Welding process for crankshaft counter balance of internal combustion locomotive engine

A technology for diesel locomotives and welding processes, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as flaw detection errors, crankshaft deformation, etc., and achieve the effect of expanding space and high starting point of welding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment includes the following steps:

[0056] 1) Design welding groove:

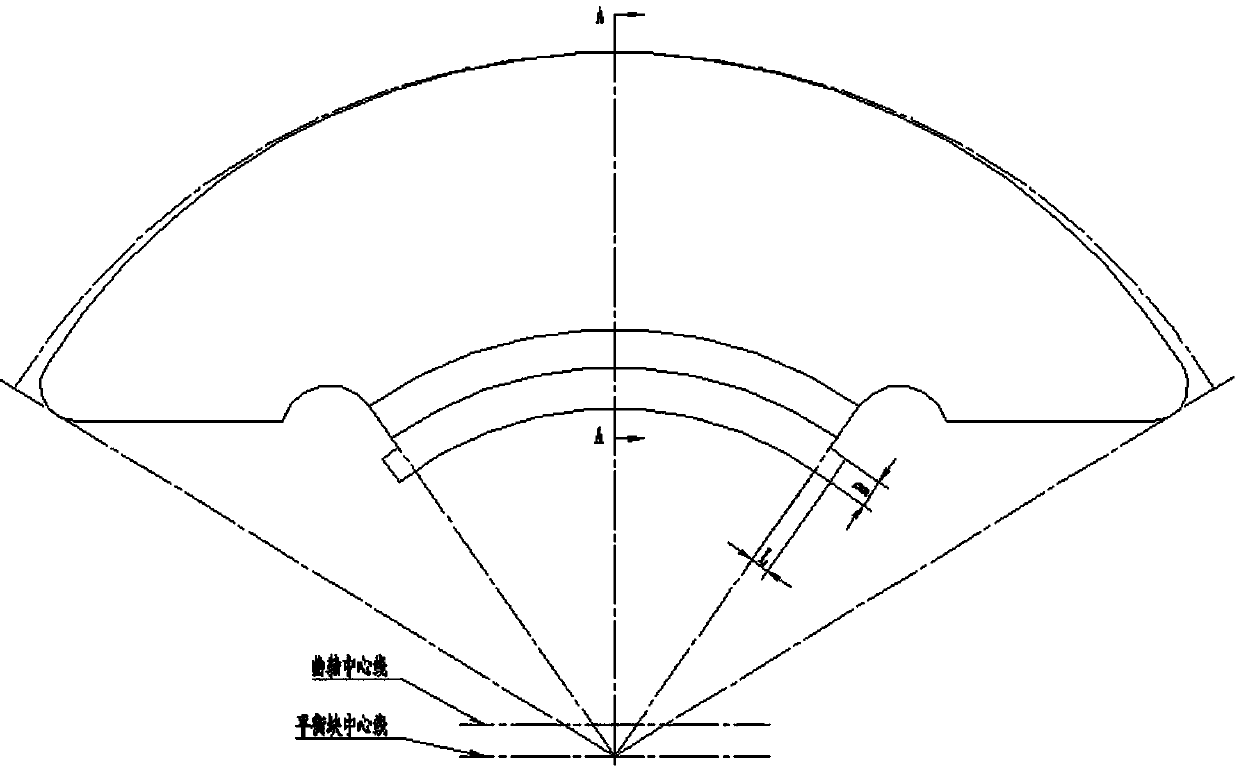

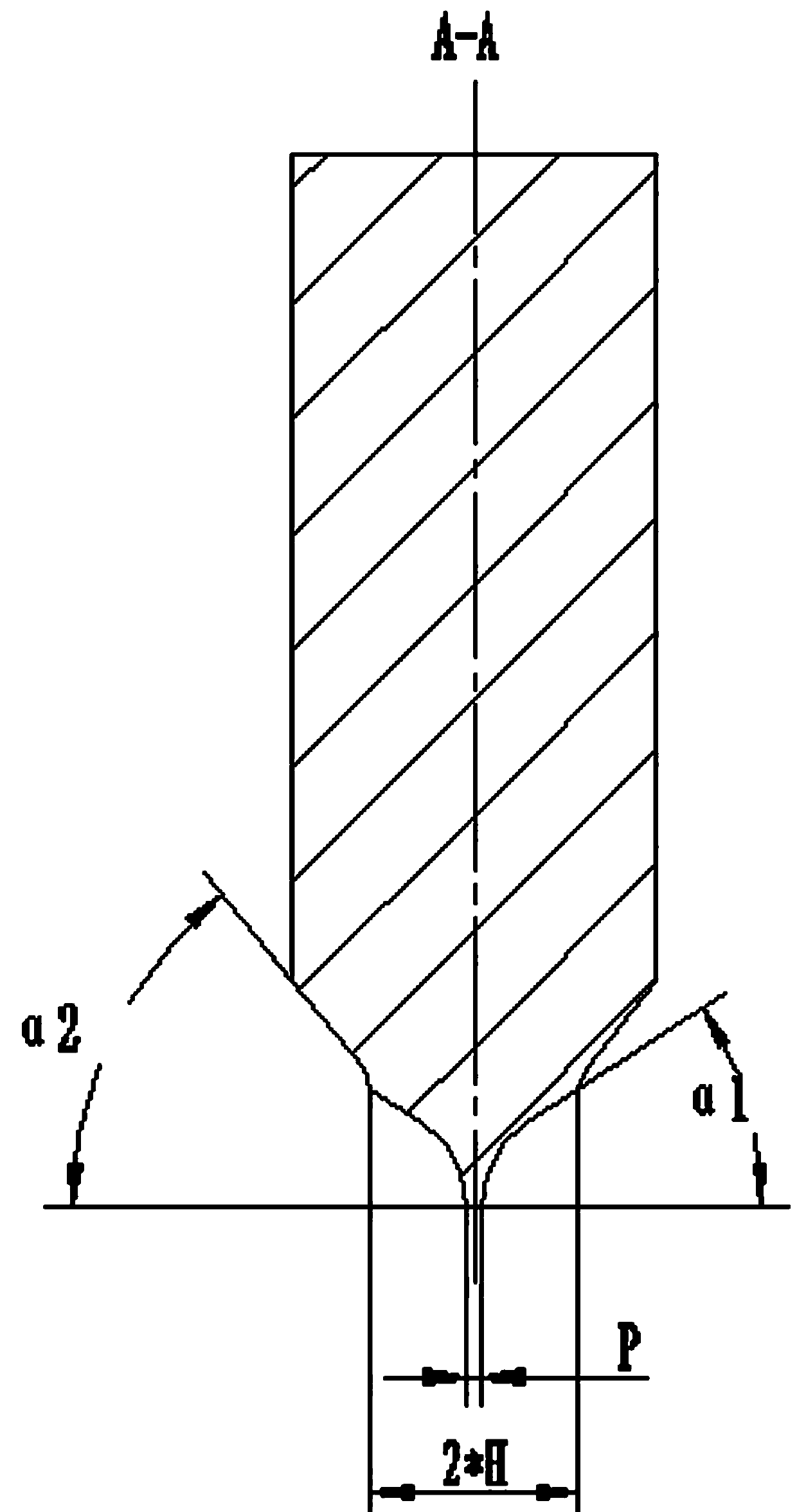

[0057] The groove of the balance weight adopts a groove form with blunt edges and double J+V: root R=15mm, groove surface angle α 1 =35°、α 2 =50°, H=20mm, the thickness of the blunt edge p=3mm; the arc start and stop ends with L=10mm and width B=15mm are processed in the same size at both ends of the balance weight;

[0058] 2) Preheating:

[0059] Enter the heating furnace to preheat the whole to 330°C, keep it for 1.5 hours, and immediately weld the tires after the furnace is released;

[0060] 3) Formal welding:

