Double-tank method for continuously plating thick gold with cyanide-free chemical gold plating solutions

A technology of chemical gold plating and cyanide chemistry, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of easy contamination of plating solution, chemical gold plating solution containing cyanide, etc., to achieve good bonding force, The appearance is golden yellow, the crystal is fine and dense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

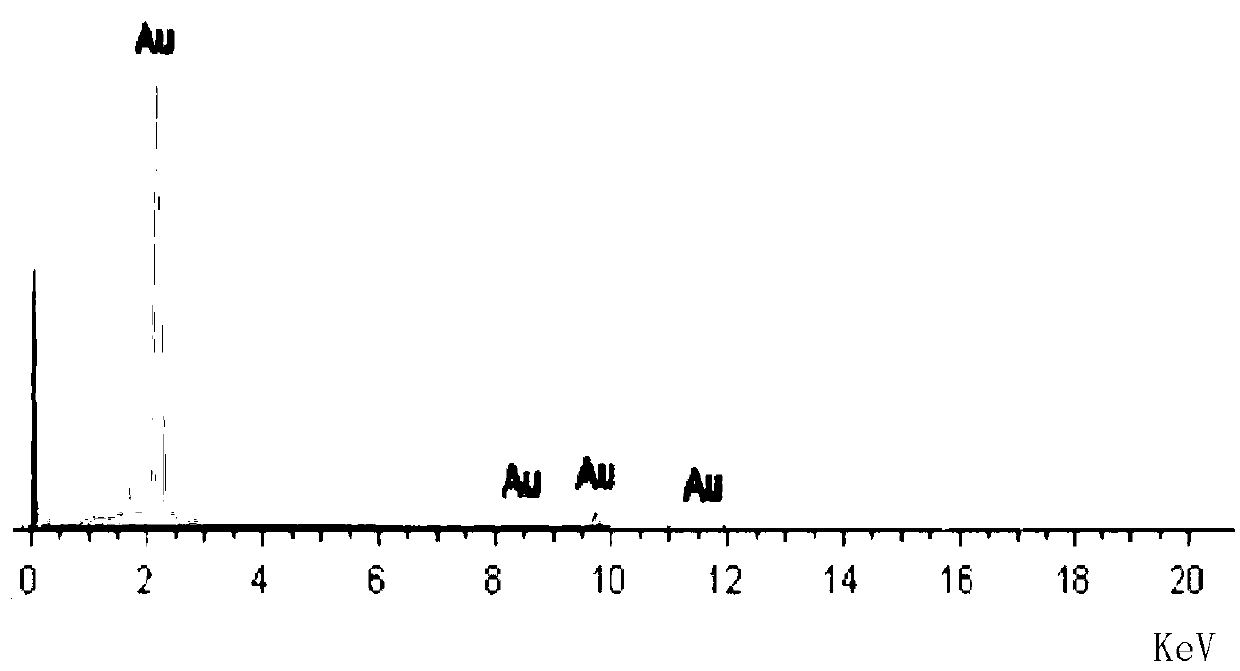

Image

Examples

Embodiment Construction

[0045] In the following examples, copper sheets are used as the base material, and the process flow for the application of cyanide-free chemical gold plating solution is: ultrasonic degreasing (50-70°C, time 3-5min) → water washing → pickling (sulfuric acid 30ml / L, 20-40s) →Water washing→Deionized water washing→Displacement gold plating→Water washing→Deionized water washing→Reduction chemical gold plating.

