Greenhouse temperature control system

A temperature control system and greenhouse technology, applied in the agricultural field, can solve the problems of unsatisfactory cooling and environmental dry humidity, high operating costs and energy consumption, and inability to meet the special low temperature requirements of plants, so as to reduce long-term operating costs, The effect of reducing investment costs and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

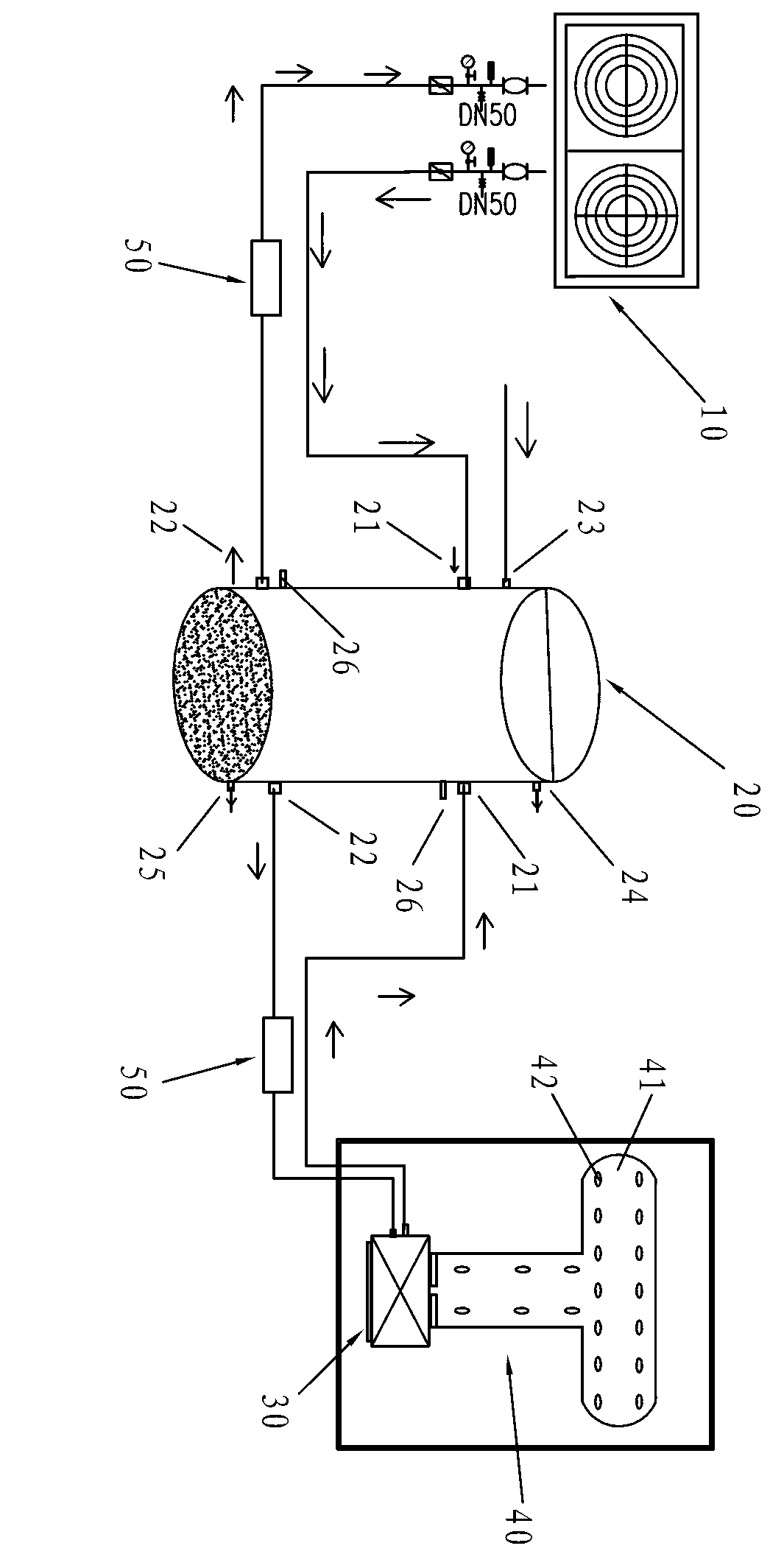

[0011] Such as figure 1 As shown, the greenhouse temperature control system of the present invention includes a cold and heat exchanger 10 , a dual-purpose thermal storage box 20 for hot and cold water, a hot and cold air circulation distribution machine 30 and an air supply and exhaust system 40 . A cold and hot circulating water pump 50 is arranged between the cold and hot water exchanger 10 and the dual-purpose heat preservation storage box 20 for cold and hot water. Circulating water pump 50, cold and heat exchanger 10 delivers cold water or hot water to cold and hot water dual-purpose insulation storage box 20 through cold and hot circulation water pump 50, and cold and hot water dual-purpose insulation storage box 20 supplies cold and hot water through cold and hot circulation water pump 50. The air circulation distribution machine 30 provides low temperature energy or heat energy, and the cold and hot air circulation distribution machine 30 discharges cold air or hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com