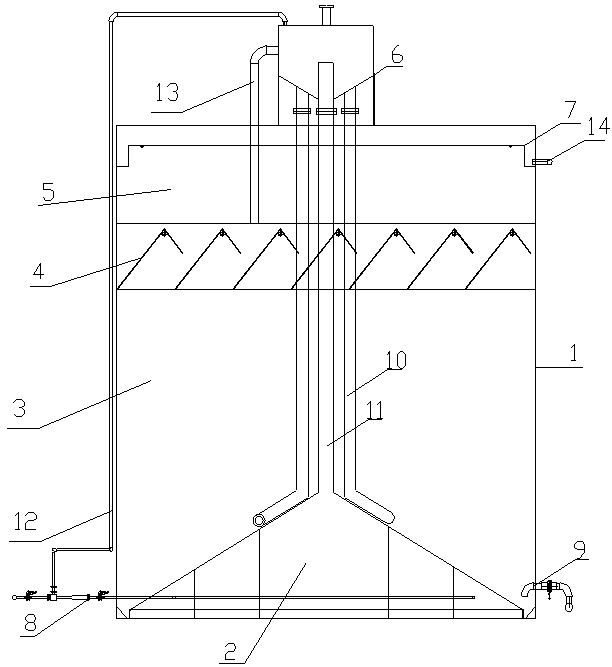

Internal-mixing anaerobic reaction tank

A tank body and gas-water separation tank technology, applied in the field of anaerobic reaction, can solve the problems of inability to apply high-concentration water quality and biochemical, slow growth of granular sludge, easy loss of anaerobic sludge, etc., and achieve the pH value of influent water. The effect of loose requirements, easy operation and low tank height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0017] UASB (Upflow Anaerobic Sludge Bed Reactor) with a diameter of 5.72*7.5 meters and the internal mixed anaerobic reaction tank of the present invention (utility model) with the same height-to-diameter ratio are used to treat sewage. The water quality and load conditions are as follows:

[0018] UASB: Influent COD 12000mg / l, effluent 3600mg / l, removal rate 70%, ph value 5, need to add alkali to adjust ph value to 7, water volume 160m3 / d, volume load 7.5kg / m3.d.

[0019] Internal mixing anaerobic reaction tank: Influent COD 12000mg / l, effluent 400-600mg / l, removal rate 95%, pH value 5, no need to add or subtract adjustment, treated water volume 160m3 / d, volume load reached 10.2kg / m3. d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com