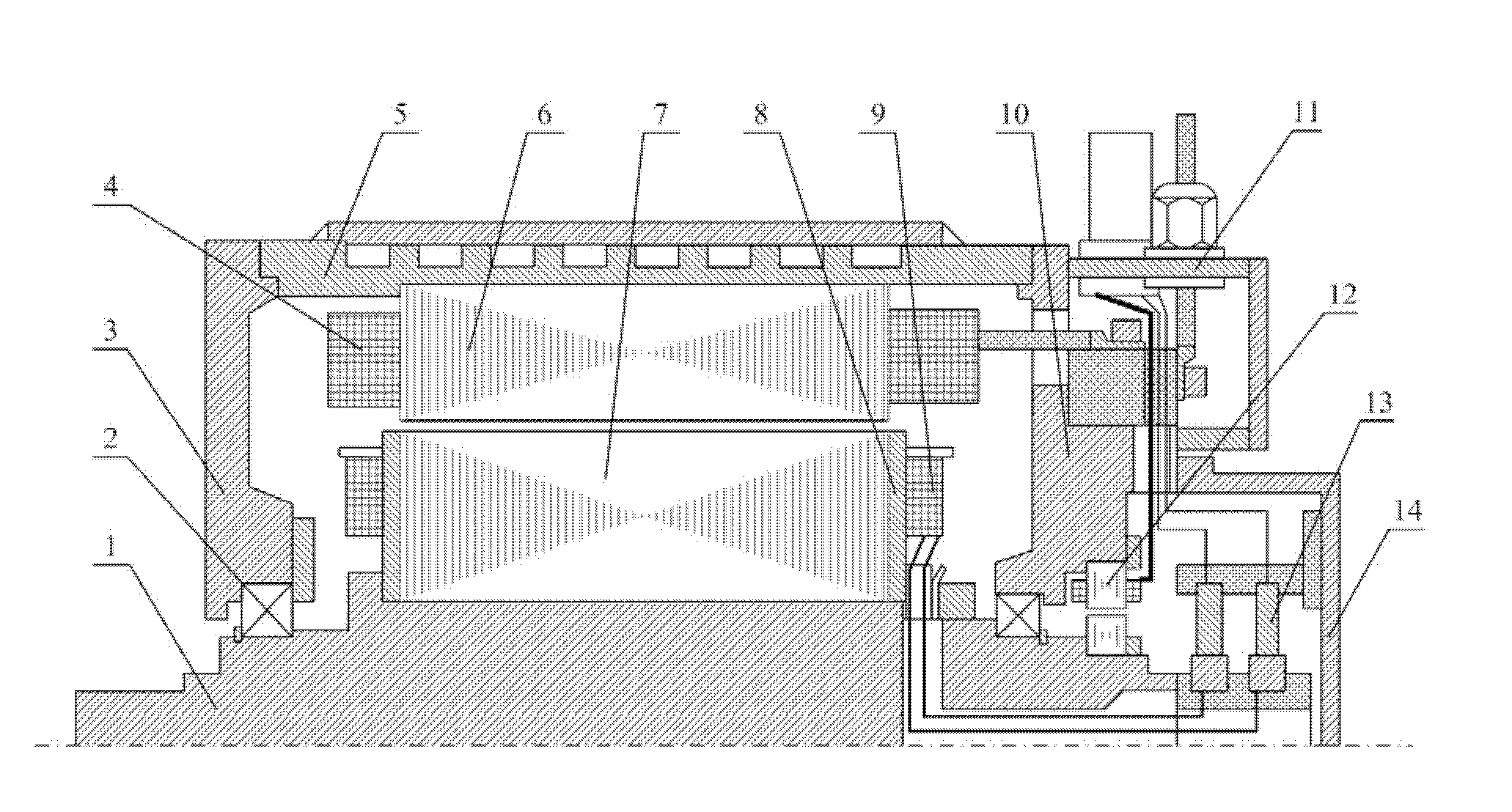

[0028] see figure 1 , figure 2 , the present invention magnetization type salient pole hybrid excitation synchronous motor, including shaft 1, bearing 2, front end cover 3, stator winding 4, casing 5, stator core 6, rotor core 7, permanent magnet steel 15, rotor pressure plate 8 , Electric excitation winding 9, rear end cap 10, junction box assembly 11, resolver 12, brush 13 and brush junction box 14.

