Composition for preventing or treating dentin-associated symptoms or diseases, and method using the same

A composition, dentin technology, applied in the direction of drug combination, phosphorus compound active ingredient, dentistry, etc., can solve the problem of unable to provide long-term efficacy, removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Synthesis of porous particles composed of silica

[0063] Add 1g (grams) of gelatin to 25g of deionized water, and place it in a constant temperature water tank at 40°C and stir for about 15 minutes until completely dissolved to form an aqueous gelatin solution.

[0064] Next, 4 g of sodium silicate was dissolved in 100 g of water, and placed in a constant temperature water bath at 40° C. and stirred for about 2 minutes to form an aqueous solution of sodium silicate.

[0065] On the other hand, add about 3.0mL (milliliter) of 6M sulfuric acid solution into 100g of water, and stir evenly to prepare an acidic aqueous solution with a pH value of about 1. Mix the aqueous sodium silicate solution with the acidic aqueous solution and adjust the pH to around 5. Next, let the sodium silicate mature for 3 minutes, then add the above-mentioned aqueous gelatin solution, place it in a constant temperature water bath at 40°C and stir for about 2 hours until the reaction ...

Embodiment 2

[0068] Example 2: Preparation of porous particles of silica containing calcium carbonate

[0069] Dissolve 0.09g of oxalic acid in 10g of deionized water, and then add 0.84g of calcium carbonate to form a first intermediate solution. Next, 10 g of alcohol was added to the first intermediate solution, and after stirring, 0.5 g of porous particles composed of silicon dioxide synthesized in Example 1 was added to form a second intermediate solution.

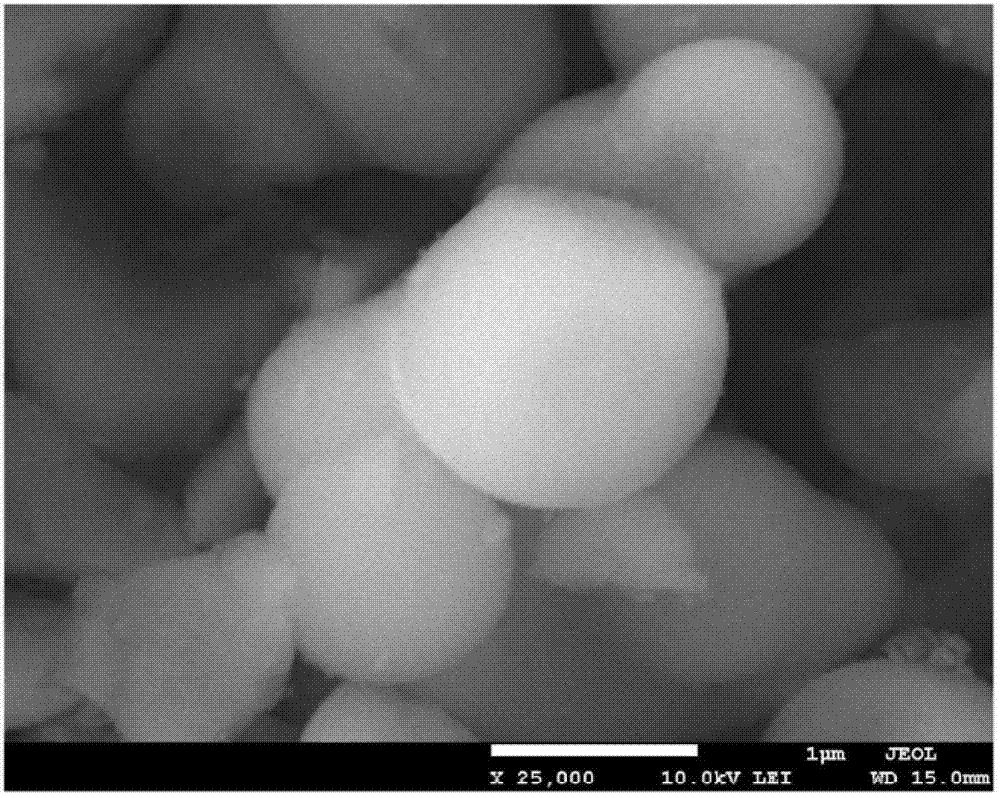

[0070] The above-mentioned second intermediate solution was stirred until dry, then put into an oven, and stood at 100° C. for one day. Next, put the product taken out from the oven into an air-filled high-temperature furnace, raise the temperature to 200 to 400° C., and keep the temperature for 5 hours. Finally, calcium carbonate-containing silica porous particles (hereinafter referred to as Ca-Si based porous particles (Ca-Si based porous particles)) are obtained. Such as figure 1 Shown is the SEM observation result of the calc...

Embodiment 3

[0072] Example 3: Preparation of preparations containing calcium-silica-based porous particles

[0073] 85.7% commercially available phosphoric acid (phosphoric acid, J.T. BAKER NALYZED, USA) was diluted with deionized water into a 31% phosphoric acid solution. Mix 0.05 g of the calcium-silicon-based porous particles obtained in Example 2 with 0.15 mL of a 31% phosphoric acid solution to prepare a porous particle preparation of silicon dioxide containing calcium carbonate (hereinafter referred to as CaCO 3 Porous SiO 2 preparation).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com