Color gel coat for sanitary ware and preparation method thereof

A technology for sanitary ware and gel coat, which is applied in the field of colored gel coat for sanitary ware and its preparation, can solve the problems of difficult production, difficult to control the gel solidification time, etc., and achieves the effect of ensuring water resistance, rich colors and good surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0019] The colored gel coat of the sanitary ware of the present embodiment is ivory white, and it is made by the component of following parts by weight:

[0020] 100 parts of matrix resin; among them, 90 parts of medium-active matrix resin, whose molecular weight distribution index (Mw / Mn) ≤ 2.5, specifically adopts the m-phenylene neopentyl glycol type matrix resin of Huari Company's model 251, in which unsaturated di The number of moles of basic acid is 50% of the total number of moles of dibasic acid; 10 parts of highly active matrix resin, its molecular weight distribution index (Mw / Mn) ≤ 2.5, the specific use of Huari company's model is 230 isophthalic new Pentylene glycol-based matrix resin, in which the mole number of unsaturated dibasic acid is 70% of the total mole number of dibasic acid.

[0021] 12 parts of styrene.

[0022] 20 parts of talcum powder.

[0023] Fumed silica 2 parts.

[0024] 0.15 part of thixotropic stabilizer, what adopt is the PR600 type thixotr...

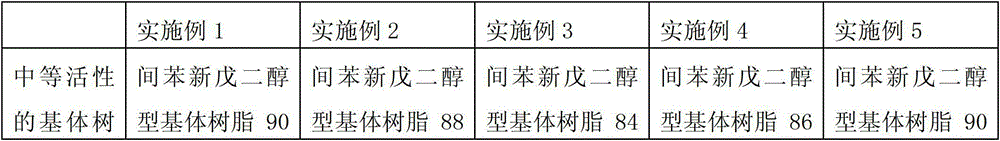

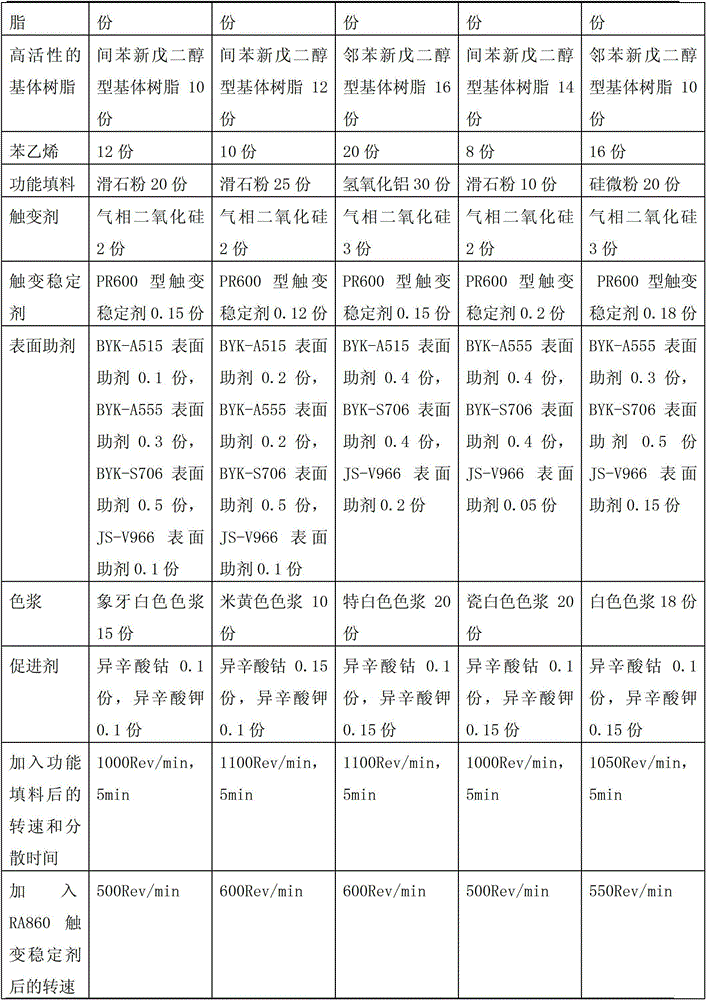

Embodiment 2~ Embodiment 5)

[0033] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0034]

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com