Preparation method of prenyl acetate

A kind of ritol ester and alcohol ester technology, applied in the field of ritol ester preparation, can solve the problems of increasing solvent recovery, high price, reducing production capacity, etc., and achieves simple preparation reaction conditions, improved equipment utilization, and high product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Reaction molar ratio Acetic anhydride: Pentadienol: Sodium acetate=1:1.8.:0.05.

[0019] 1) Make sure the reactor is clean and dry. Put 1020 kg of acetic anhydride into the reaction kettle with a pump and add 41 kg of sodium acetate. After heating up to 100°C, add 1548 kg of pentadienol dropwise at 100-110°C. After about 4 hours of dripping, at this temperature Constant temperature reaction for 2 hours; reaction end point: the content of pentadienol in the feed liquid is less than 0.5%.

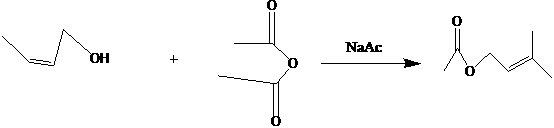

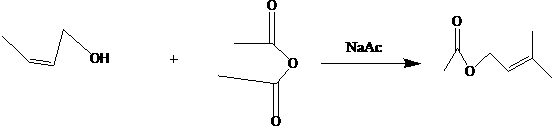

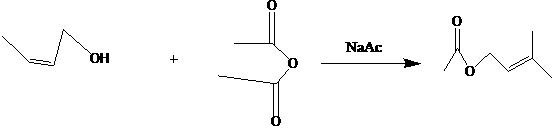

[0020] Reaction equation:

[0021]

[0022] 2) After the reaction, add 260 kg of water to the crude product, stir and let it stand. The lower layer of water is divided to obtain 2420 kilograms of crude pitol ester liquid. Add anhydrous sodium carbonate to the crude pitol ester liquid to adjust Ph to 7.

[0023] 3) Adjust the Ph to 7 in step (2) and carry out rectification of the crude pitol ester liquid, collect the fraction at 70-80°C / 50mmHg to be the finished pitol ester, and ...

Embodiment 2

[0025] Reaction molar ratio Acetic anhydride: Pentadienol: Sodium acetate=1:1.9.:0.05.

[0026] 1) Make sure the reactor is clean and dry. Put 1020 kg of acetic anhydride into the reaction kettle with a pump and add 41 kg of sodium acetate. After heating up to 100°C, add 1634 kg of pentadienol dropwise at 100-110°C. After about 4 hours of dripping, at this temperature Constant temperature reaction for 2 hours; reaction end point: the content of pentadienol in the feed liquid is less than 0.5%.

[0027] Reaction equation:

[0028]

[0029] 2) After the reaction, add 280 kg of water to the crude product, stir and let stand. The lower layer of water is divided to obtain 2430 kilograms of crude pitol ester liquid. Add anhydrous sodium carbonate to the crude pitol ester liquid to adjust Ph to 7.

[0030] 3) After adjusting the Ph to 7 in step 2), carry out rectification of the crude pitol ester liquid, collect the distillate at 70-80°C / 50mmHg, which is the finished pear alco...

Embodiment 3

[0032] Reaction molar ratio Acetic anhydride: Pentadienol: Sodium acetate=1:1.7:0.05.

[0033] 1) Make sure the reactor is clean and dry. Put 1020 kg of acetic anhydride into the reaction kettle with a pump and add 41 kg of sodium acetate. After heating up to 100°C, add 1462 kg of pentadienol dropwise at 100-110°C. After about 4 hours of dripping, at this temperature Constant temperature reaction for 2 hours; reaction end point: the content of pentadienol in the feed liquid is less than 0.5%.

[0034] Reaction equation:

[0035]

[0036] 2) After the reaction, add 260 kg of water to the crude product, stir and let it stand. The lower layer of water is divided to obtain 2180 kilograms of crude pitol ester liquid. Add anhydrous sodium carbonate to the crude pitol ester liquid to adjust Ph to 7.

[0037] 3) Adjust the Ph to 7 in step (2) and carry out rectification of the crude pitol ester liquid, collect the fraction at 70-80°C / 50mmHg to be the finished pitol ester, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com