High performance nano-composite aluminum oxide based self-lubricating cutter material and preparation method thereof

A technology of compounding alumina and tool materials, applied in the field of cutting tool materials, can solve the problems of difficulty in taking into account mechanical properties and friction properties, achieve good application prospects, optimize mechanical properties, high mechanical properties and friction and wear properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Technical scheme of the present invention is as follows:

[0007] A high-performance nano-composite alumina-based self-lubricating tool material, the volume percentage of raw materials is as follows:

[0008] Titanium carbide 25-55%; Nano calcium fluoride 5-15%; Magnesium oxide 0.5-1.5%; Aluminum oxide balance;

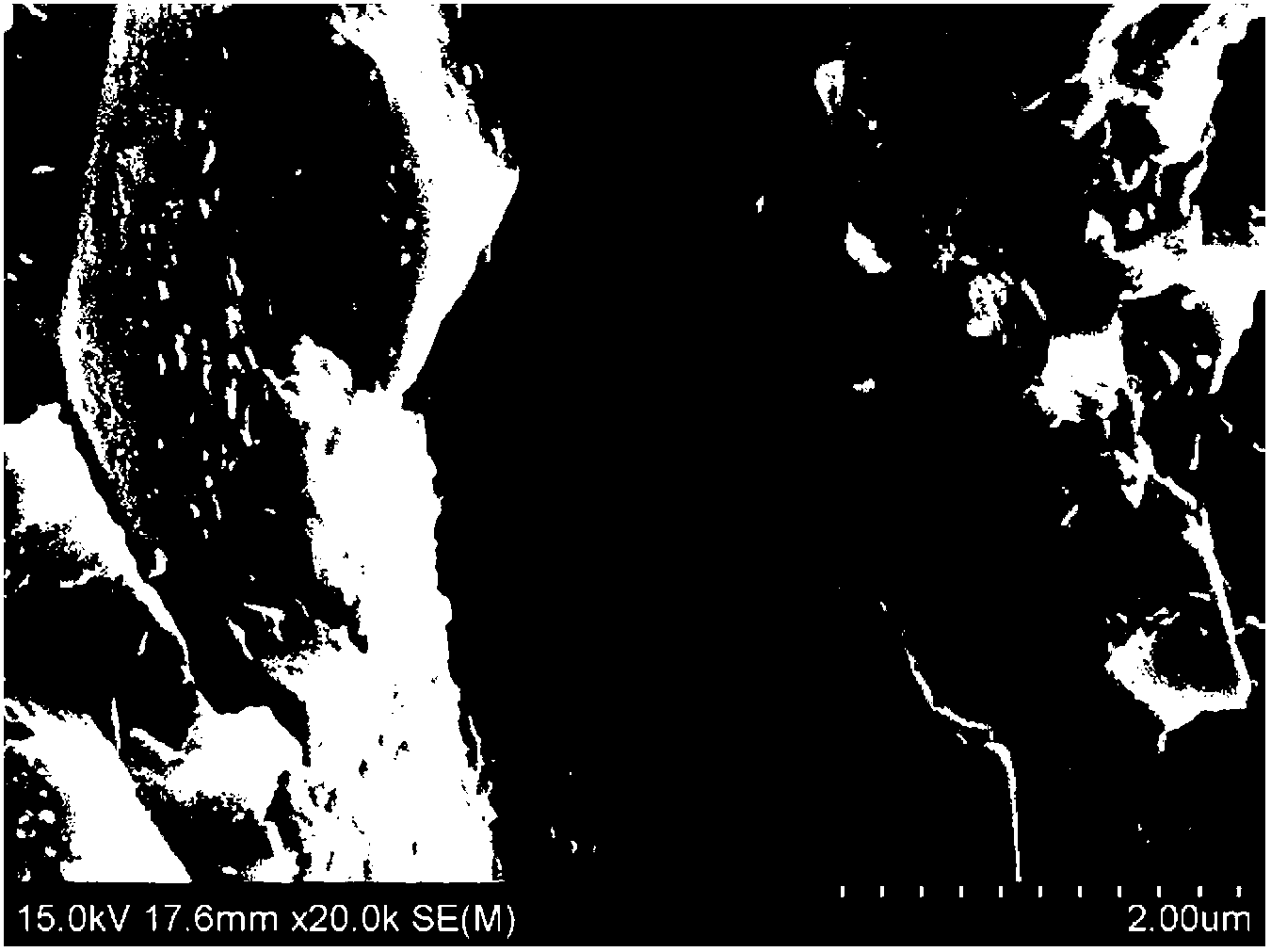

[0009] The micron-sized alumina powder is ball-milled to an average particle size of 1-2 μm;

[0010] The titanium carbide is a micron-sized powder, which is ball-milled to an average particle size of 1-2 μm;

[0011] The particle size range of the nanometer calcium fluoride is 15-50nm.

[0012] Preferably according to the present invention, the high-performance nano-composite alumina-based self-lubricating tool material has a volume percentage composition of raw materials as follows:

[0013] Aluminum oxide 40-55%; titanium carbide 30-50%; nano-calcium fluoride 5-15%; magnesium oxide 0.5-1%.

[0014] Preferably according to the present invention, the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com