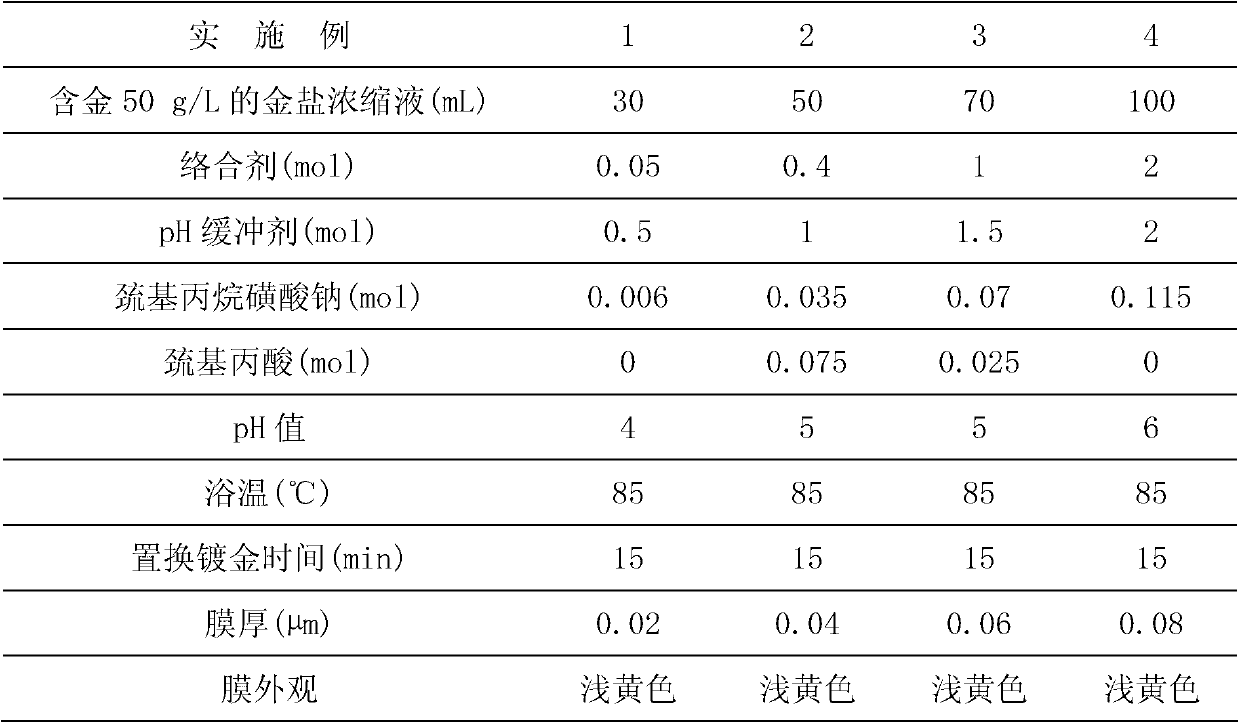

[0046] In the application process of the cyanide-free chemical gold-plating solution in Examples 1-4, the raw materials, conditions and some experimental results adopted for the displacement gold-plating and reduction-type chemical gold-plating are shown in Table 1 and Table 2 respectively.

[0047] Table 1 Preparation of 5L Displacement Gold Plating Solution Meter

[0048]

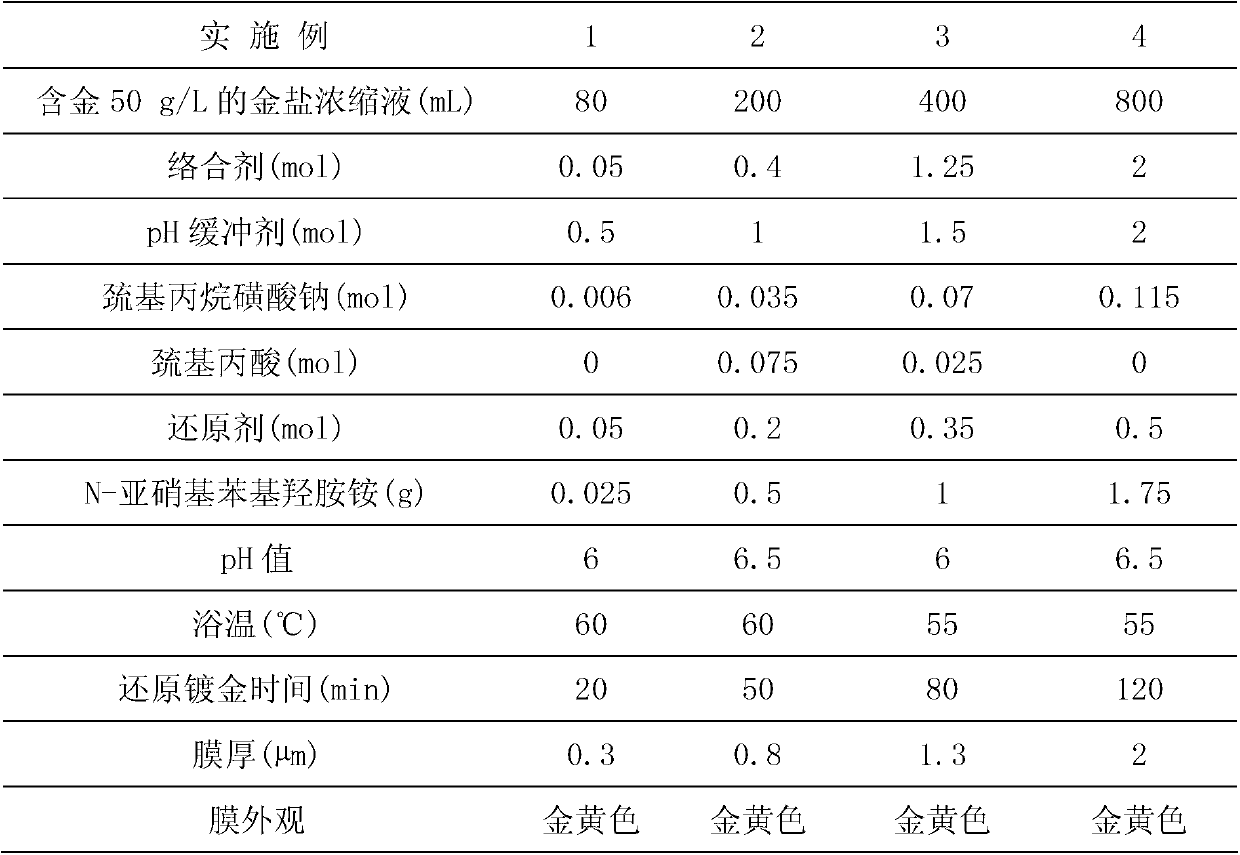

[0049] Table 2 prepares 5L reduction type gold plating solution meter

[0050]

[0051] The appearance color and crystallization state of the gold coating were evaluated visually, the bonding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com