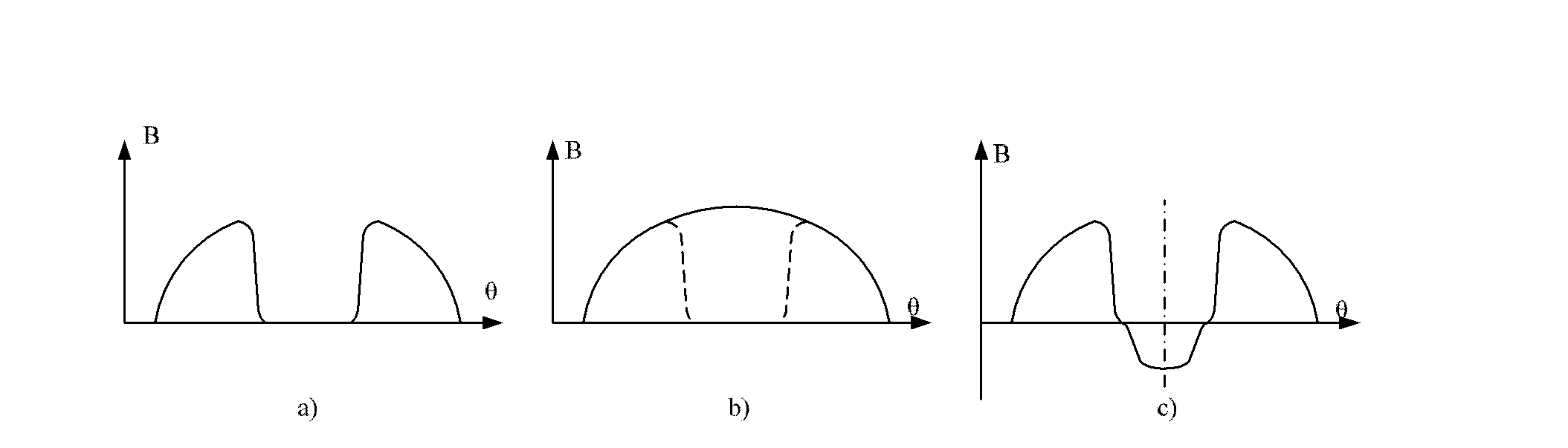

[0029] In the present invention, the stator core 6 and the stator winding 4 adopt a conventional permanent magnet synchronous motor stator structure; the rotor core 7 is similar to the rotor of a salient-pole electric excitation synchronous motor, has an electric excitation winding, and the air gap of the quadrature axis is greater than that of the direct axis .

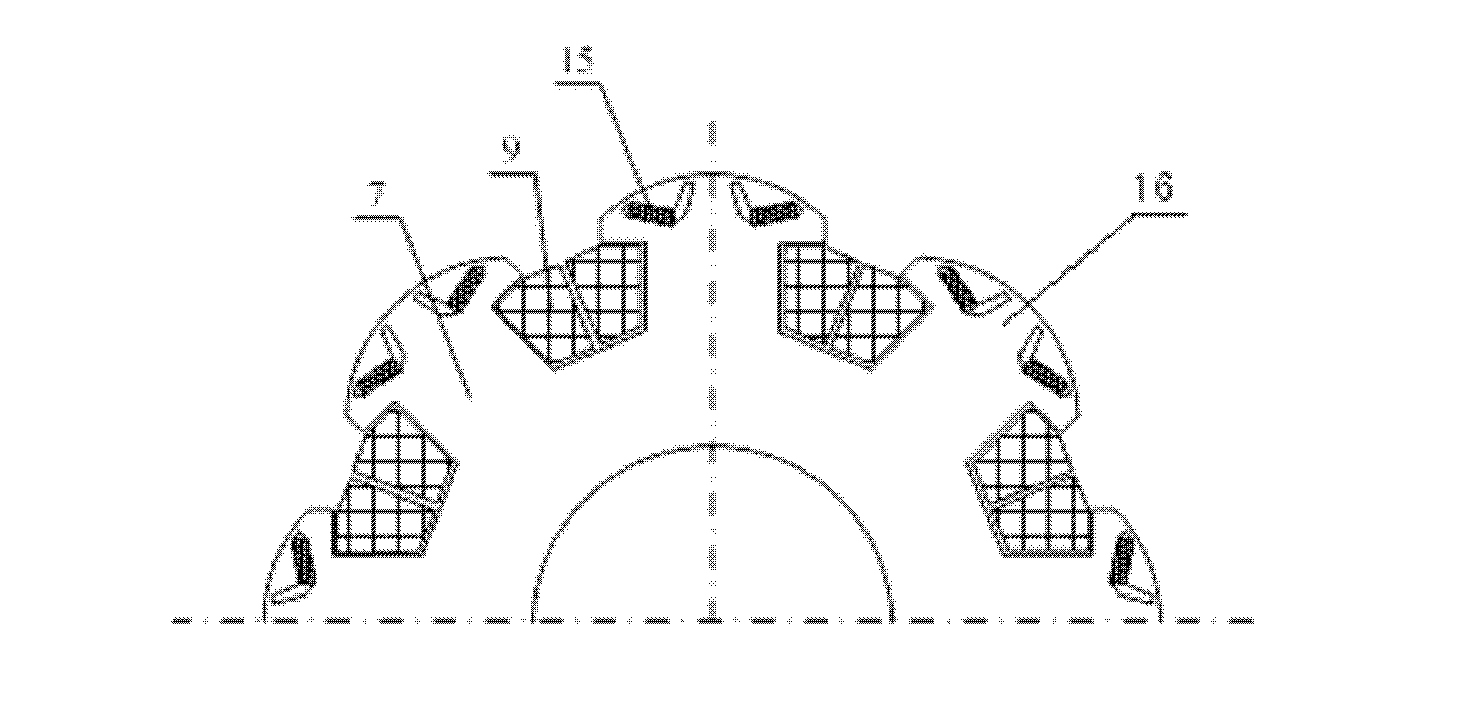

[0030] Each rotor magnetic pole of the rotor core 7 in the present invention is respectively designed with two "V"-shaped magnetic steel grooves, and magnetic steel 15 of the same polarity is respectively placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com