Method for adding vertical type leaf filter filtration aid

A filter aid and leaf filter technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of shortened production cycle of leaf filter, high loss of alumina, low capacity utilization rate, etc., and achieve extended Normal filter time, improved effect, enhanced bridging effect

Active Publication Date: 2013-04-03

SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the above-mentioned technical problems, the present invention provides a method for adding a filter aid to a vertical leaf filter, the purpose of which is to solve the problems of large consumption of lime milk, high loss of alumina, shortened production cycle of leaf filter, and low utilization rate of production capacity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

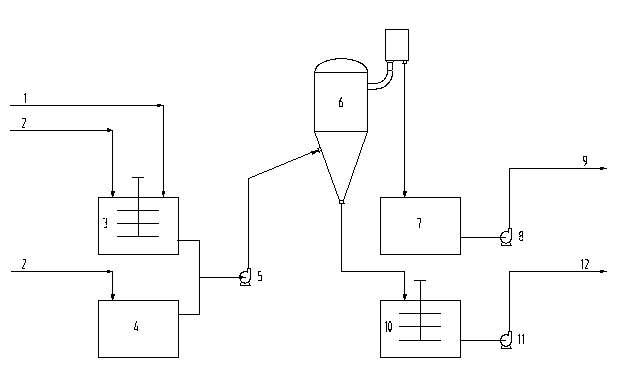

The invention relates to a method for adding a vertical type leaf filter filtration aid. The method comprises the following steps of: mixing lime milk with a crude liquid or refined liquid in a filtration aid preparation tank in advance to fully stir to generate 3CaO.Al2O3.6H2O as the filtration aid for later use; feeding the prepared filtration aid to hang a cloth through a leaf filter feeding pump during a cloth hanging step of the leaf filter; feeding from a crude liquid groove in a normal filtering step to ensure that the filtered refined liquid is subjected to a subsequent procedure through a refined liquid groove; performing settling separation, washing or pre-desilicication on a filter cake by red mud to finish once operation; and carrying out a new round of circular working period. The method has the advantages and the effects that the addition amount of the filtration aid is greatly reduced, the consumption amount of the lime milk is indirectly reduced, the loss of aluminum oxide is also reduced, the coating effect also can be improved, a bridging function of the filtration aid is intensified, the normal filtering time is prolonged, the speed is low when the resistance of the filter cake is increased in the same filtering period, and the power consumption of the feeding pump is greatly reduced.

Description

technical field [0001] The invention relates to a method for adding a filter aid, in particular to a method for adding a filter aid to a vertical leaf filter during alumina production, and belongs to the technical field of alumina production. Background technique [0002] In the process of alumina production, the ore is ground and eluted, and the obtained eluate is diluted and separated by sedimentation to obtain a crude liquid. The crude liquid must be filtered through a leaf filter to remove floating matter (red mud particles, etc.) ), the qualified semen is obtained and enters the decomposition and roasting process to complete the alumina production process. The main equipment in the fine filtration process of sodium aluminate solution is the traditional Kelly leaf filter and the vertical leaf filter; ≤250mg / L) mixed with the prepared milk of lime in the crude liquid tank, sent to the corresponding leaf filter by the feeding pump for fine filtration, and the output of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01F7/02B01D37/02

Inventor 李志国石建军

Owner SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com