Composite film, method for producing a composite film and a film composite consisting of at least one composite film, and apparatus for producing a composite film

一种复合膜、封合的技术,应用在复合膜领域,能够解决焊缝强度不够等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

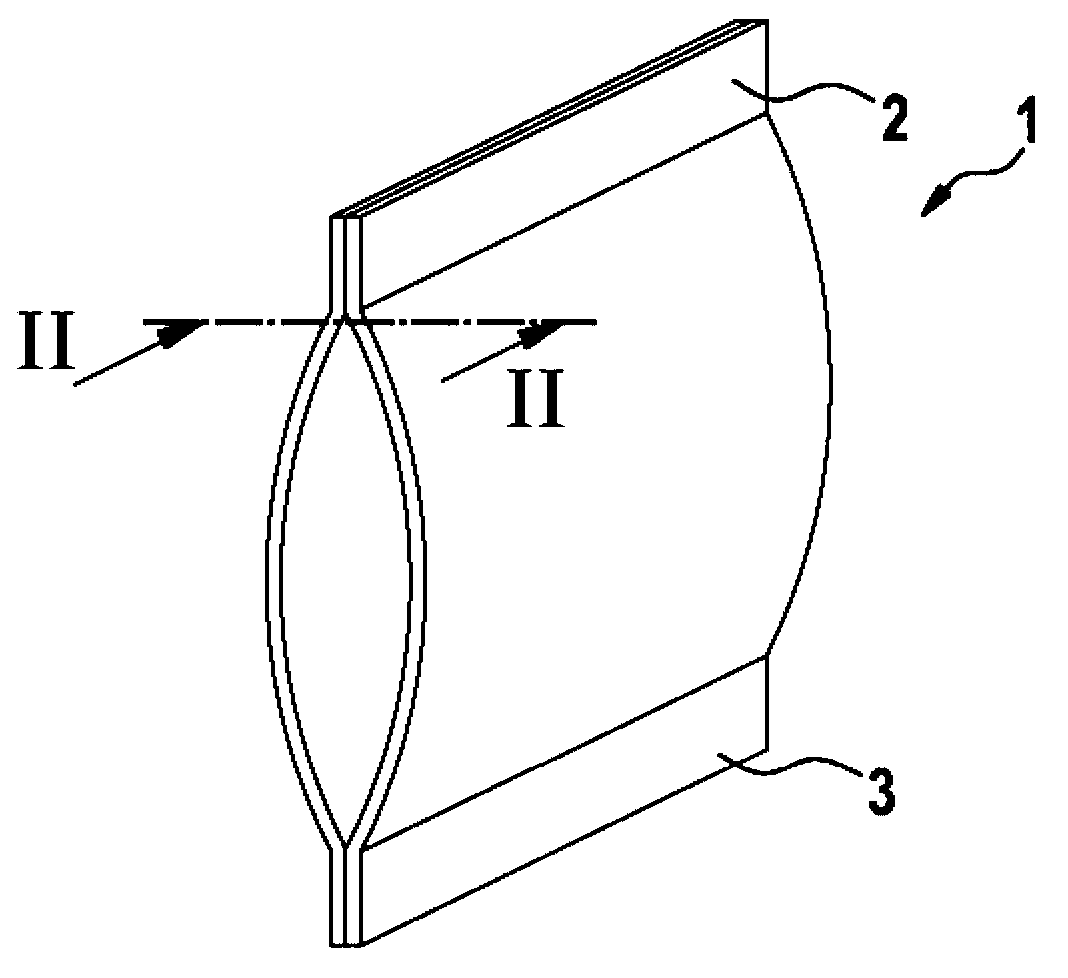

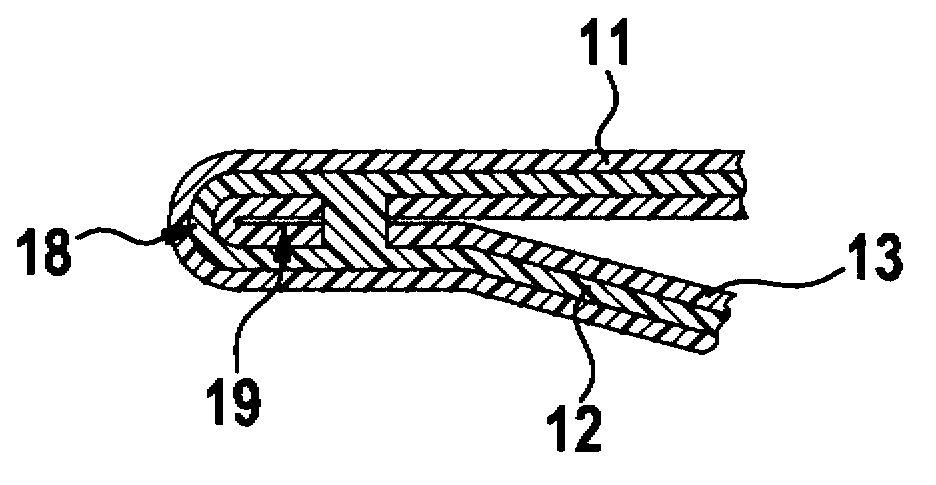

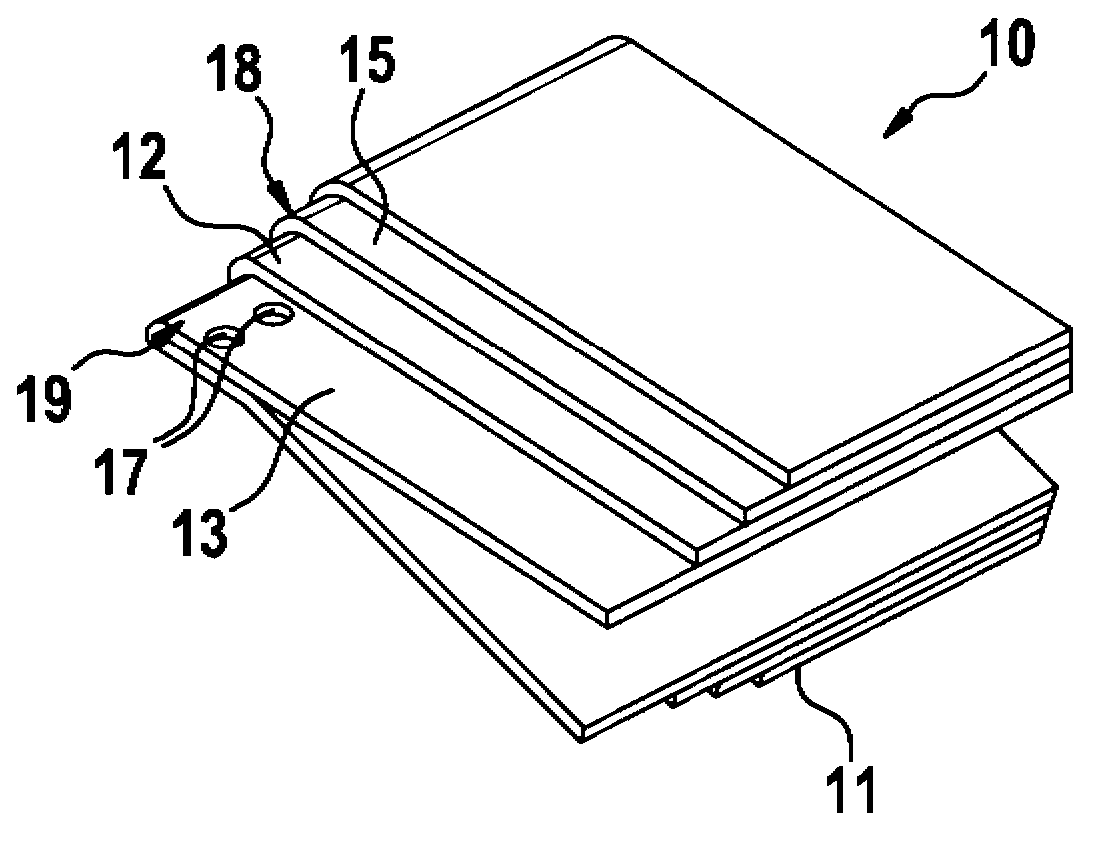

[0018] exist figure 1 A packaging 1 that can be used especially in food or the food industry is shown in . The packaging is used here in particular for packaging liquid, pasty or block fillings such as milk, water, ketchup or the like. It is particularly preferred to use the composite film to package food products that can be sensed by the sensor, such as water.

[0019] In this exemplary embodiment, the packaging 1 is designed in the shape of a pillow and has, in particular, a strip-shaped upper weld seam 2 and a likewise strip-shaped lower weld seam 3 . Such a package 1 is produced in practice by means of a so-called tube bag machine, in which at least one composite film stored as an endless strip of packaging material is drawn off, folded, filled and welded in a cyclical or continuous manner. Here such a tube bag machine works with a single packaging material web (in which two end regions spaced apart in the longitudinal direction relative to the preferred direction lie o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com