Method for improving laser plasma shock wave pressure through magnetic and electric fields

A laser plasma and shock wave technology, which is applied in the field of surface engineering technology and laser processing, can solve the problems that the flow rate, uniformity and thickness of the water confinement layer are difficult to guarantee, and affect the quality of strengthening, so as to make up for the instability of the water curtain and the stability of the confinement effect , to apply a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

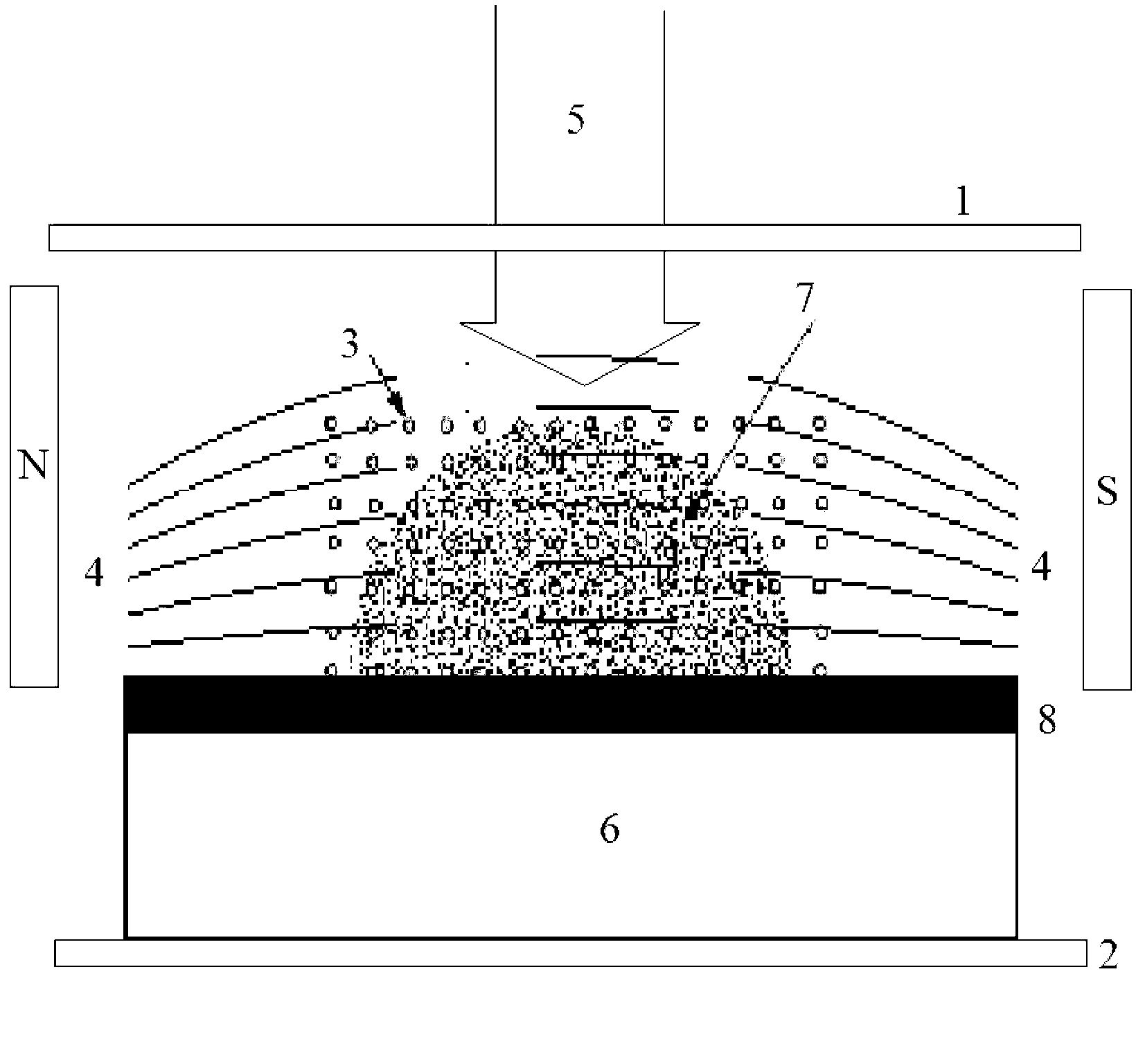

[0019] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0020] The invention adopts the magnetic field and the water confinement layer to constrain the expansion of the plasma to increase the shock wave pressure. The principle of laser plasma generation is: after the strong laser is focused by the lens in the air, when the energy density of the beam exceeds the air breakdown threshold, under the action of the strong electric field of the laser beam, the gas is ionized and strongly absorbs the laser, and the pressure rises sharply at the same time. High and volume expansion, a small-scale explosion occurs. This phenomenon is called optical breakdown. It is generally believed that light breakdown first occurs at the focal point. There are very few free electrons naturally present in the ambient gas, and the ionization potential is so high that it is difficult for a single photon to ionize the gas. It is generally belie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com