Suspended dry type low-intensity magnetic field magnetic separation equipment for fine-grained materials

A magnetic separation equipment and weak magnetic field technology, applied in the field of mineral processing engineering, can solve the problems of particle adhesion and entrainment, reduce the separation effect, environmental pollution, etc., and achieve the effect of reducing wrapping and entrainment, simple installation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

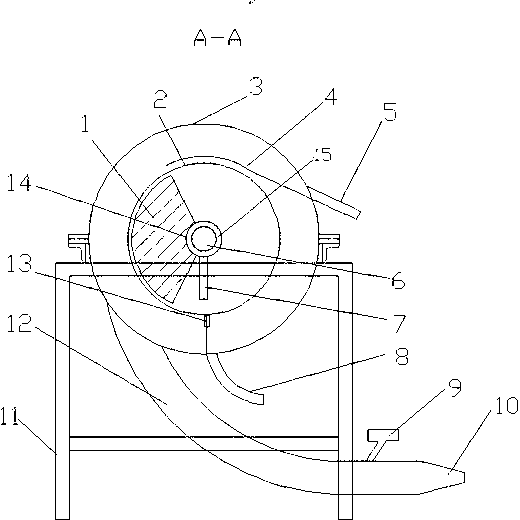

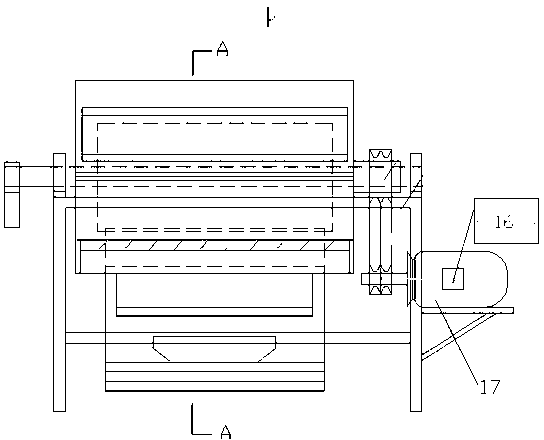

[0029] Such as figure 1 , 2 Shown: a dry weak magnetic field magnetic separation equipment for fine-grained materials consists of magnetic system 1, outer cylinder 2, inner cylinder 3, dividing plate 4, tailing outlet 5, support shaft 6, magnetic system declination adjustment handle 7 , Concentrate outlet 8, feed port 9, air flow interface 10, bracket 11, pipe 12, brush 13, ring 14, bearing 15, frequency converter 16, motor 17; motor 17 is connected to frequency converter 16, motor 17 The output shaft is connected with the support shaft 6; the support shaft 6 is connected with the support 11, the outer cylinder 2 is fixed on the support 11, the inner cylinder 3 is connected with the support shaft 6 and rotates with the support shaft 6; the support shaft 6 and the ring 14 The inner ring of the bearing 15 is matched with the support shaft 6, the outer ring of the bearing 15 is matched with the ring 14, the magnetic system 1 is fixed on the ring 14, and the ring 14 is connected wit...

Embodiment 2

[0038] Such as figure 1 , 2 Shown: a dry weak magnetic field magnetic separation equipment for fine-grained materials consists of magnetic system 1, outer cylinder 2, inner cylinder 3, dividing plate 4, tailing outlet 5, support shaft 6, magnetic system declination adjustment handle 7 , Concentrate outlet 8, feed port 9, air flow interface 10, bracket 11, pipe 12, brush 13, ring 14, bearing 15, frequency converter 16, motor 17; motor 17 is connected to frequency converter 16, motor 17 The output shaft is connected with the support shaft 6; the support shaft 6 is connected with the support 11, the outer cylinder 2 is fixed on the support 11, the inner cylinder 3 is connected with the support shaft 6 and rotates with the support shaft 6; the support shaft 6 and the ring 14 The inner ring of the bearing 15 is matched with the support shaft 6, the outer ring of the bearing 15 is matched with the ring 14, the magnetic system 1 is fixed on the ring 14, and the ring 14 is connected wit...

Embodiment 3

[0047] Such as figure 1 , 2 Shown: a dry weak magnetic field magnetic separation equipment for fine-grained materials consists of magnetic system 1, outer cylinder 2, inner cylinder 3, dividing plate 4, tailing outlet 5, support shaft 6, magnetic system declination adjustment handle 7 , Concentrate outlet 8, feed port 9, air flow interface 10, bracket 11, pipe 12, brush 13, ring 14, bearing 15, frequency converter 16, motor 17; motor 17 is connected to frequency converter 16, motor 17 The output shaft is connected with the support shaft 6; the support shaft 6 is connected with the support 11, the outer cylinder 2 is fixed on the support 11, the inner cylinder 3 is connected with the support shaft 6 and rotates with the support shaft 6; the support shaft 6 and the ring 14 The inner ring of the bearing 15 is matched with the support shaft 6, the outer ring of the bearing 15 is matched with the ring 14, the magnetic system 1 is fixed on the ring 14, and the ring 14 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com