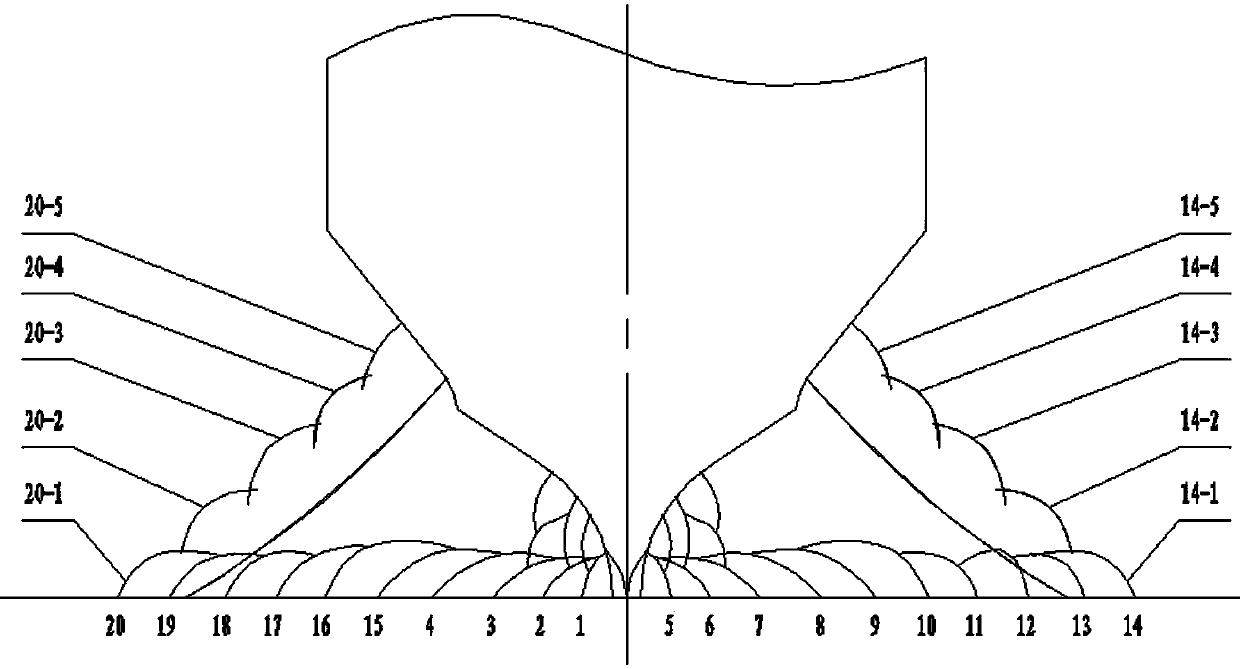

[0061] The balance weight is assembled symmetrically along the crankshaft axial and circumferential direction, and the balance weight assembly gap is 1~2mm; The MAG welding method of G4Si1 / ER50-6 welding wire, two people weld the balance weight symmetrically at the same time; welding current ≯300A, welding voltage ≯34V; multi-layer multi-pass welding, single-pass welding requirements: ...

Embodiment 2

[0069] This embodiment includes the following steps:

[0070] 1) Design welding groove:

[0071] The bevel of the balance weight process adopts a bevel form with blunt edges and double J+V: root R=25mm, bevel surface angle α 1 =25°、α 2 =55°, H=25mm, the thickness of the blunt edge p=4mm; the arc start and stop ends with L=15mm and width B=20mm are processed in the same size at both ends of the balance weight;

[0072] 2) Preheating:

[0073] Enter the heating furnace to preheat the whole to 350°C, keep it for 1.5 hours, and immediately weld the tires after being out of the furnace;

[0074] 3) Formal welding:

[0075] The balance weight is assembled symmetrically along the crankshaft axial and circumferential direction, and the balance weight assembly gap is 1~2mm; MAG welding method of G4Si1 / ER50-6 welding wire, two people weld balance weights symmetrically at the same time; welding current ≯300A, welding voltage ≯34V; multi-layer multi-pass welding, single-pass welding seam requiremen...

Embodiment 3

[0083] This embodiment includes the following steps:

[0084] 1) Design welding groove:

[0085] The groove of the balance weight adopts a groove form with blunt edges and double J+V: root R=23mm, groove surface angle α 1 =30°、α 2 =52°, H=23mm, the thickness of the blunt edge p=4mm; the arc start and stop ends with L=15mm and width B=18mm are processed in the same size at both ends of the balance weight;

[0086] 2) Preheating:

[0087] Enter the heating furnace to preheat the whole to 300℃, keep it for 2 hours, and immediately put the tire on welding after being out of the furnace;

[0088] 3) Formal welding:

[0089] The balance weight is assembled symmetrically along the crankshaft axial and circumferential direction, and the balance weight assembly gap is 1~2mm; MAG welding method of G4Si1 / ER50-6 welding wire, two people weld balance weights symmetrically at the same time; welding current ≯300A, welding voltage ≯34V; multi-layer multi-pass welding, single-pass welding seam requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com