System and technology for purifying cold water by methane

A technology of chilled water system and biogas, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of water chiller consumption, increase operating cost, large energy, etc., and achieve the effect of saving operating cost, reducing operating cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

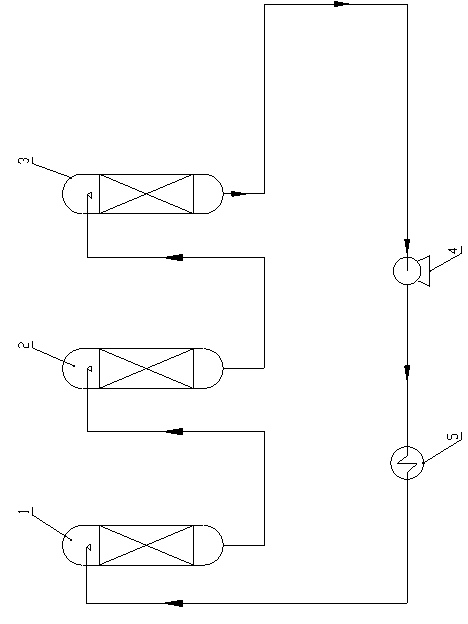

Method used

Image

Examples

Embodiment Construction

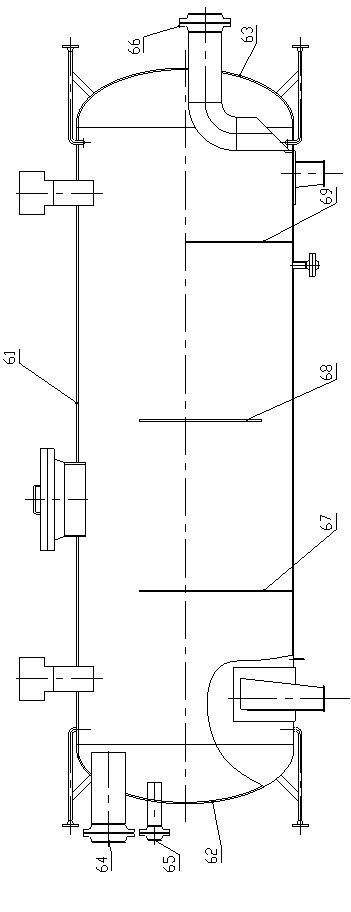

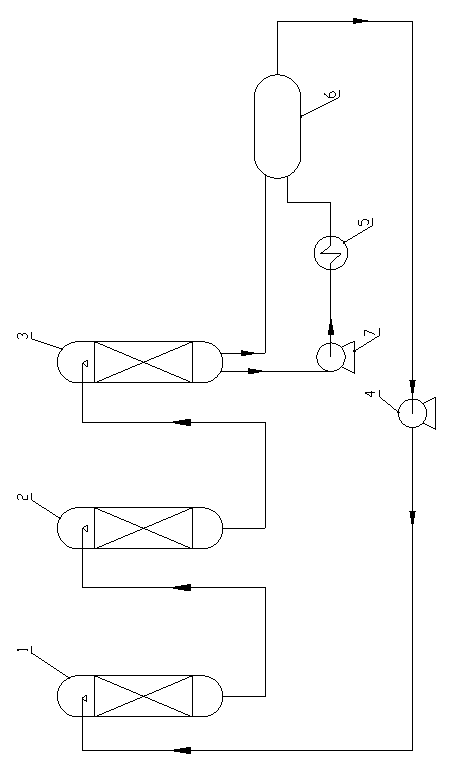

[0033] Such as figure 2 Shown, the present invention comprises absorption tower 1, first-level desorption tower 2, secondary desorption tower 3 that are connected successively by pipeline, also includes cold water tank 6, circulating water pump 7, water chiller 5, secondary desorption tower 3 lower sides are arranged There are two water outlets; the left side of the cold water tank 6 is provided with a normal temperature process water pipe port 64 and a low temperature process water pipe port 65, and the right side of the cold water tank 6 is provided with a water outlet port. One of the water outlets of the secondary desorption tower 3 is connected to the low-temperature process water pipe port 65 of the circulating water pump 7, the chiller 5 and the cold water tank 6 through a pipeline, and the other water outlet of the secondary desorption tower 3 is directly connected to the cold water tank through a pipeline. The normal temperature process water nozzle 64 of 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com